Water-cooling dry-type slag discharge device of pulverized coal boiler

A technology for dry slag discharge and pulverized coal boilers, which is applied to lighting and heating equipment, etc., can solve the problems of extrusion broken slag not being able to meet the uniform discharge particle size and broken grate, so as to improve labor hygiene conditions, reduce emissions, The effect of saving the occupied land area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

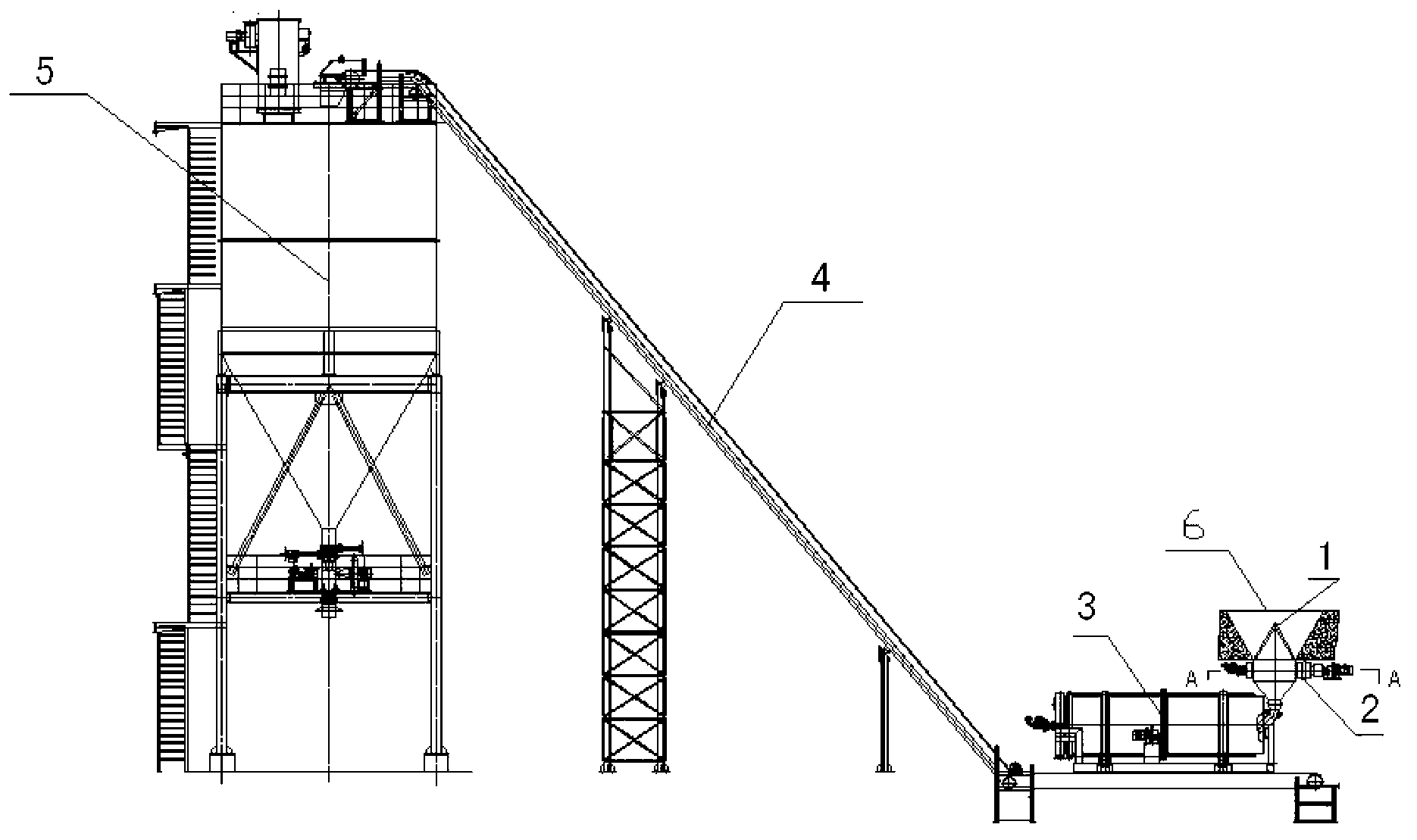

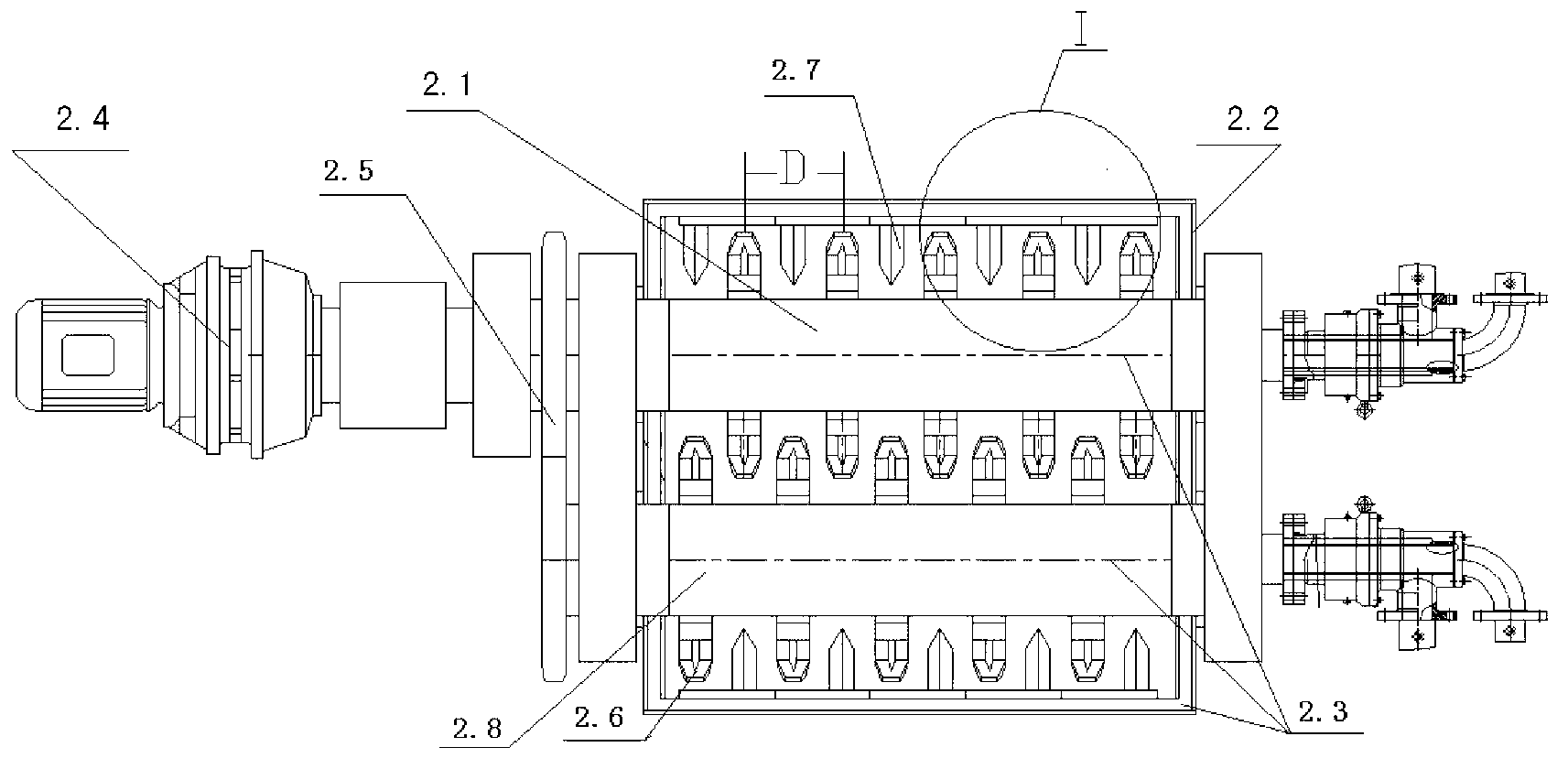

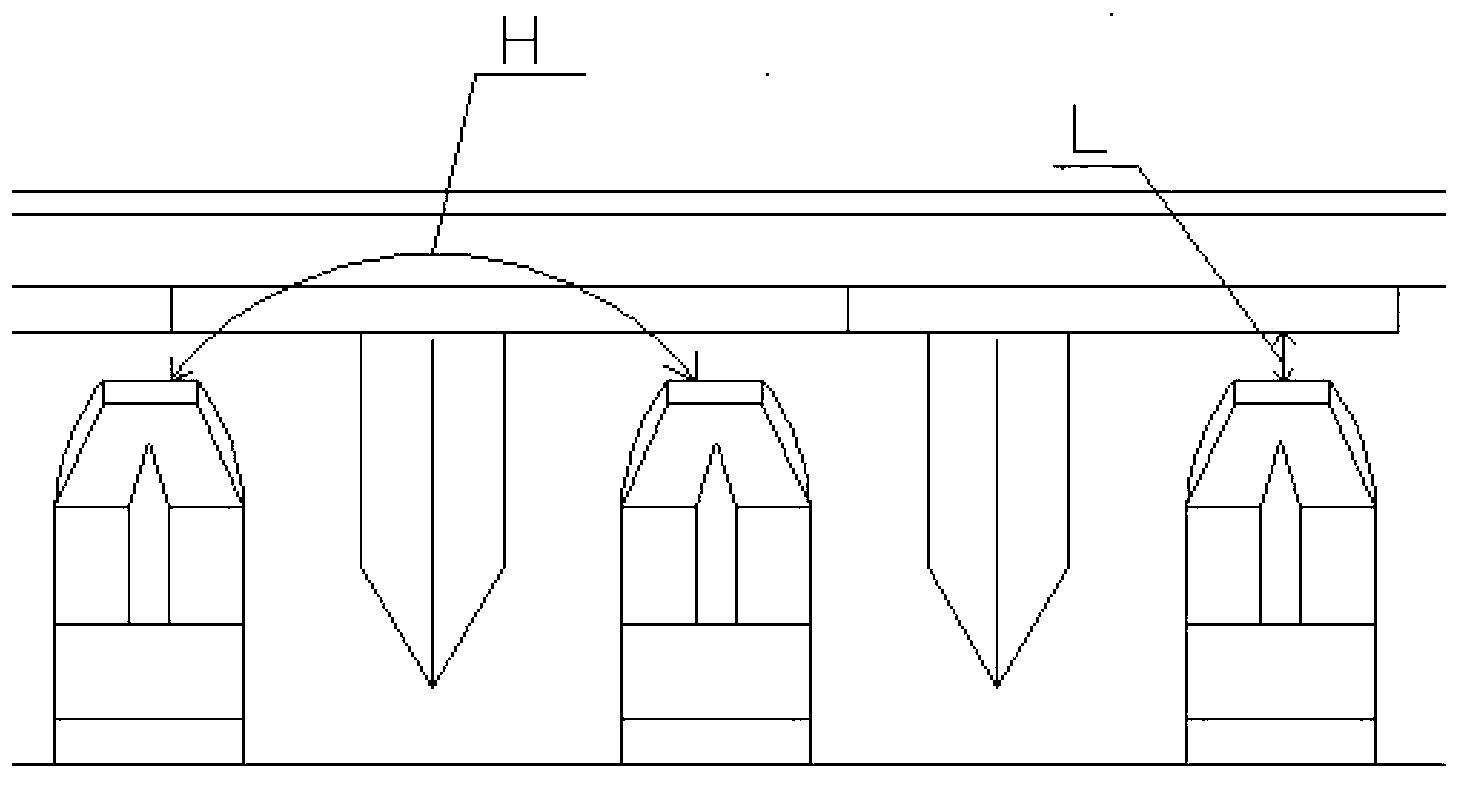

[0021] Such as figure 1 , 2 As shown, the pulverized coal boiler water-cooled dry slag discharge device provided by the present invention includes a drum slag cooler 3 and a slag conveying device 4 . The slag conveying device can be composed of a large-angle belt or a chain bucket conveyor. A slag crushing device is set between the boiler slag well 6 and the drum cooler 3. The slag crushing device provided in this embodiment is a high-temperature double-roller slag breaker 2. The outlet of the high-temperature double-roller slag breaker 2 is connected to the drum cooling The feed port of the slag machine 3 is connected, and the discharge port of the drum cold slag machine 3 is connected with the slag conveying device 4 . The high-temperature double-roller slag breaker includes two rotating rollers (2.1, 2, 8) driven by the transmission mechanism 2.4 to rotate in opposite directions. Several slag-breaking teeth 2.6 are arranged on the surface of the rotating rollers along the...

Embodiment 2

[0027] Such as Figure 5 As shown, when transforming the pulverized coal boiler system in use, it is necessary to determine the transformation plan according to the actual space on site. When the height is insufficient, a water-cooled spiral slag cooler 7 can be added between the high-temperature double-roller slag breaker 2 and the drum slag cooler 3 to increase the elevation of the cooled ash and carry out relay cooling.

[0028] Through the water-cooled dry-type slag discharge device for pulverized coal boilers provided by the present invention, the ash and slag can be broken into slag of <50mm, and the hot slag can be indirectly cooled by boiler feed water, and the heat can be recovered for reuse, and the temperature of the ash and slag can be lowered. To ≤100℃, in order to facilitate the use of inclined belt or chain bucket conveyor to transport to the slag bin for storage. Recycling the low-level heat energy lost by wet chilling can effectively avoid a large amount of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com