Alignment method of maskless laser direct writing lithography device during sheet-to-roll producing

A technology of laser direct writing and lithography equipment, used in microlithography exposure equipment, opto-mechanical equipment, optics, etc., can solve problems such as overshoot and production interruption, and achieve the effect of saving time and enhancing the ability of information transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

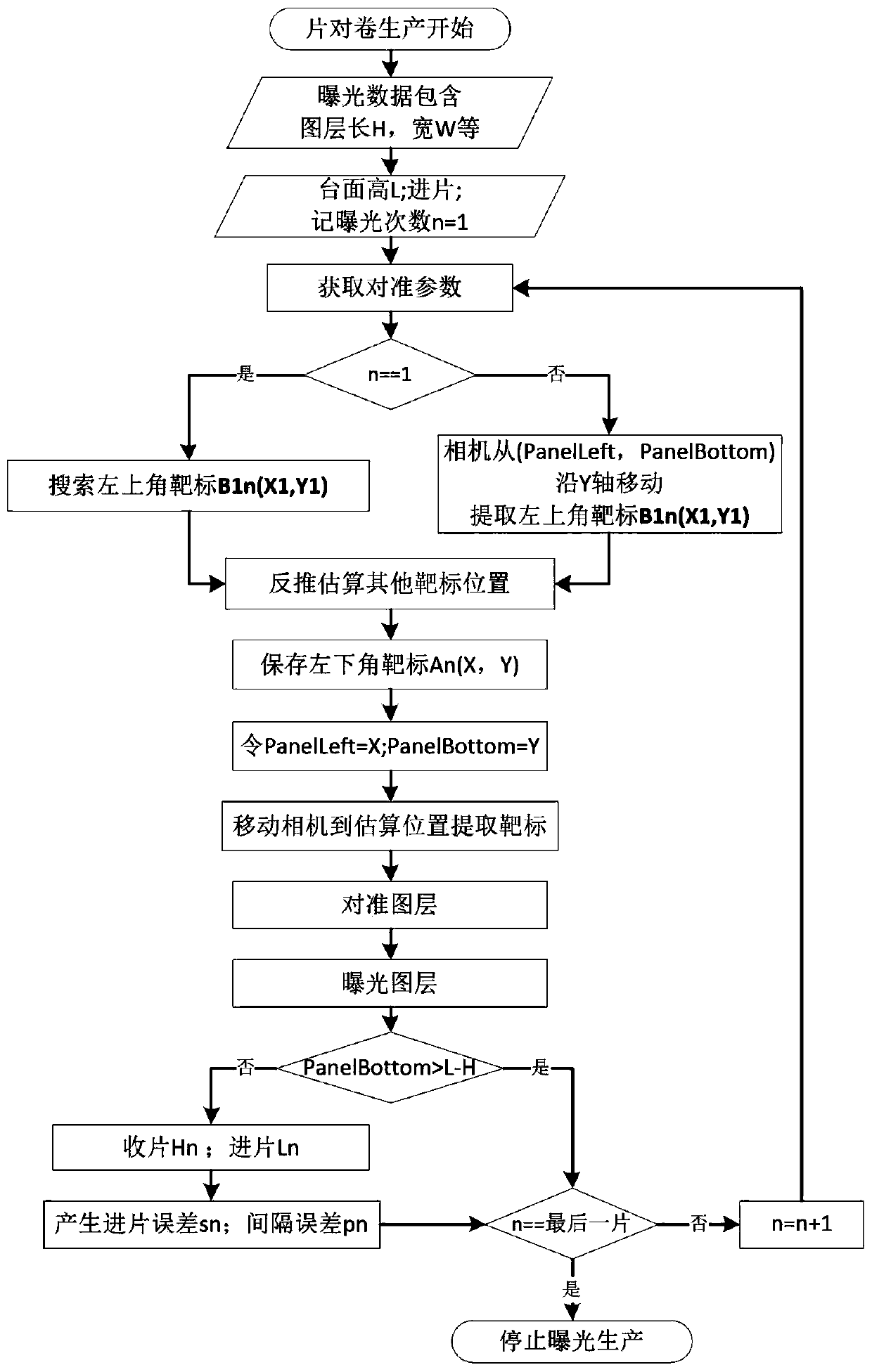

[0030] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

[0031] Such as figure 1 As shown, the alignment method of the maskless laser direct writing lithography device in the embodiment of the present invention when producing sheet-to-roll, based on the roll-to-roll maskless laser direct writing lithography device, includes the following steps:

[0032] In the sheet-to-roll production mode, the alignment starts after automatically searching for the alignment target;

[0033] Using the alignment result of the last piece, calculate the accumulative board-in error, automatically correct the alignment parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com