Equal-bed pressure cold slag fluidized bed of circulating fluidized bed boiler and operation method thereof

A technology of circulating fluidized bed and cold slag fluidized bed, which is applied in the directions of fluidized bed combustion equipment, combustion method, and fuel burned in a molten state, can solve the problems of large slag particle size, reduced thermal efficiency, and inability to use it. The effect of reducing carbon content in slag discharge, improving combustion efficiency and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

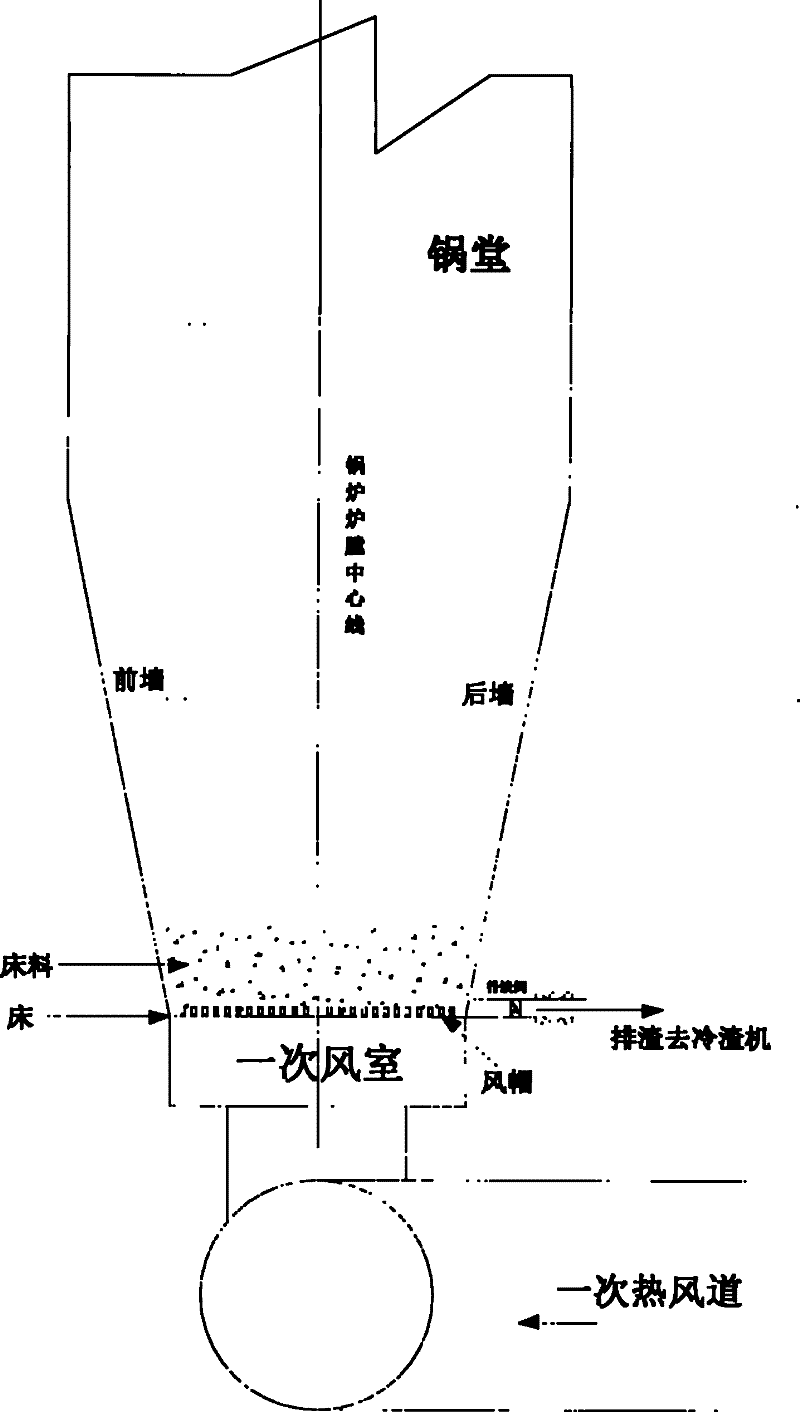

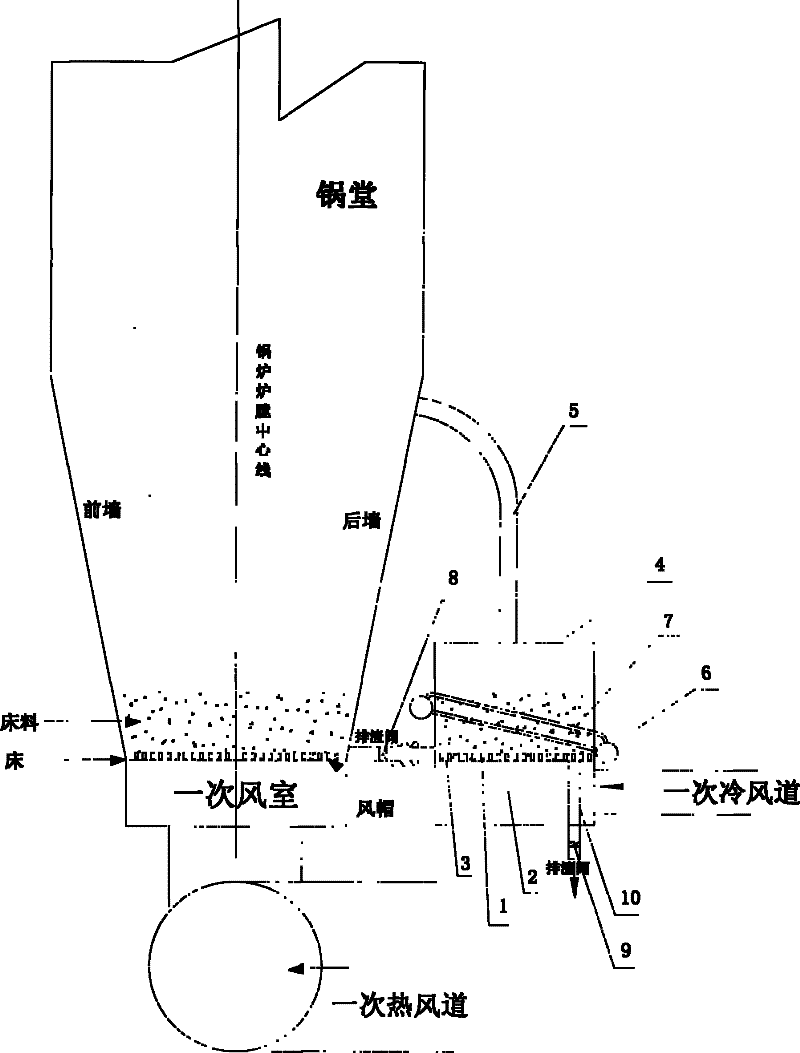

[0035] As shown in the figure, the equal-bed pressurized slag fluidized bed and operation method of the circulating fluidized bed boiler according to the present invention include a directional air cap 1, a primary cold air chamber 2, a bed 3, a rectangular shell 4, and a hot air pipe 5. Water cooling header 6, water cooling pipe row 7, boiler slag discharge valve 8, cold slag fluidized bed slag discharge valve 9, cold slag fluidized bed slag discharge pipe 10.

[0036] 1. The cold slag fluidized bed 3 is 10mm lower than the boiler fluidized bed during installation, and the boiler fluidized bed expands downward by about 150mm when it is in a hot state. At this time, it is basically the same as the elevation of the cold slag fluidized bed.

[0037] 2. The multi-drain cold pipe row 7 is buried in the material layer of the cold slag fluidized bed to realize sufficient heat exchange between water and slag, and the slag can be cooled to below 100°C. The water-cooling header 6 suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com