Method for fastening building materials together

a technology of adhesive membrane and building material, applied in the direction of film/foil adhesive, walls, ceilings, etc., can solve the problems of foot traffic, loose decking, etc., and achieve the effect of fast and convenient, sound deadening and structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

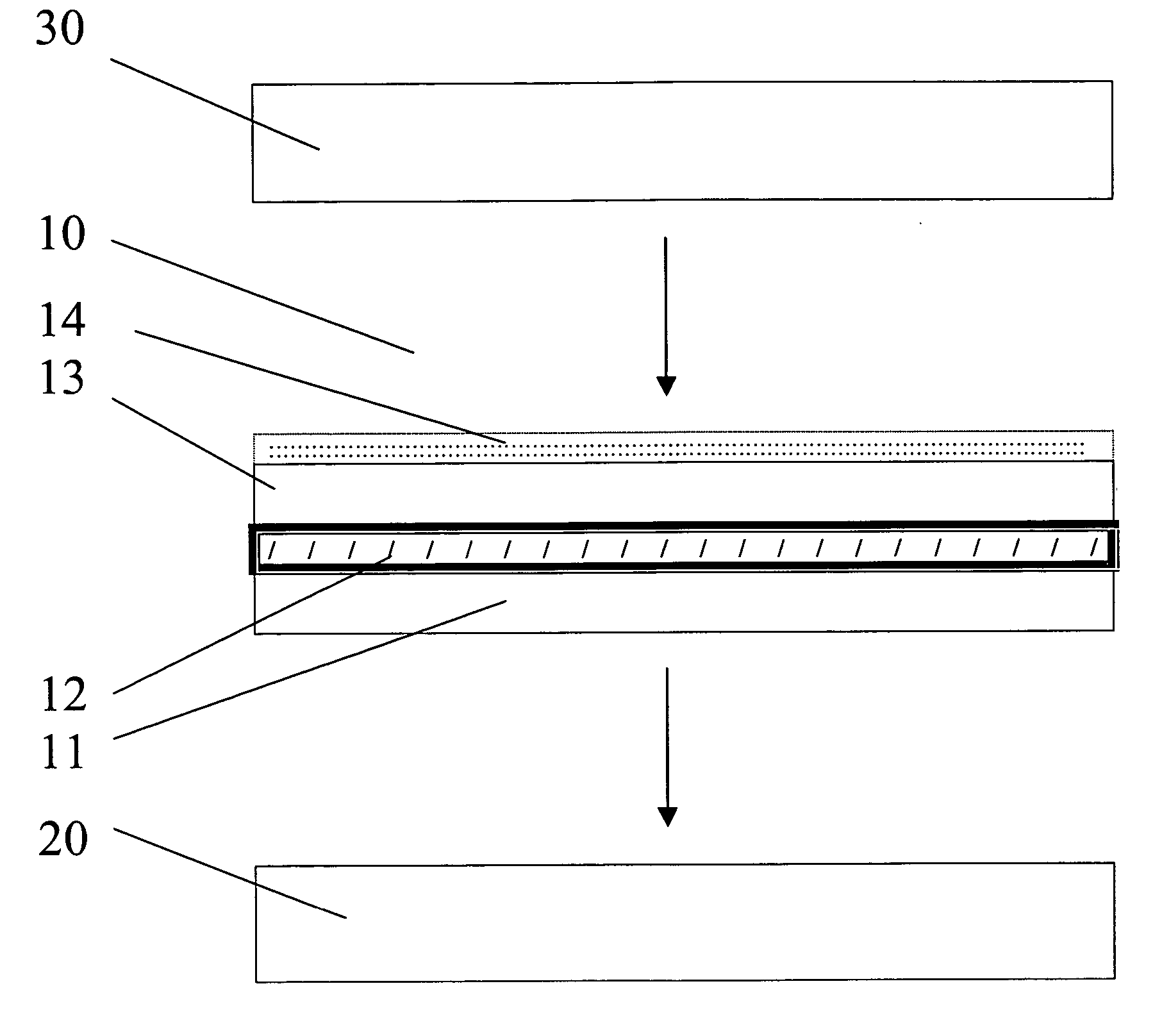

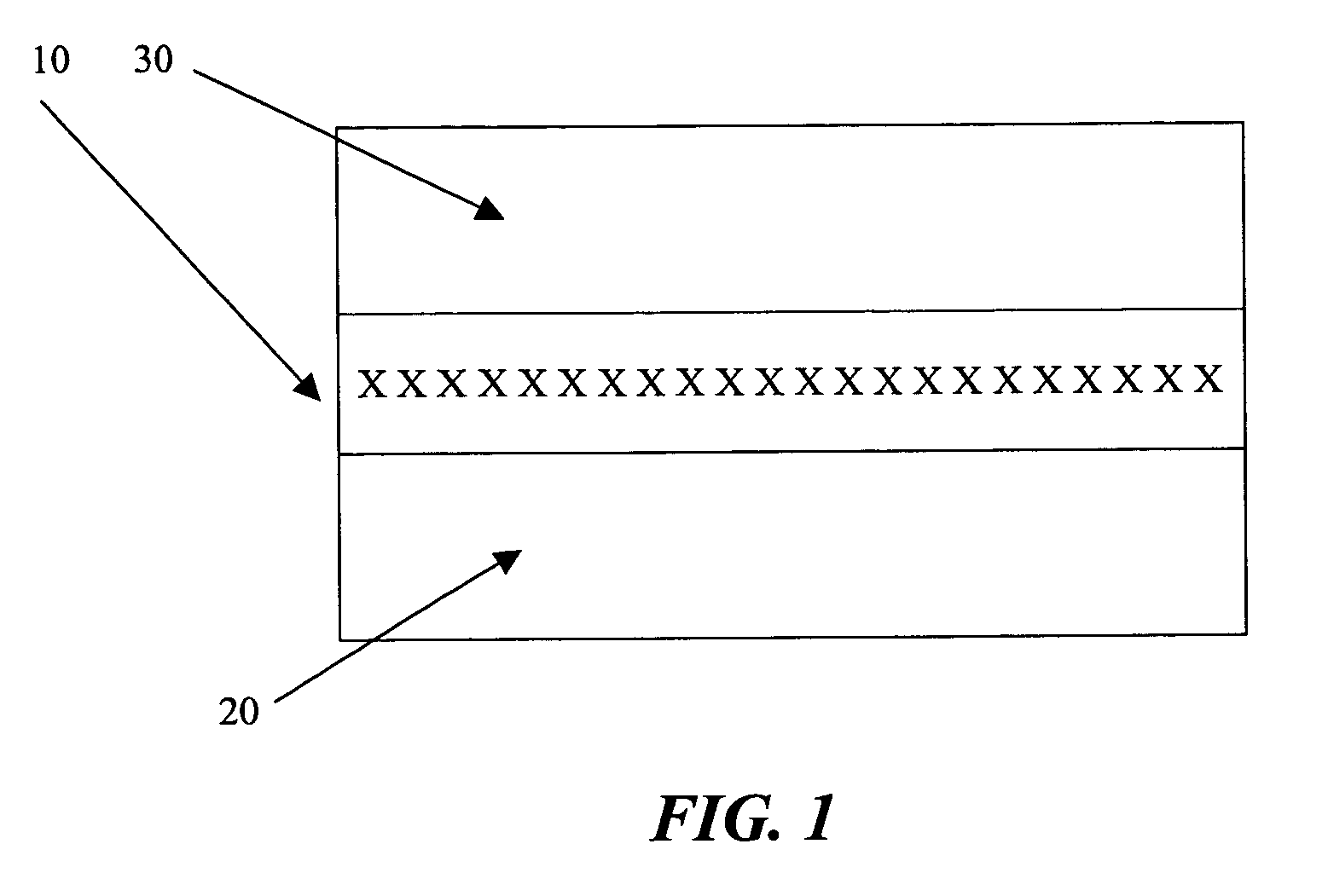

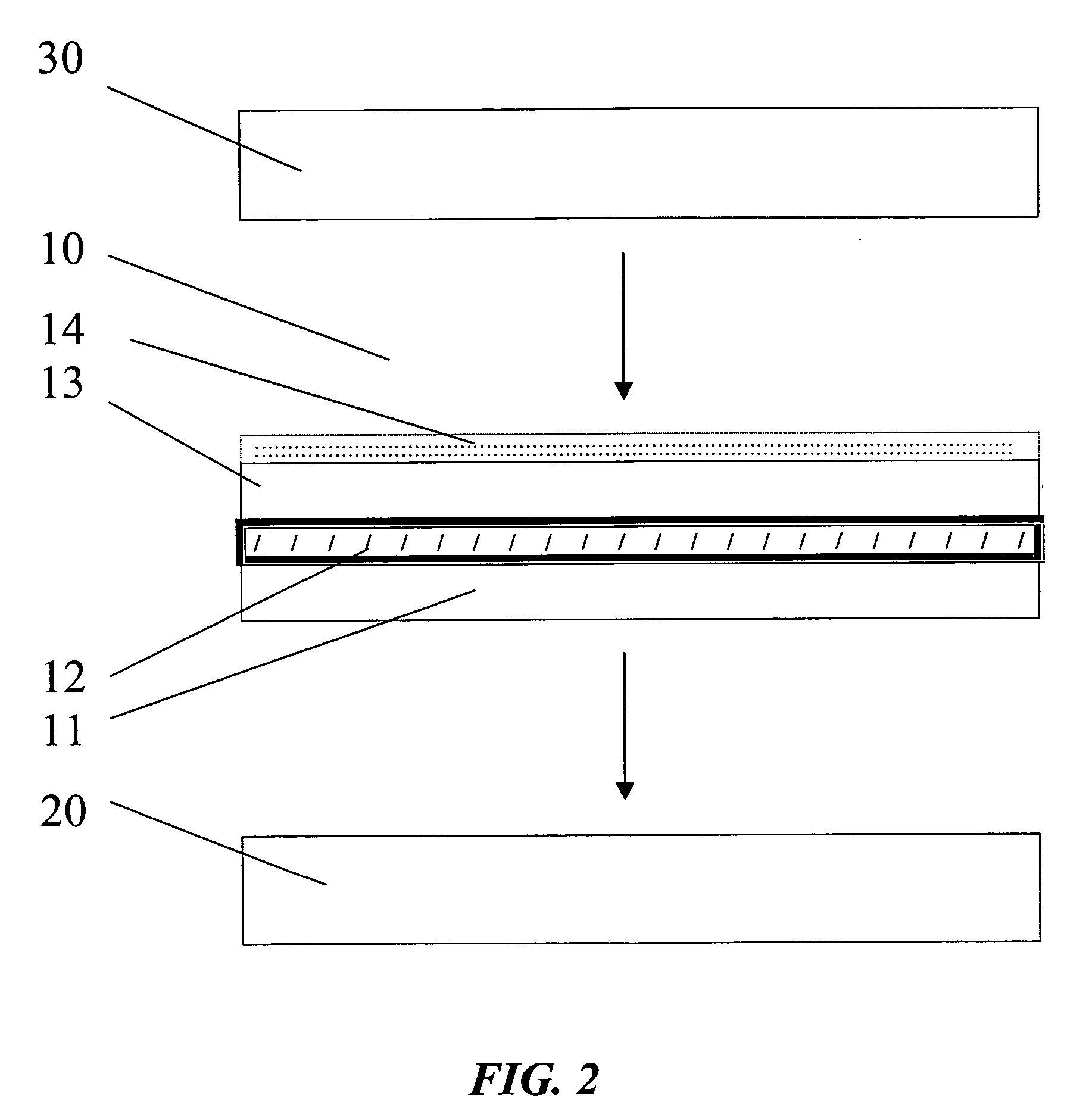

[0046] This example provides a demonstration that the less-initially-tacky pressure sensitive layer 13 (outermost, see e.g., FIG. 1) exhibits low initial adhesion value, but thereafter demonstrates stronger “aged” adhesion value (e.g., stronger adhesion after a period of time during which it is pressed against a substrate).

[0047] Exemplary less-initially-tacky pressure sensitive layers 13 exhibit an (initial) adhesion value of less than or equal to 0.5 pounds per lineal inch when tested in accordance with standard peel adhesion test, which is described again hereinbelow as follows. Preferably, the less-initially-tacky pressure-sensitive adhesive layers exhibit an initial adhesion value of less than or equal to 0.5 pounds per lineal inch when tested in accordance with a standard peel adhesion test. A 3″×8″ piece of two-sided tape is used. A release liner is left in contact with the pressure sensitive layer 11. The less-initially-tacky, pressure-sensitive adhesive layer 13 is applied...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Adhesion strength | aaaaa | aaaaa |

| Adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com