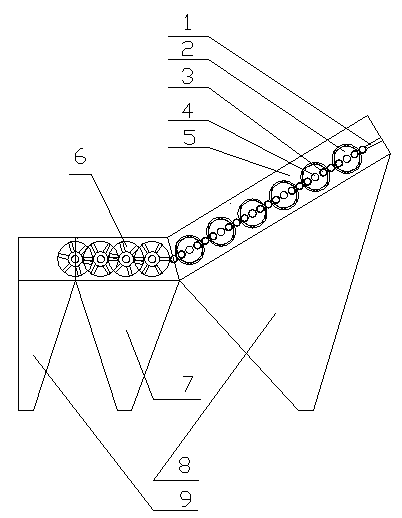

Biomass boiler slag separating machine

A biomass boiler and slag technology, which is used in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve problems such as insufficient enrichment rate, loss of utilization value, and physical heat loss of slag.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] The biomass boiler slag separation device provided by the present invention is tried out on a 75t / h combined grate steam boiler, and is installed on the outlet of the slag cooler. The fuel is a mixture of rice straw, rice husk and broken plywood. Among them, the rice straw is mixed with soil, and the industrial analysis results are 14.17% of total moisture, 66.33% of volatile matter, 4.57% of fixed carbon, and 14.93% of ash content. After 1 kg of rice straw is ash, it contains 22.8 grams of K element; the industrial analysis result of rice husk is Total moisture %, volatile matter 69.3%, fixed carbon 14.9%, ash content 10.8%; plywood industrial analysis results: total moisture 8.2%, volatile matter 36.7%, fixed carbon 49.3%, ash content 5.8%. When the slag separation device is not used, the slag contains a large amount of burnt large biomass and sticky coke, which can only be landfilled as hazardous waste. 11.3Kg of bulk biomass was manually sorted out of 100Kg of slag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com