Method for automatically recycling and treating carbon residue from boiler slag of coal gasification

A technology for automatic recovery of coal gasification slag, applied in the petroleum industry, solid fuel, solid waste removal and other directions, can solve problems such as increased operating costs, complicated processes, and high slag content, achieve great environmental benefits, and eliminate dust pollution. , the effect of creating economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

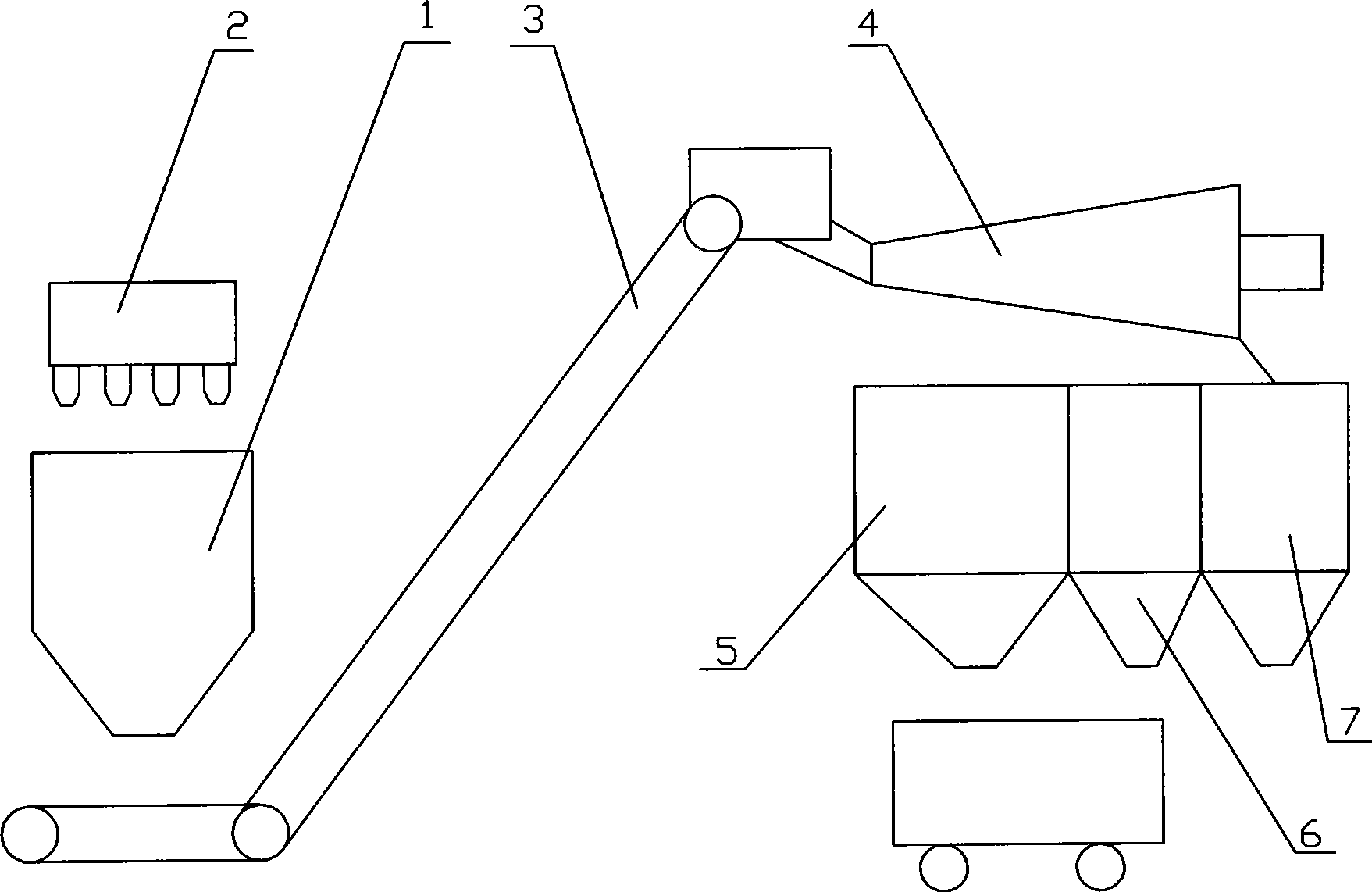

[0007] The flow process of the present invention is as follows: the mixed slag discharge of small grain slag, residual carbon briquettes and bonded slag body produced by the gasifier can be carried out manually or automatically, continuously or intermittently, and the good slag is transported to the slag yard, directly Put the mixed slag into the silo (1), and set the spray device (2) on the top of the silo (1) to adjust the mixed slag by adding water; (1) Stay for a period of time in order to facilitate the full cracking of the bonded slag body. The residence time is about 0.5 to 5 hours, and the optimal residence time is 1 to 2 hours. The large sticky slag is fully decomposed and cracked in the silo (1), and the slag and residual carbon are separated by cracking, and then enters the chain bucket conveyor belt (3) from the bottom of the silo (1) and sends it to the drum screen (4 ) or a vibrating sieve; the drum sieve (4) sieves the small slag and bonded slag in the original ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com