Double-separation type fluidized bed slag cooler

A slag cooler and sorting technology, which is applied to fluidized bed combustion equipment, fuel burning in a molten state, combustion type, etc., can solve the problems of large operating air volume, low water cooling ratio, and large proportion of bottom slag and coarse slag, etc. Achieve the effect of reducing operating air volume, improving adaptability, and improving operating safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

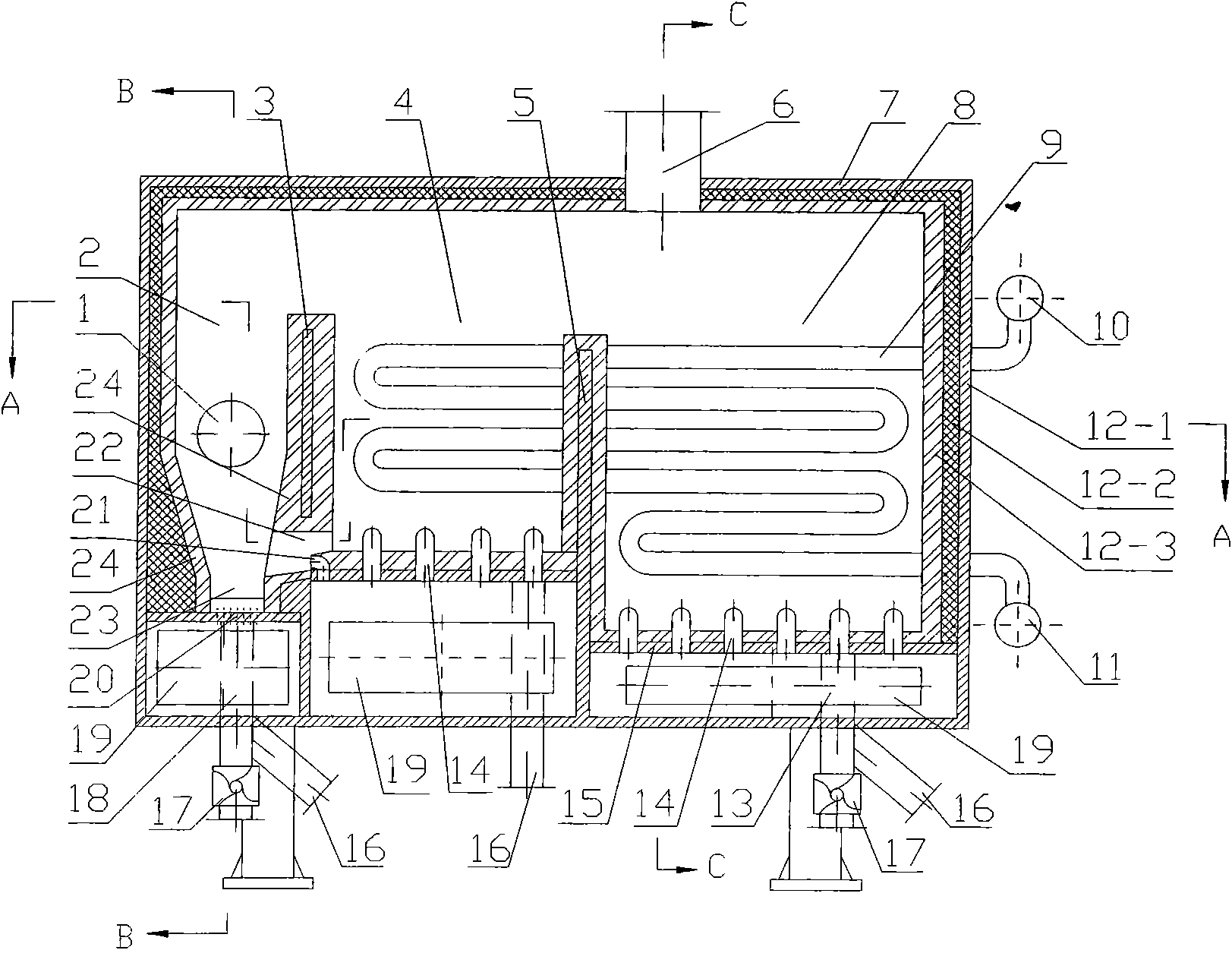

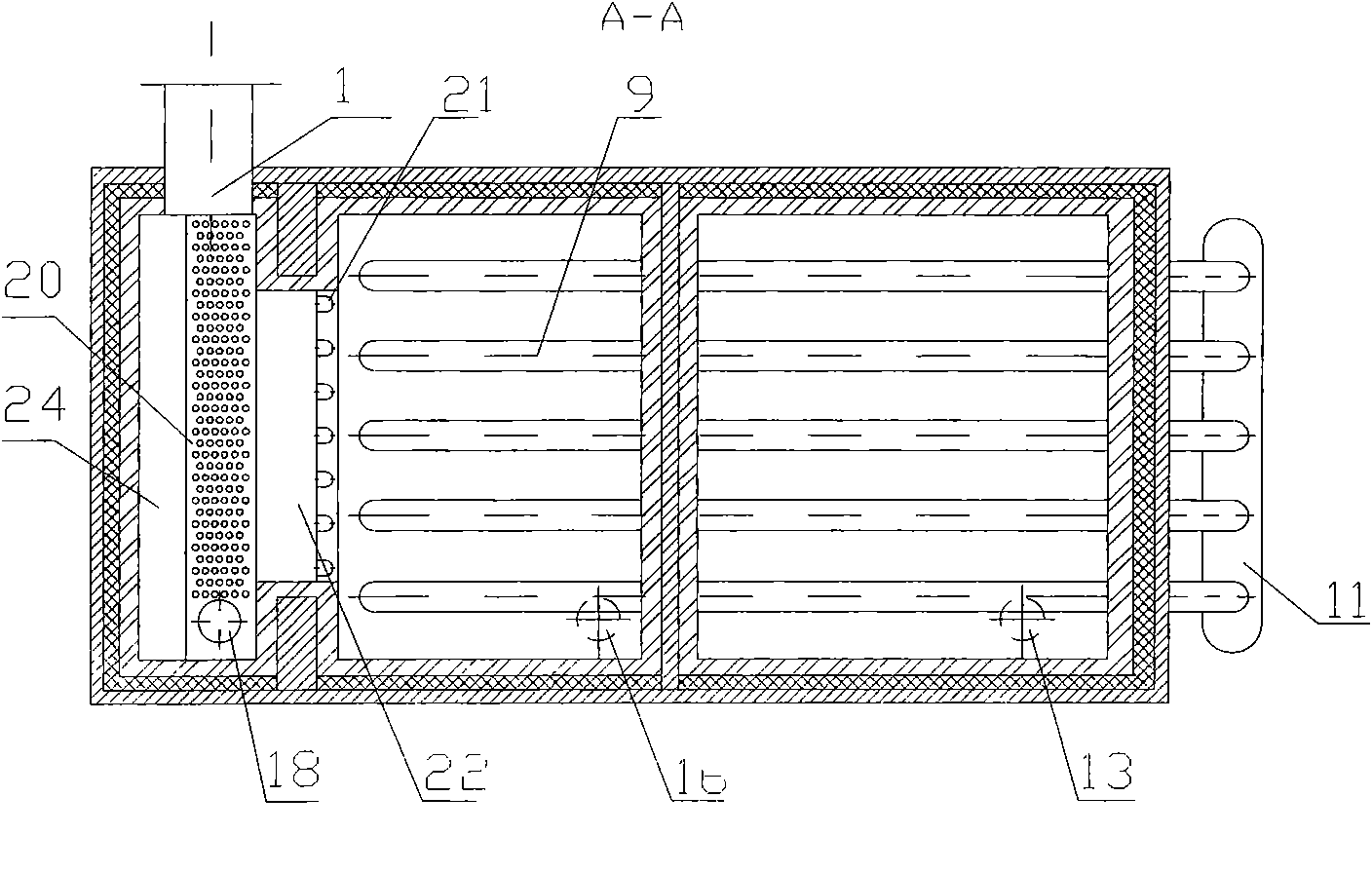

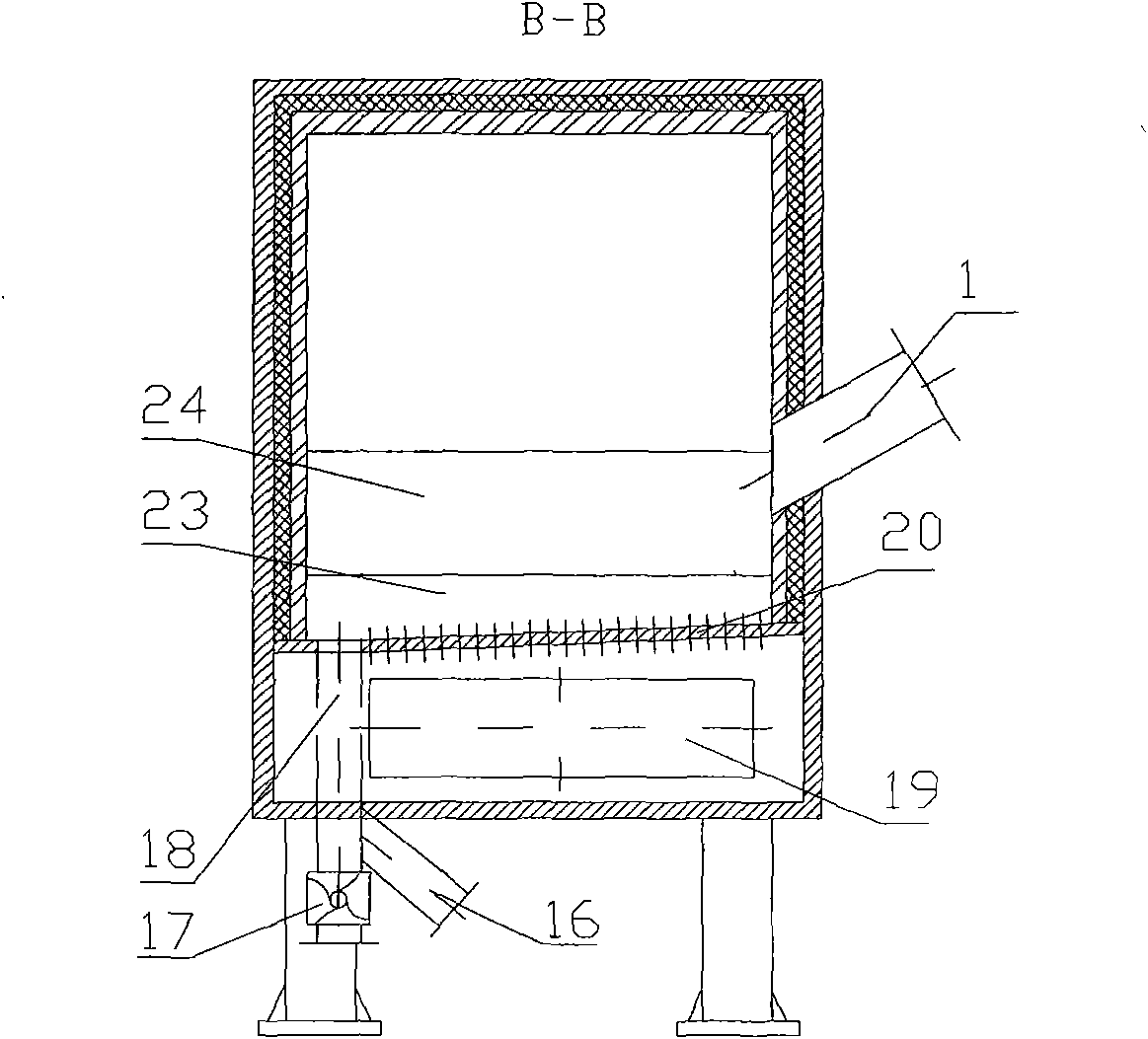

[0021] A kind of double sorting type fluidized bed slag cooler of the present embodiment such as figure 1 , figure 2 , image 3 and Figure 4As shown, the frame 12-1 of the main body 7 of the slag cooler is welded into a square body by steel plates, angle steels, and channel steels, and the inner side of the frame 12-1 is laid with thermal insulation materials and refractory materials successively. The thermal insulation layer 12-2 and the refractory layer 12-3 , the interior of the main body 7 of the slag cooler is arranged with a first partition wall 3 and a second partition wall 5, and the first partition wall 3 and the second partition wall 5 divide the internal space of the main body 7 of the slag cooler into three cooling chambers whose upper part communicates , the cooling bin at the left end is the sorting bin 2, the cooling bin in the middle is the circulation bin 4, and the cooling bin at the right end is the water cooling bin 8; independent air chambers 19 are se...

Embodiment 2

[0023] A combined double-separation fluidized bed slag cooler in this embodiment is as follows: Figure 5 , Figure 6 and Figure 7 As shown, when the design output is relatively large, a double-separation type fluidized bed slag cooler of the above-mentioned embodiment 1 is used as an independent module, consisting of 3 (or more, Figure 5 , Figure 6 and Figure 7 It is composed of 3) modules connected in series. Starting from the side where the slag feed pipe 1 is located, there are first-level modules, second-level modules and third-level modules in sequence. At this time, an inter-group partition wall 25 is installed between the corresponding cooling bins of the modules at all levels. For the sorting bin 2, the partition wall 25 between groups completely separates the upper part of the adjacent module sorting bin 2, and keeps the lower part connected, which can not only ensure that the coarse slag can be smoothly discharged from the slag cooler, but also prolong the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com