Printing film-laminated metal plate and production method thereof

A production method and metal plate technology, applied in the field of materials, can solve the problems of chemical substances, low printing resistance, poor printing quality, etc., and achieve the effect of improving safety quality, meeting continuous production, and increasing printing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

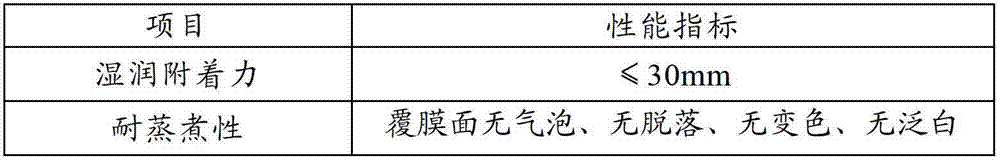

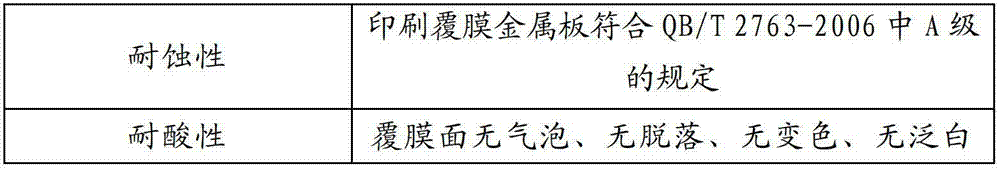

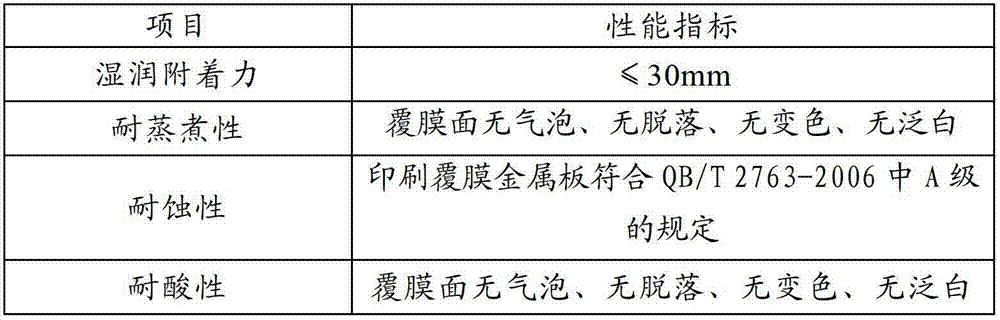

Embodiment 1

[0036] This embodiment provides a printed film-coated metal plate, a printed composite film made of a PET film with a gravure printing pattern and a PET film modified by isophthalic acid, and a metal substrate through an airless The adhesive is formed by hot bonding, and the PET film on the outer layer of the film-coated metal plate has a printed pattern (the "pattern" in the present invention should be understood as various design graphics and text content) on one side and isophthalic Diformic acid modified PET film is attached, and the side attached to the metal substrate is isophthalic acid modified PET film. The present invention is called printed composite film; the inner layer of PET film is not printed. Light film (transparent or opaque film can be selected according to requirements), this invention is called inner film. In this embodiment, both the inner and outer gravure printing films use PET films with a thickness of 15 μm, the metal substrate is a chrome-plated steel...

Embodiment 2

[0052] This embodiment provides a printed film-coated metal plate, including a printed composite film made by dry-compositing a PP film with a gravure printing pattern and a PET film modified with isophthalic acid, and a PP film with a gravure printing and The metal substrate is formed by thermal lamination without adhesive, and the PP film on the outer layer of the coated metal plate has a printed pattern on one side (the "pattern" mentioned in the present invention should be understood as various design graphics and text content) It is bonded to the PET film modified by isophthalic acid, and the side bonded to the metal substrate is the PET film modified by isophthalic acid. The present invention is called a printed composite film; the inner layer is made of gravure printing The side of the PP film with the printed pattern is bonded to the metal substrate, which is called the inner film in the present invention. In this embodiment, both the inner layer gravure printing film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com