Method for measuring trace elements in high titanium high boiler slag

A medium and trace element, high titanium blast furnace slag technology, applied in material excitation analysis, thermal excitation analysis, etc., can solve the problems of incomplete sample decomposition, inaccurate measurement results, low measurement results, etc., and achieve the dosage of reagents and samples. less, shorten the analysis time, overcome the effect of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Use the instrument:

[0034] Inductively coupled plasma atomic emission spectrometer (ICP-AES), model: TJA

[0035] 2. Use reagents:

[0036] The water used in the experiment was deionized water, and the chemical reagents were of analytical grade.

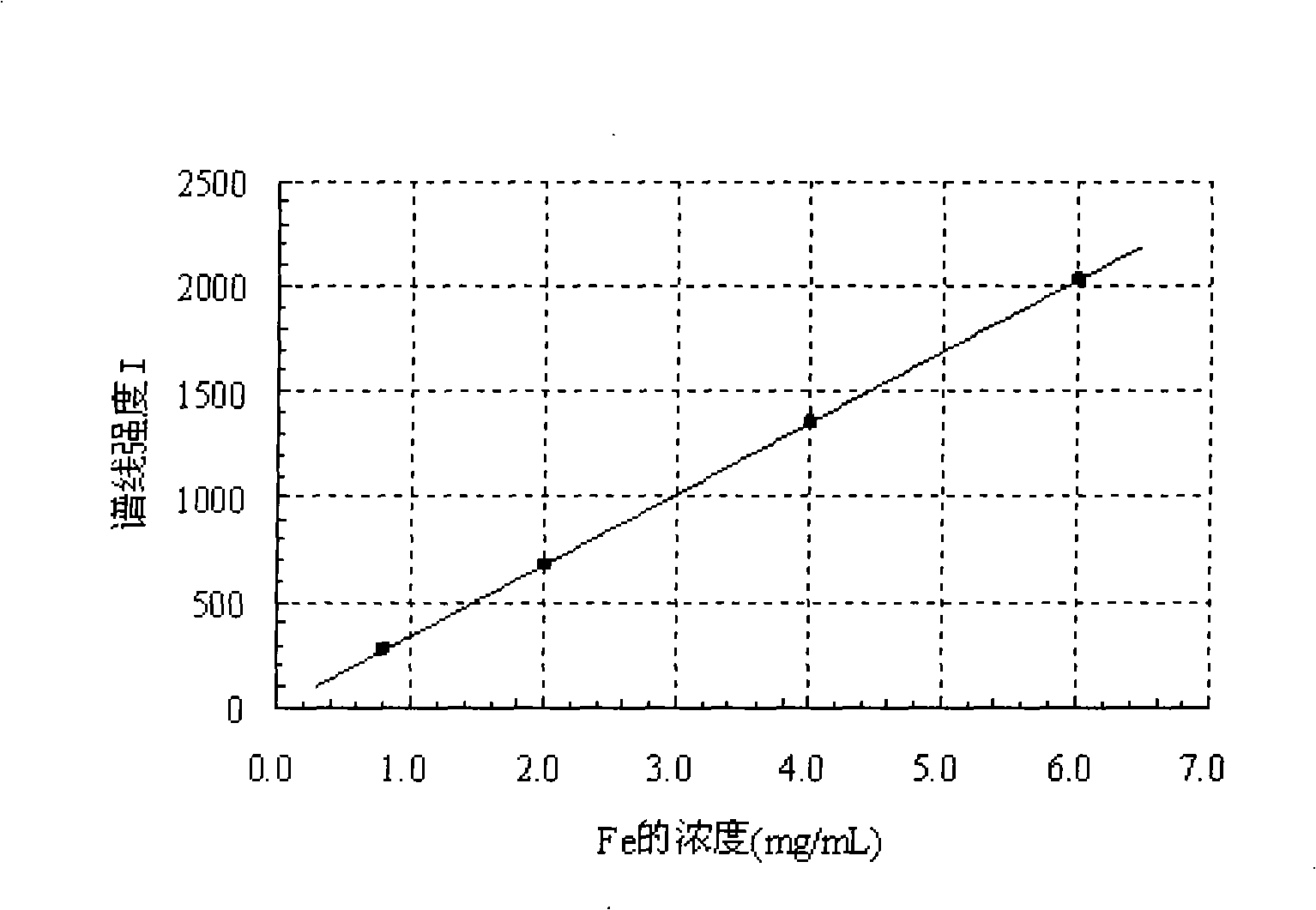

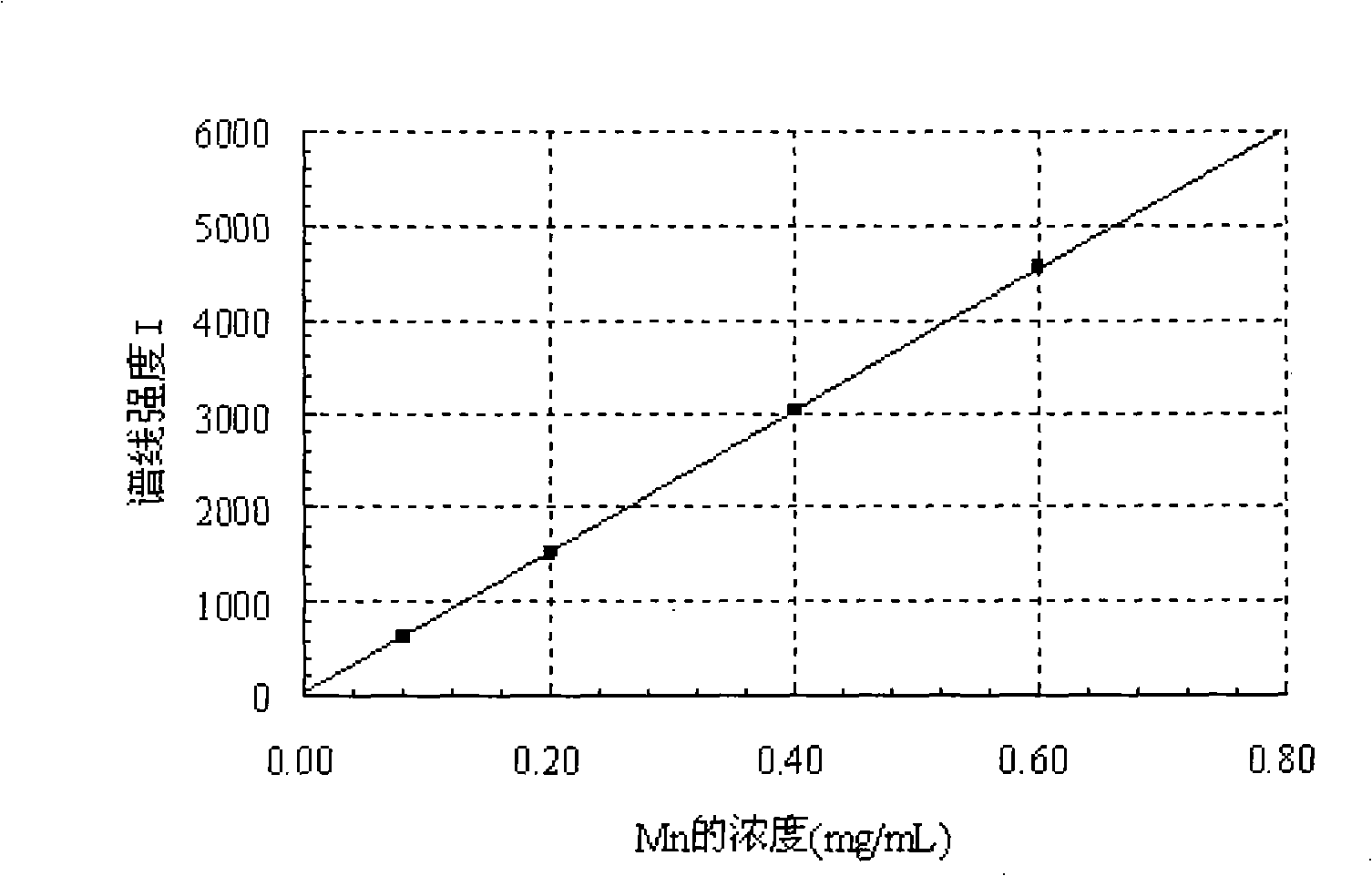

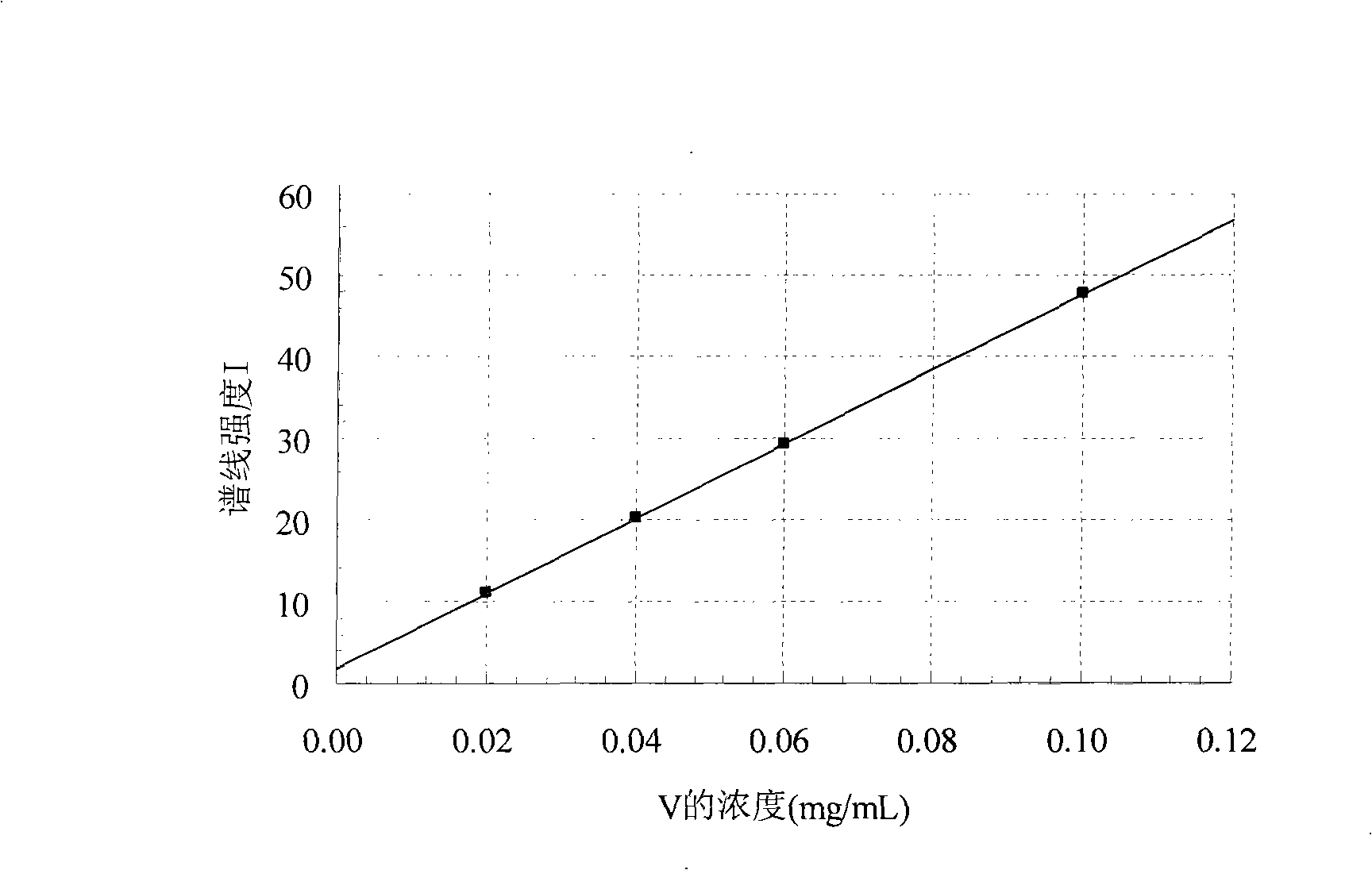

[0037] Iron, manganese, vanadium, phosphorus, aluminum, calcium, magnesium standard stock solution: use national standard reagent (GBW), the concentration is 1mg / mL. When measuring, add a certain amount of aluminum, calcium and magnesium standard solutions to the reagent blank, then add standard solutions of different concentrations of measurement elements, and set the volume to 250mL to obtain a mixed standard solution, in which the concentration of iron is 6.4, 16, 32, 48μg / mL, manganese concentrations are 0.64, 1.6, 3.2, 4.8μg / mL, vanadium concentrations are 0.16, 0.32, 0.48, 0.8μg / mL, phosphorus concentrations are 0.064, 0.128, 0.320, 0.640μg / mL mL.

[0038] 3. Drawing of working curves for iron, manganese, vanadi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com