Method for treating desulfurization waste liquid of wet oxidation method

A technology for wet oxidation and desulfurization waste liquid, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., to achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

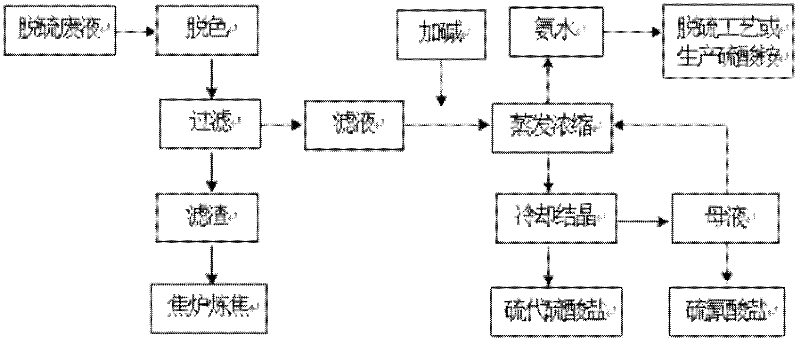

Image

Examples

Embodiment Construction

[0012] Send about 10L of desulfurization waste liquid from the coking plant into the desulfurization liquid storage tank, (desulfurization waste liquid composition: ammonium thiocyanate: 163g / L; ammonium thiosulfate: 150g / L; suspended sulfur: 4g / L; volatile ammonia: 7.5g / L; PDS: 24ppm; PH: 8.9), settle for 12 hours and filter into the decolorization tank, add activated carbon, stir evenly, the decolorization time is about 6 hours, and the temperature is controlled at 35°C. After decolorization is completed, filter, and the filtrate changes from green or light green to colorless or light yellow transparent liquid. The filter residue is sent to the coke oven for coking.

[0013] The decolorized filtrate enters the concentration kettle, and about 1.6 kg of solid NaOH is added therein, stirred evenly, and the pH of the solution is controlled at 8.9. Using the exothermic heat from the dissolution of solid NaOH, the temperature of the liquid in the kettle is automatically raised to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com