Continuous biomass pyrolytic carbon gas-oil poly-generation system

A biomass and pyrolysis gas technology, which is applied in the field of biomass pyrolysis polygeneration system, can solve the problems of uneven heating of biomass raw materials, different quality of coke products, and pollution of liquid products, so as to reduce secondary pollution caused by possibility, shortening the time required for production, and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

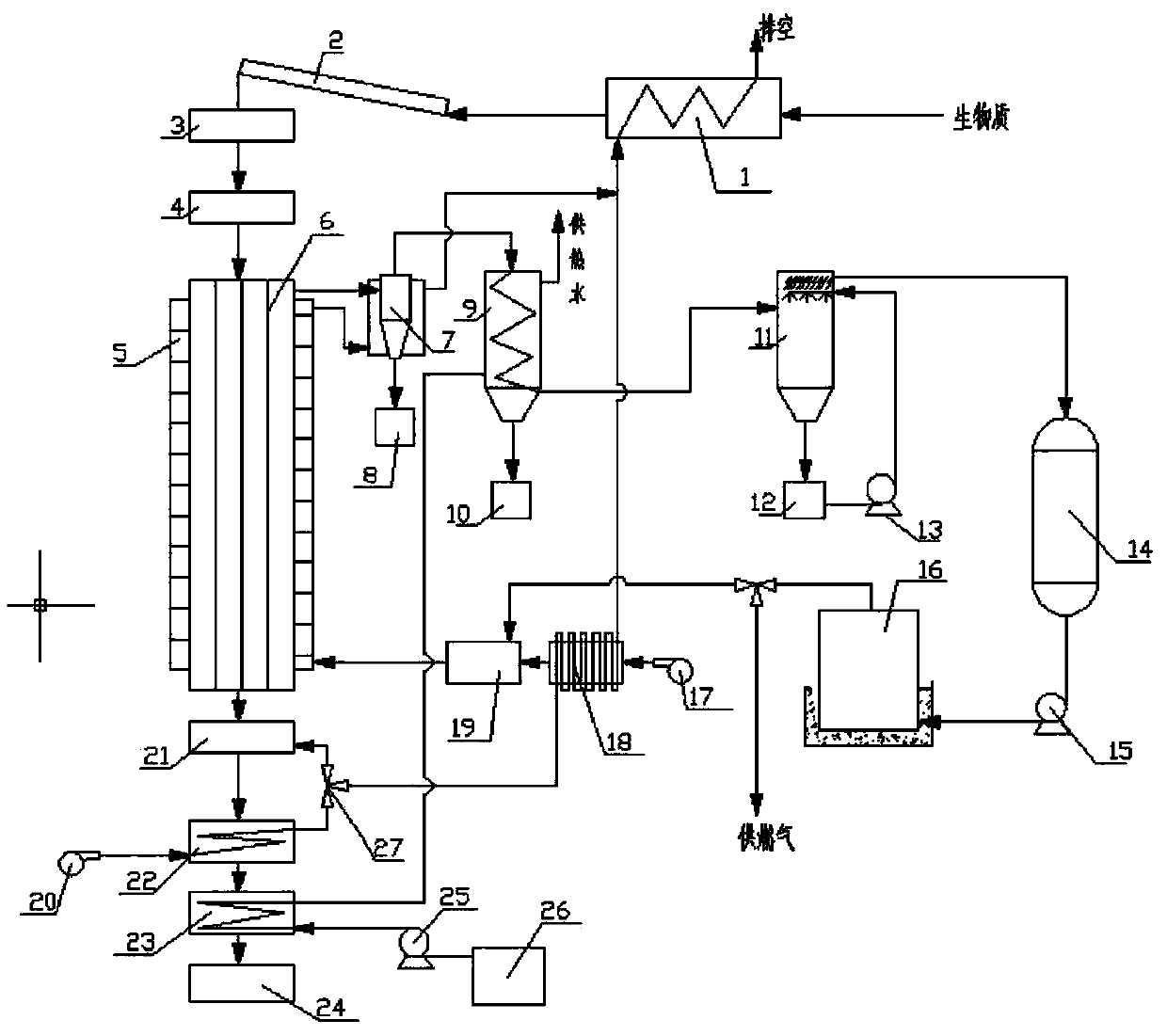

[0027] The continuous biomass moving bed pyrolysis polygeneration system of the present invention includes a pyrolysis unit, a condensation unit, a purification unit, a gas storage unit and a heating unit, the pyrolysis unit is respectively connected to the condensation unit and the heating unit, and the gas storage unit is connected to the purification unit respectively unit and heating unit, the condensing unit is connected to the gas storage unit through the purification unit; the heating unit generates heat, and the pyrolysis unit absorbs heat to convert biomass into charcoal, gas and oil products and separate and store coke; The bio-oil and gas are separated and the bio-oil is stored, the purification unit removes the impurities in the gas, and the gas storage unit stores the gas after the impurities are removed.

[0028] figure 1 A schematic diagram of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com