Method for extracting rare earth from oxidized neodymium iron boron waste

A neodymium iron boron and rare earth chloride technology, applied in the field of rare earth resource recovery and recycling, can solve the problems of low recycling rate, large amount of liquid waste, low quality of rare earth products, etc., and achieves reduced labor intensity and operation cycle. The effect of shortening, efficiency and productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

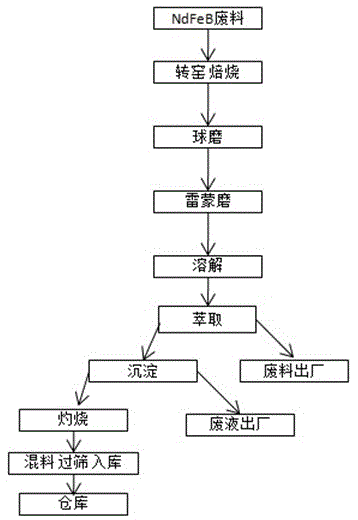

[0034] Such as figure 1 A method for extracting rare earths from oxidized NdFeB waste is shown. The steps are as follows: 1) Ball milling: mix the NdFeB waste with water and perform ball milling, and strictly control the particle size of the mud produced after ball milling , the particle size range is 90-200 mesh; its purpose is to increase the degree of oxidation of ferrous salts and improve the recovery efficiency of rare earths. During the ball milling, the ratio of waste material to water is controlled at 2:3, and the positive and negative error does not exceed 10%; the purpose is to improve the efficiency of ball milling, help to control the particle size of materials, and increase the degree of oxidation of ferrous salt and improve recovery. efficiency. The water used for ball milling is deionized pure water, the purpose of which is to reduce non-rare earth impurities in the product, such as Ca 2+ ,Mg 2+ , Si, Mn, B - etc., so that the content of non-rare earth impur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com