Automatic production device for stator piece and rotor piece

A technology for producing devices and stators and rotors, which is applied to positioning devices, manufacturing stator/rotor bodies, feeding devices, etc., can solve problems such as the inability of mass production to meet the requirements, the large difference between the stator and rotor pieces and the standard pieces, and the consumption of human resources. Achieve the effect of satisfying large-scale continuous production, realizing automatic operation and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

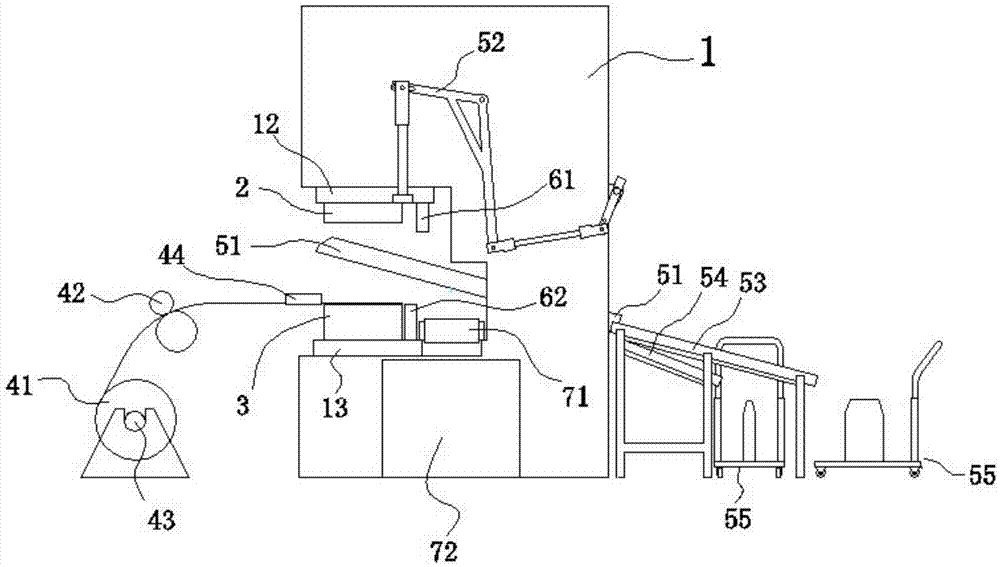

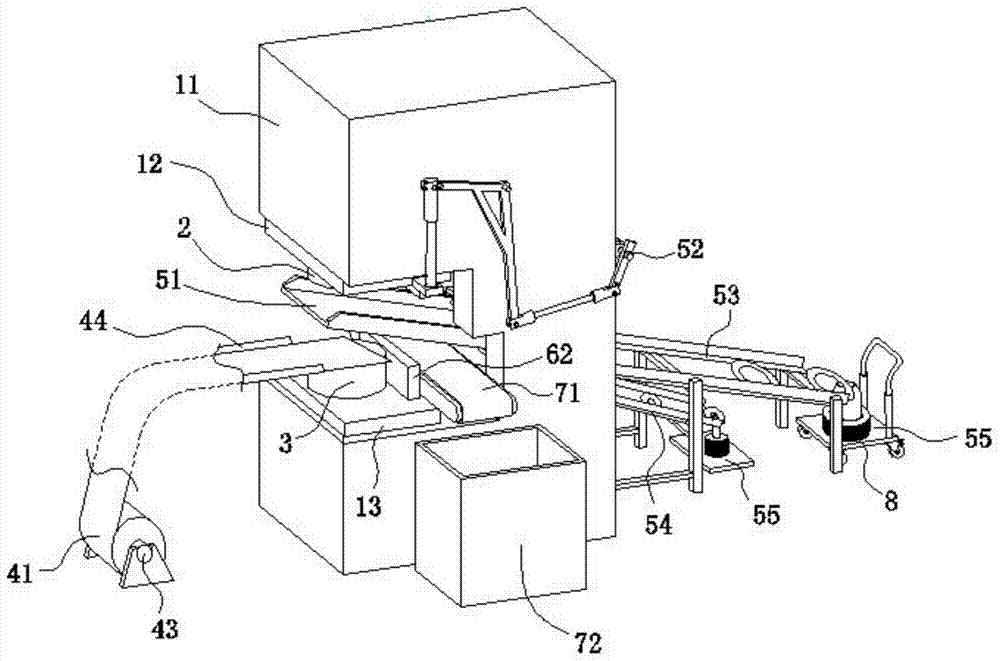

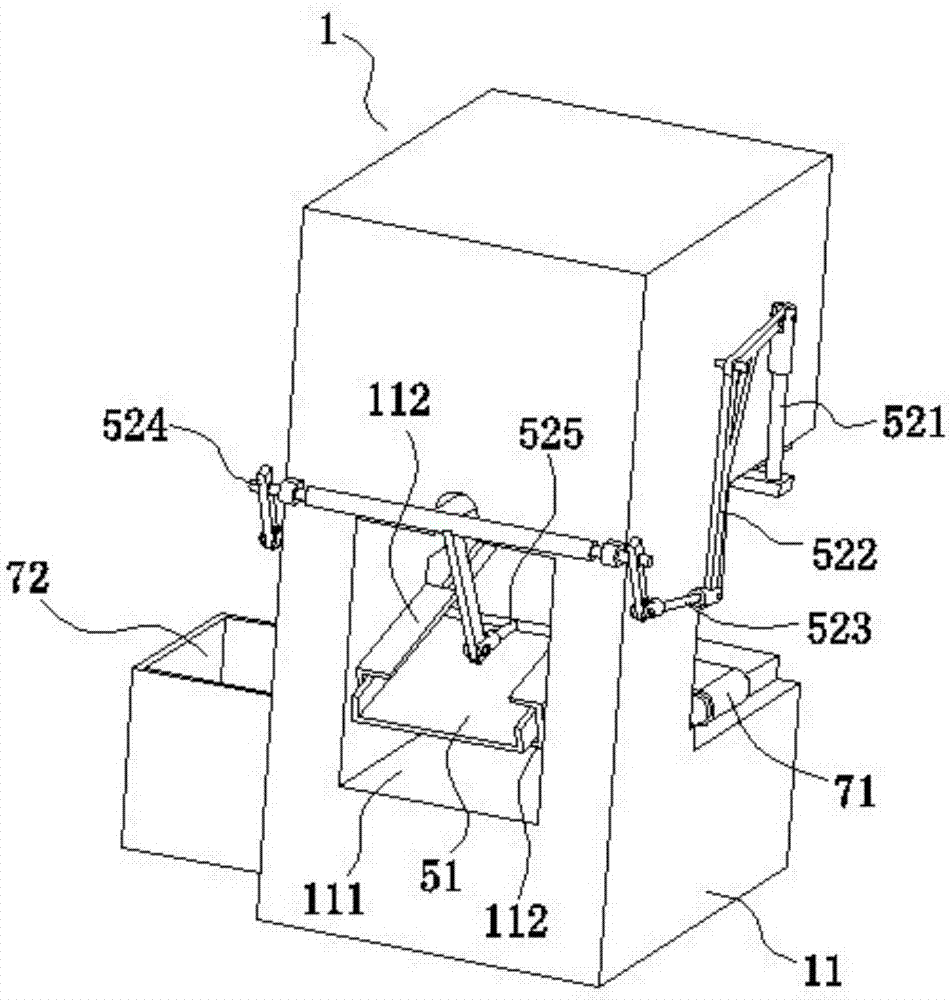

[0021] Such as Figure 1 to Figure 2 As shown, an automatic production device for stator and rotor pieces includes a punching machine 1, a control system, an upper mold 2, a lower mold 3, an air suction device, a feeding device, a finished product receiving device 5, a waste material cutter and a waste material receiving device. The punch press 1 is provided with a bed frame 11, an upper die base 12, a lower die base 13 and a drive unit for driving the upper die base 12 to move downward, and the upper die base 12, the lower die base 13 and the drive unit are located at the front end of the bed frame 11, Upper mold 2 and lower mold 3 are fixedly installed on upper mold base 12 and lower mold base 13 respectively, upper mold 2 is provided with suction holes, and the suction device is connected with upper mold 2 through the suction holes. The feeding device is arranged in front of the punching machine 1, and the feeding device is provided with a material roll 41, a reel 43 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com