Efficient wet type electric dedusting and purifying device and method for smoke obtained after wet desulphurization

A wet electrostatic precipitator and wet desulfurization technology, which is applied in chemical instruments and methods, electrostatic effect separation, external electrostatic separators, etc. Distribution, collection efficiency improvement, and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

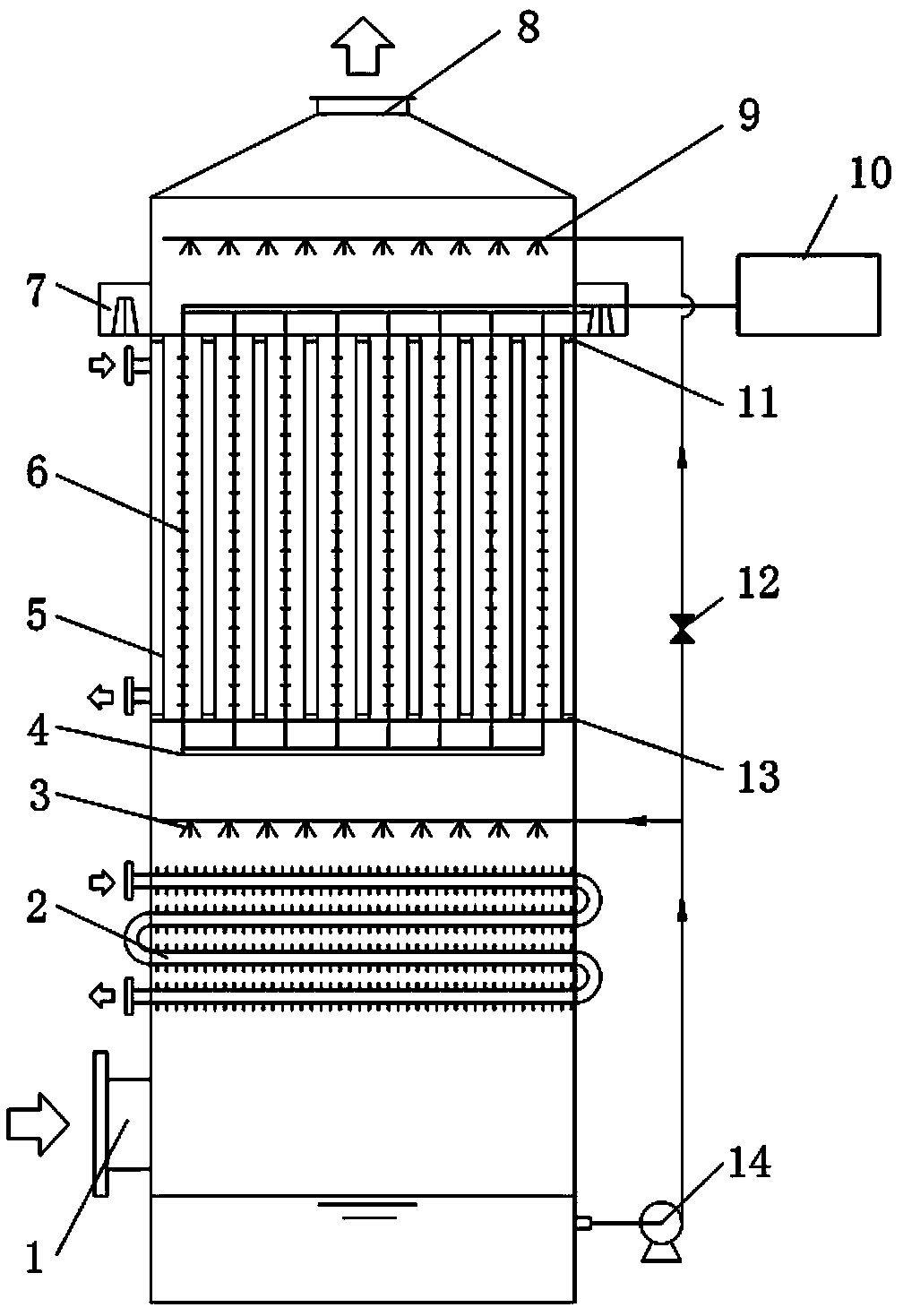

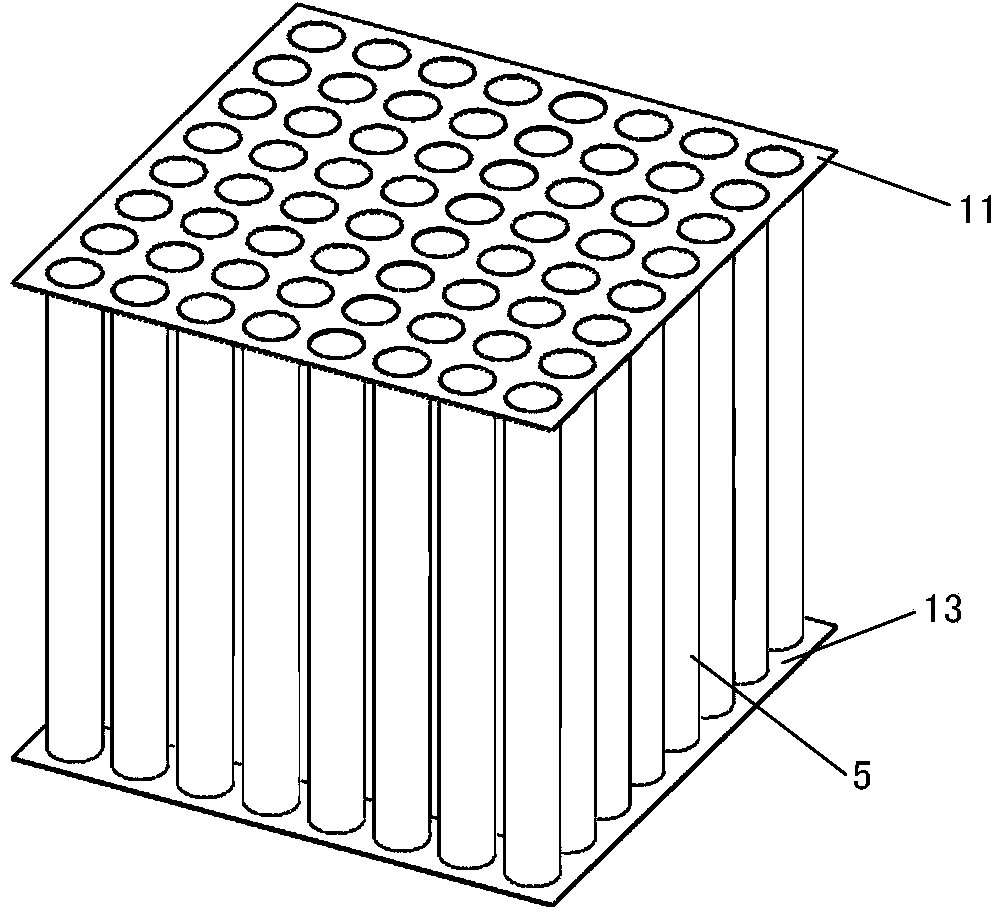

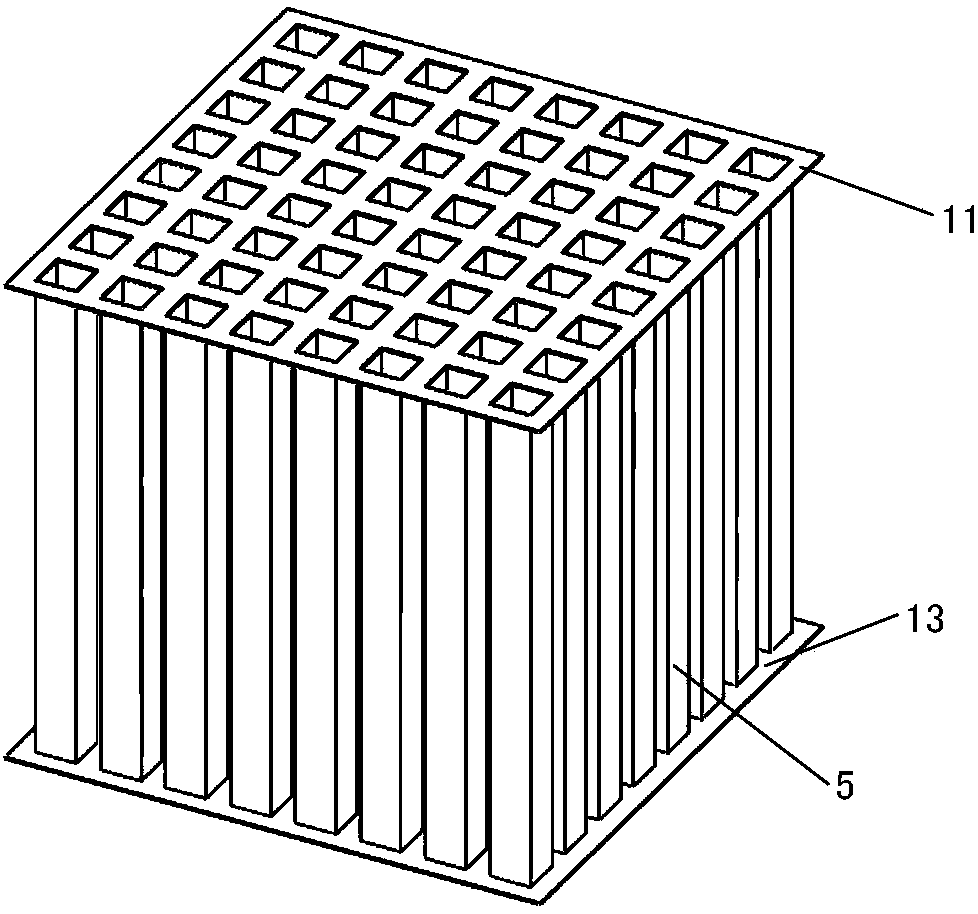

[0035] Such as figure 1 As shown, the high-efficiency wet electrostatic precipitator purification device for flue gas after wet desulfurization of the present invention includes a gas inlet 1, a heat exchange tube 2, several humidifying nozzles 3, and a cathode fixing frame 4 arranged in the housing in sequence from bottom to top , several dust collecting pipes 5, several cleaning nozzles 9, an insulating box 7 and a gas outlet 8, wherein, in combination as figure 2 , 3 , 4, the upper and lower ends of several dust collection pipes 5 are respectively sealed and connected with the upper flower plate 11 and the lower flower plate 13 to form a dust collection tube bundle; several discharge electrode wires 6 are respectively built in the dust collection pipe 5, by The cathode fixed frame 4 is fixed; the cathode fixed frame 4 is connected with the high-voltage power supply 10 outside the housing.

[0036] After the flue gas enters the device, it must first pass through the heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inscribed circle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com