Manufacturing method for coating silicon rubber/liquid crystal cross linking membrane on bi-component hollow fiber

A manufacturing method and technology of silicone rubber, applied in the field of biomedical engineering, can solve problems such as practical application limitations and restrictions, and achieve the effects of optimizing process conditions, improving integrity and uniformity, and shortening curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

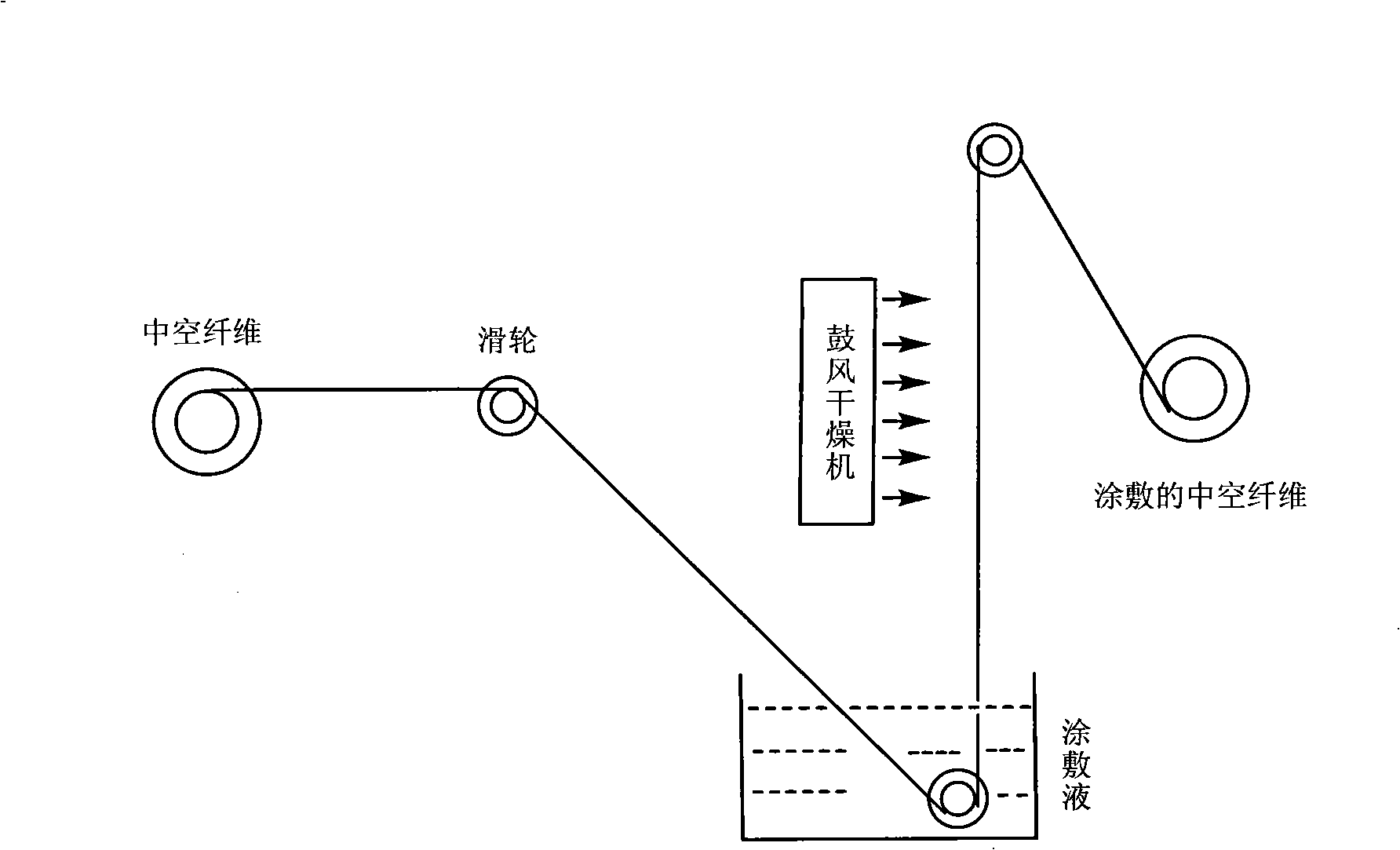

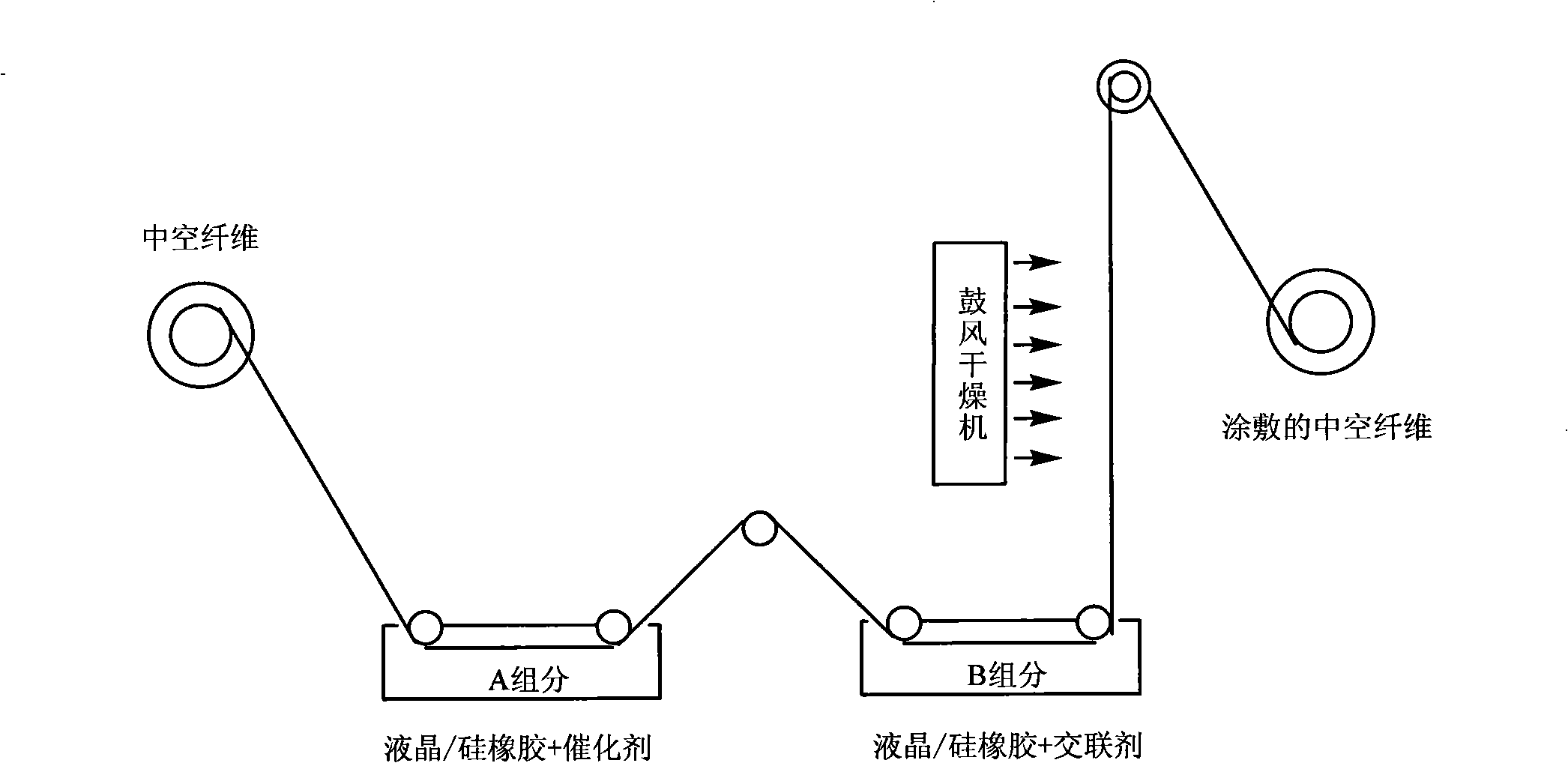

Method used

Image

Examples

Embodiment 1

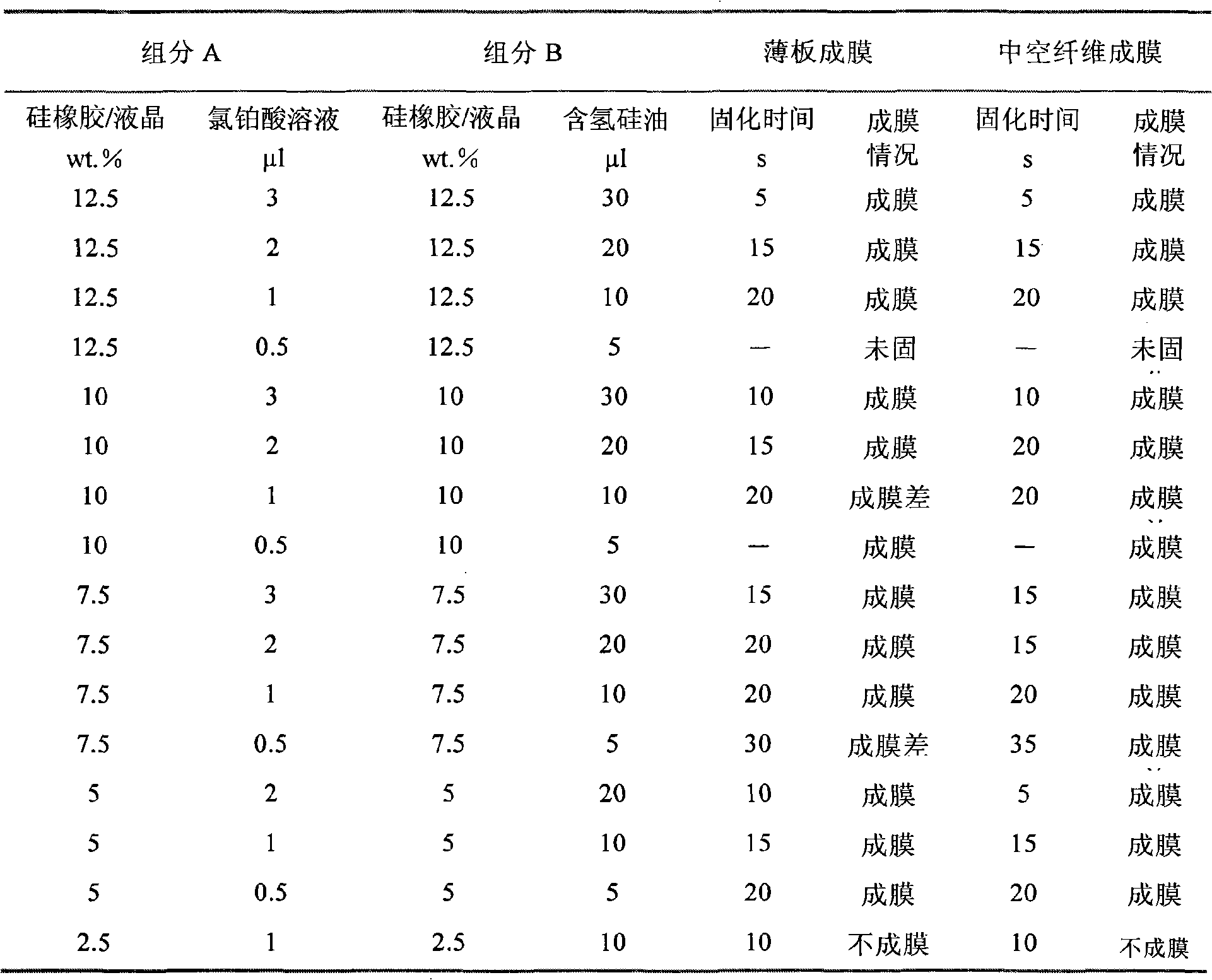

[0021] Embodiment 1 Coating liquid concentration is to the influence experiment of film formation

[0022] Dissolving silicone rubber and cholesteryl acrylate liquid crystals with a vinyl molar mass content of 5% to 10% in tetrahydrofuran to form homogeneous solutions with concentrations of 2.5%, 5.0%, 7.5%, 10.0% and 12.5%, respectively, Add catalyst chloroplatinic acid solution, stir evenly to prepare component A of series concentration; in the tetrahydrofuran (THF) of silicon rubber and cholesteryl enoate liquid crystal which are respectively 2.5%, 5.0%, 7.5%, 10.0% and 12.5% of the same above-mentioned concentration Add a crosslinking agent hydrogen-containing silicone oil into the solution, stir evenly to prepare component B with a series concentration. After dipping the thin plate and polyethersulfone hollow fiber through the solution of component A and component B respectively, the dipping time is 5s; then pass the thin plate and polyethersulfone hollow fiber through ...

Embodiment 2

[0027] Embodiment 2 Curing temperature is to the influence experiment of film formation

[0028] Dissolve silicone rubber and cholesteryl enoate liquid crystals with a vinyl molar mass content of 5% to 10% in tetrahydrofuran to form a uniform solution with a concentration of 5.0% by weight, add catalyst chloroplatinic acid solution, and stir evenly Prepare component A with a series of concentrations; add hydrogen-containing silicone oil cross-linking agent to the same THF homogeneous solution of silicone rubber and cholesteryl enoate liquid crystal with the above-mentioned concentration of 5.0% by weight, and stir evenly to form a series concentration of component B. After impregnating the polypropylene hollow fiber successively through the component A and component B solutions, the silicone rubber is cross-linked and cured by a heating device to obtain a hollow fiber composite membrane whose surface is coated with a uniform silicone rubber / liquid crystal cross-linked membrane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com