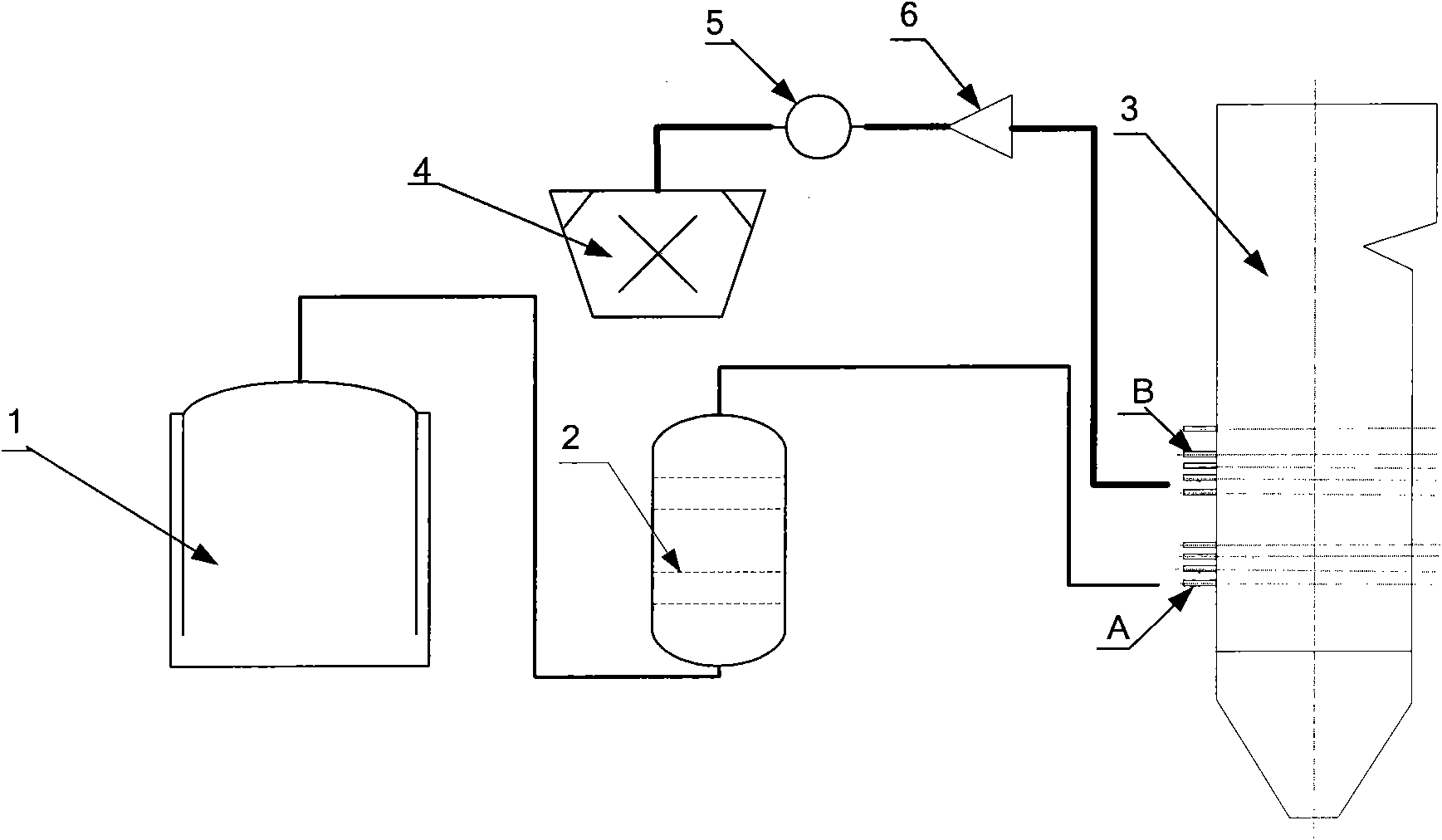

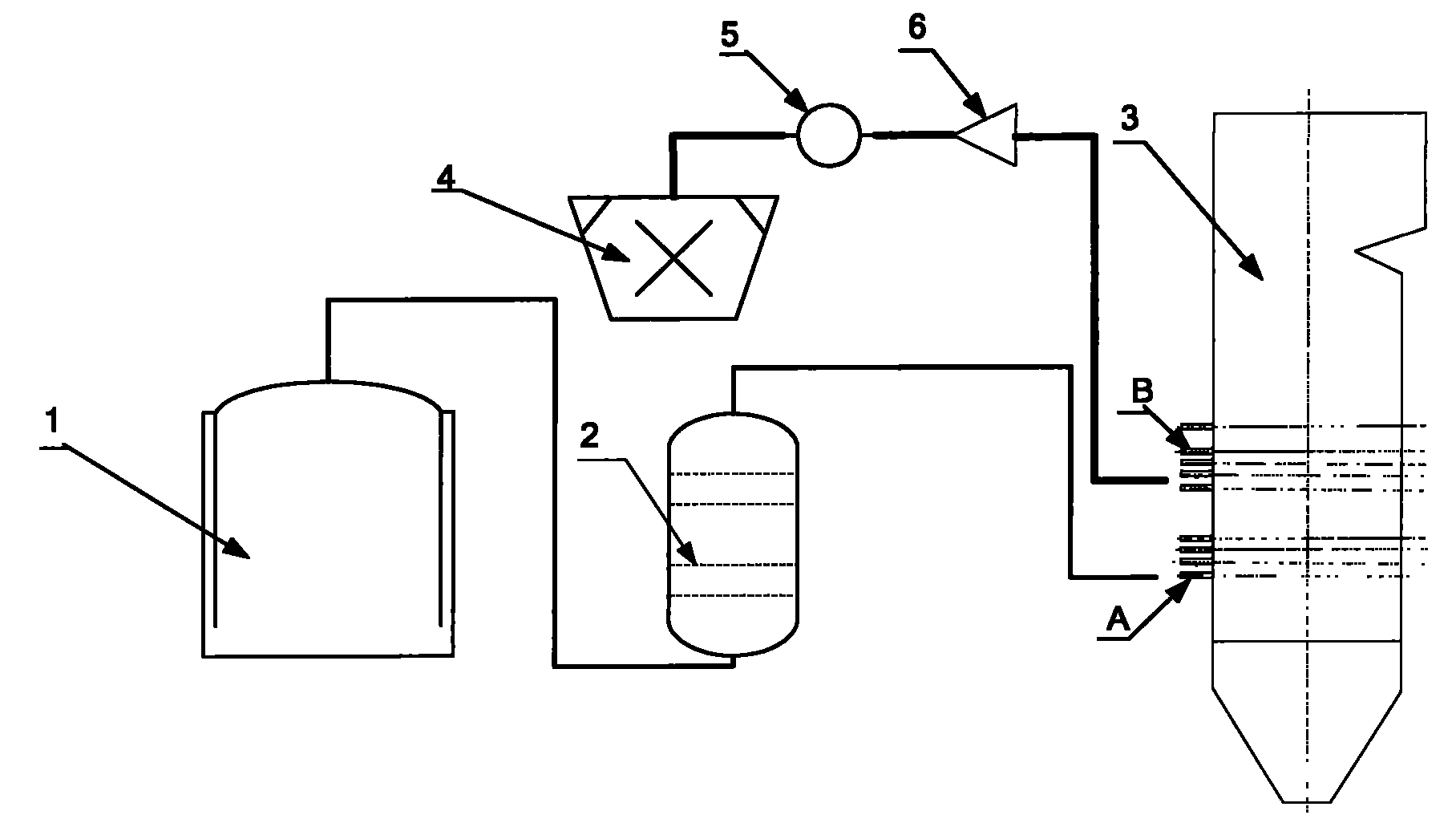

Biomass gas and coal dust mixed combustion process

A biomass gas and biomass technology, which is applied in the direction of burners, joint combustion mitigation, lighting and heating equipment, etc., can solve the problems that co-combustion technology does not pay attention to biomass and coal co-combustion technology, so as to reduce the generation of NO, The effect of reducing emission levels and alleviating slagging in the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Taking the 600MW unit boiler of a power plant as an example, the four-corner tangential combustion method is adopted, the coal consumption is 116.37kg / s, the low-level calorific value of coal is 14.7MJ / kg, and the composition of the biomass gasification gas by volume ratio is : CO: 25.5%, H 2 : 18.5%, CH 4 : 1%, CO 2 : 5.3%, N 2 : 49.7%, when the blending amount is 200,000 tons / year, the blending ratio is 5%.

Embodiment 2

[0024] When 400,000 t / y (combustion ratio is 8%), biomass gasification gas is injected from biomass gas nozzle A, the nozzle is 0.705m long and 0.305m wide, and the cross-sectional area of biomass gas injection is 1.72m 2 , the injection speed is 20.67m / s, and the NO removal rate can reach 60%; when the blended firing rate is 750,000 t / y (the blended firing ratio is 15%), the injection cross-sectional area is 1.72m 2 , the injection speed is 38.75m / s, and the NO removal rate can reach 66%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com