Process for producing stibium-free environment-friendly polyethylene terephthalate for bottle

A technology of polyethylene terephthalate and purified terephthalic acid, which is applied in the field of preparation of antimony-free environment-friendly polyethylene terephthalate for bottles, can solve the limitations of the application of antimony-based catalysts, increase Spinning component pressure, can not reach the viscosity and other problems, to achieve the effect of strong rigidity, improve product quality and reduce raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

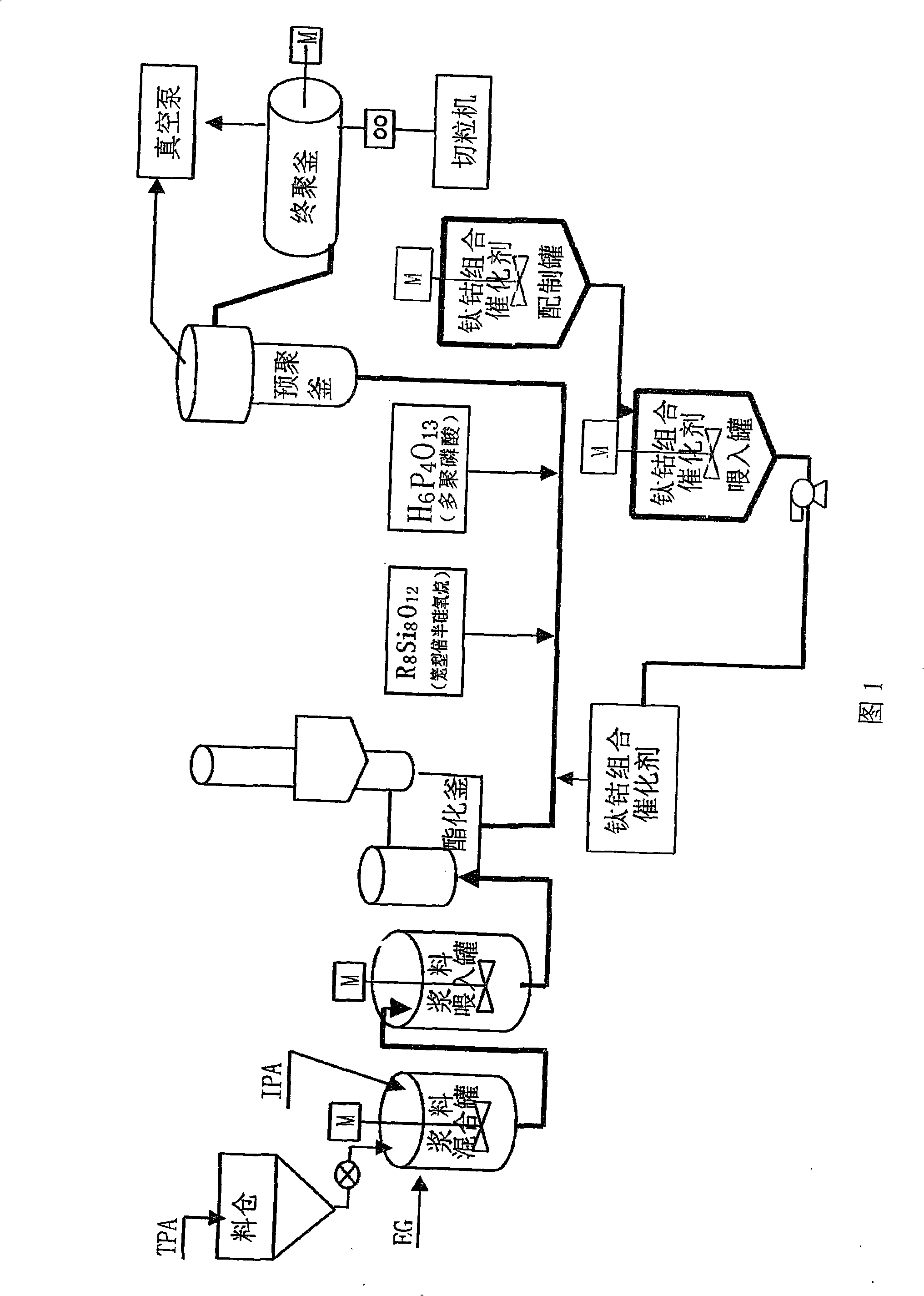

[0020] Referring to Fig. 1, the present invention relates to a kind of preparation method of antimony-free environment-friendly polyethylene terephthalate for bottle, and its technological process is:

[0021] Purified terephthalic acid and ethylene glycol are stirred in the slurry mixing tank according to the set molar ratio (1:1~2.2) to make slurry, which is pumped into the slurry feeding tank, and the slurry is fed to the The slurry enters the esterification tank through the slurry injection nozzle. Under the circulation of the thermosiphon or the action of the agitator, the slurry is uniformly mixed and reacted, and the esterification generates oligomers. The esterified oligomers are combined with the The additives on the pipeline from the oligomer to the prepolymerization kettle are injected into the prepolymerization kettle.

[0022] Additives on the pipeline include catalysts, stabilizers and dispersants.

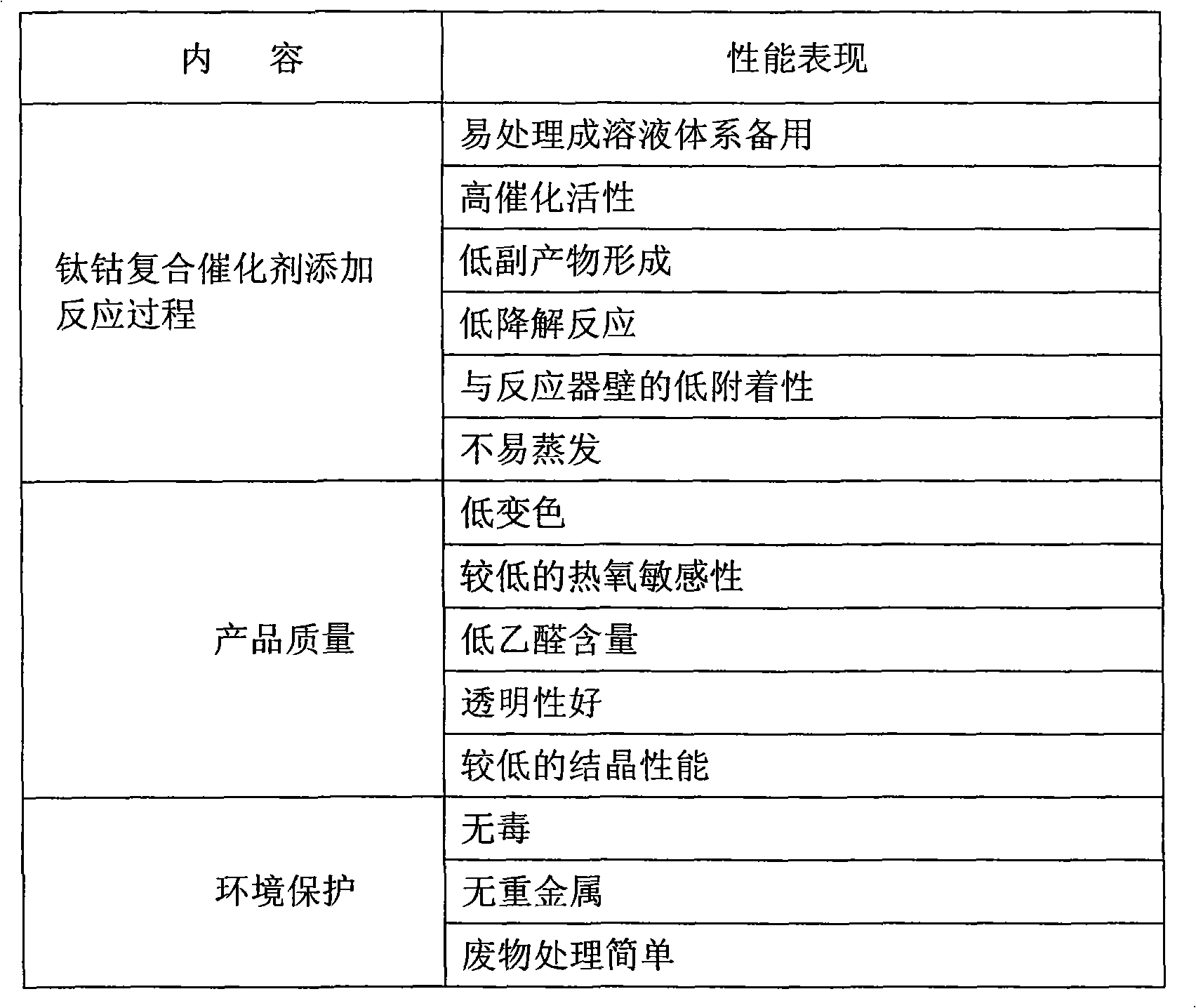

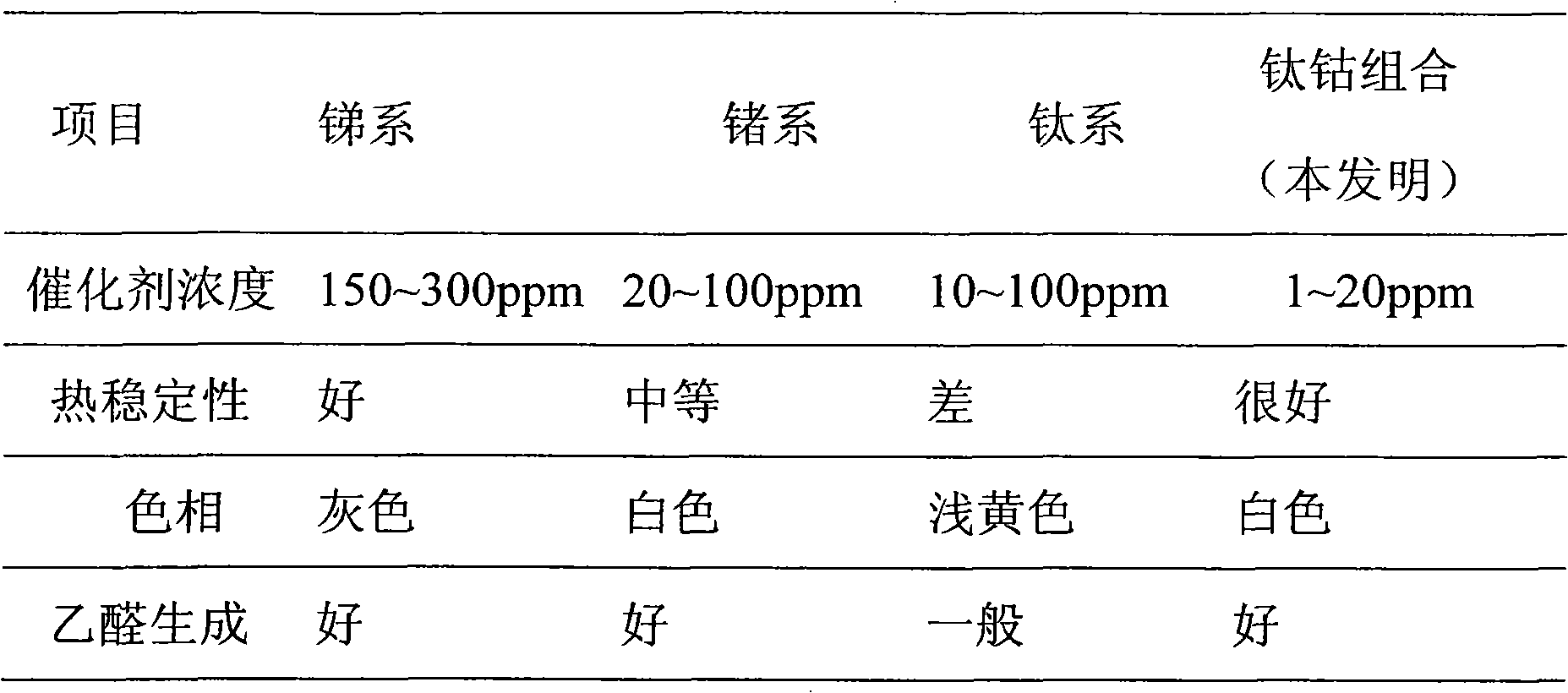

[0023] The catalyst adopts a titanium-cobalt composite catalys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com