Process and method for converting waste slag wholly of aluminum industry into ecological building material

A technology of ecological construction and craftsmanship, applied in the production of ceramic materials, solid waste management, sustainable waste treatment, etc., can solve problems such as high water content, environmental pollution, and large displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

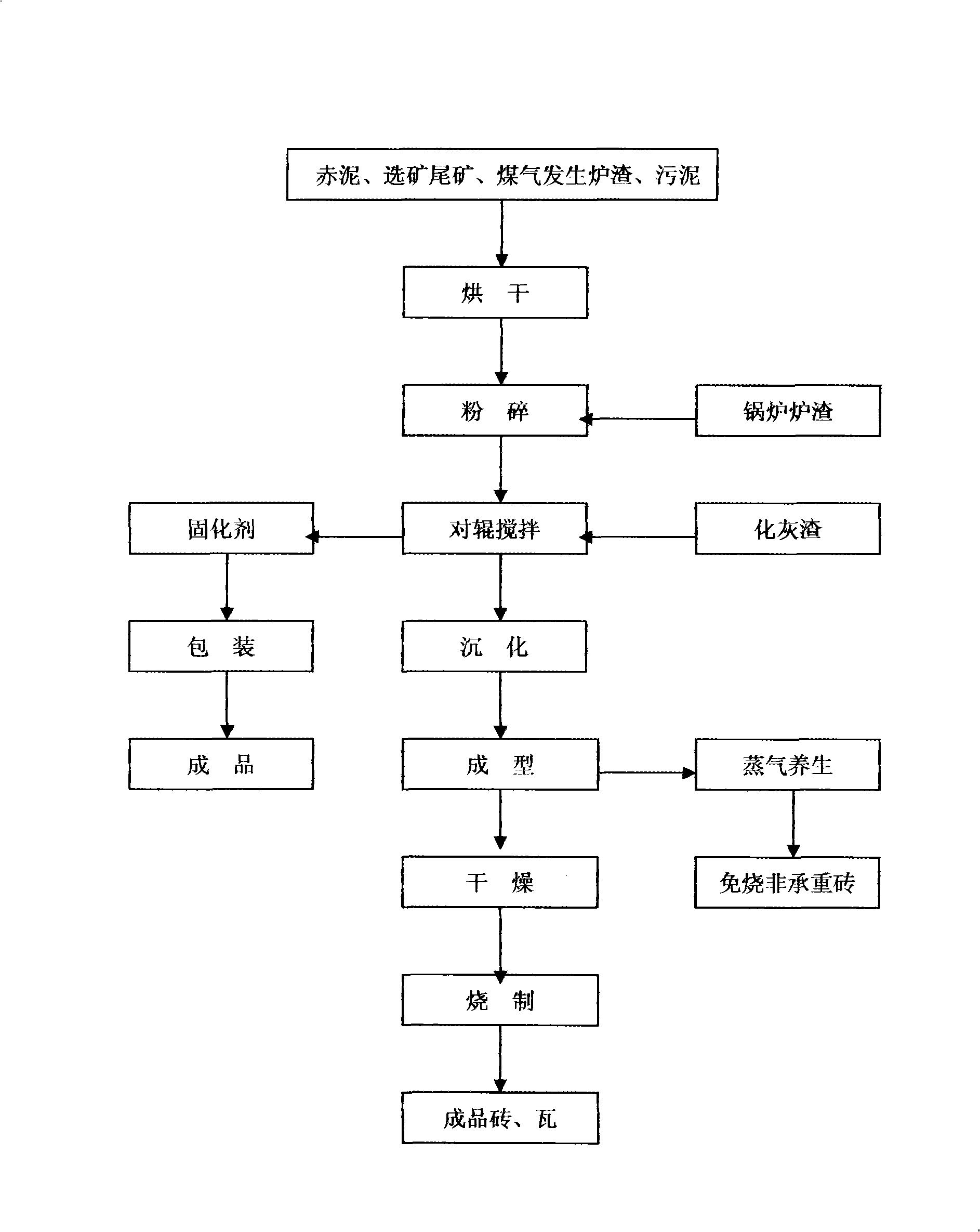

Method used

Image

Examples

example 1

[0010] Mixing ratio: red mud + gas generation slag + ash slag + trace additives = 25+52+23 (trace additives are)

[0011] (1) Drying of raw materials: According to the above mixing ratio, the raw materials are sent to the tunnel kiln drying chamber for drying to 4% water content.

[0012] (2) Raw material pulverization: grind into powder with a ball mill, and the particle size passes through a 80-mesh sieve.

[0013] (3) Mixing and stirring: the above-mentioned raw materials are mixed evenly in two-stage and double-layer with a double-roller mixer.

[0014] (4) Finished product and packaging: The uniformly stirred mixture is sealed and packaged, which is the finished product of the curing agent.

[0015] The curing agent is used to replace all the lime, cement and sand and gravel in the subbase and base of the secondary road from Chalco to Yuntai Mountain in Jiaozuo City, and meets the requirements of the "Highway Engineering Quality Inspection and Evaluation Standard" after ...

example 2

[0017] Mixing ratio: red mud + gas generation slag + mineral processing tailings + sludge = 20+25+50+5 (mass ratio)

[0018] (1) Drying of raw materials: According to the above mixing ratio, the raw materials are sent to the tunnel kiln drying chamber for drying to 4% water content.

[0019] (2) Crushing of raw materials: crushing with a hammer crusher, particle size ≤ 1.0mm.

[0020] (3) Mixing and stirring: the above-mentioned raw materials are fully mixed, and after mixing, water is added to carry out two-stage double-layer stirring with a double-roller mixer, and the amount of water added during mixing and stirring is 12% to 16% of the weight of the mixture;

[0021] (4) Precipitation: Let the mixed materials rest for 24 hours.

[0022] (5) Extrusion molding: Extrude the above-mentioned mixture into strips with a two-stage vacuum brick extruder.

[0023] (6) cutting adobe: the above-mentioned extruded blank is cut into adobe with an automatic vertical strip cutter and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com