Method for relieving boiler slagging by using fly ash circulation

A fly ash and boiler technology, which is applied in the field of using fly ash circulation to alleviate boiler slagging, can solve problems such as boiler slagging that cannot be fundamentally solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

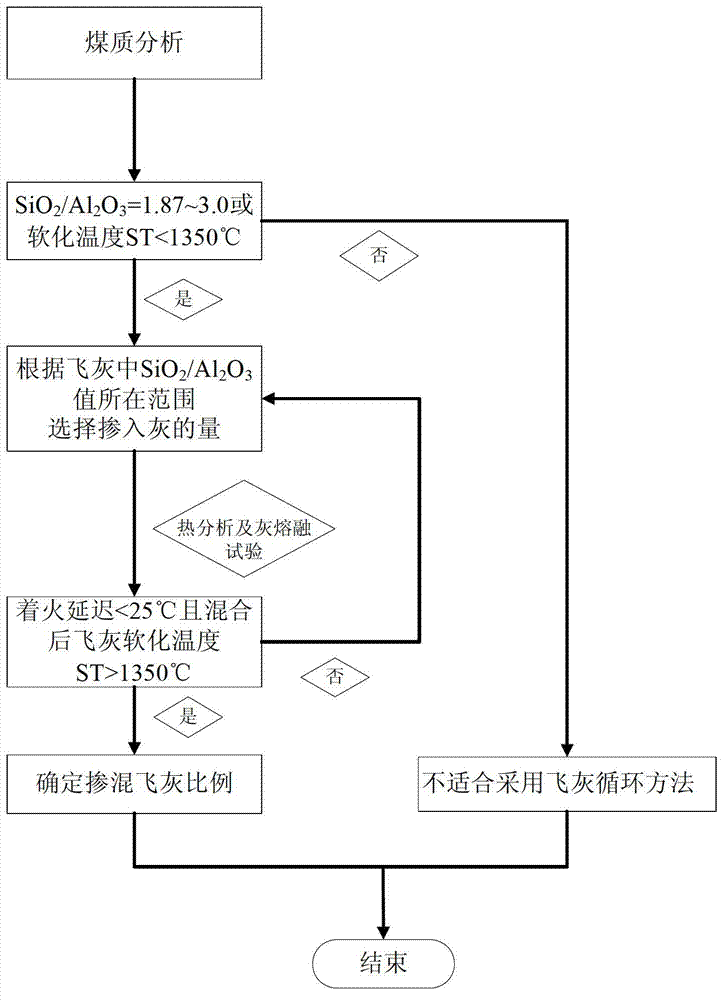

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0018] see figure 1 , the method of the present invention is as follows:

[0019] 1) Coal-fired fly ash detection: detect coal-fired fly ash, if SiO in coal-fired fly ash 2 / Al 2 o 3 When the value is 1.87~3.0 or the softening temperature ST of coal-fired fly ash is below 1350°C, then add fly ash to the raw coal; otherwise, no fly ash is added to the raw coal;

[0020] 2) Determine the amount of fly ash mixed: according to the SiO in coal-fired fly ash 2 / Al 2 o 3 Select the amount of fly ash mixed with the value of , that is, the amount of fly ash mixed into raw coal;

[0021] 3) If the fuel thermal analysis test after blending fly ash shows that the ignition temperature delay after blending does not exceed 25°C, and the softening temperature ST of the ash formed after blending fly ash is not lower than 1350°C, then the blending The amount of blended...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com