Longitudinal roller rolling forming equipment and method for metal polar plate flowing channels of fuel cell

A metal plate and fuel cell technology, applied in the field of fuel cells, can solve the problems of prominent springback and cracking, and achieve the effect of avoiding cracking, reducing springback and satisfying continuous production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention more clear, the embodiments of the present invention are described in detail as follows in conjunction with the accompanying drawings.

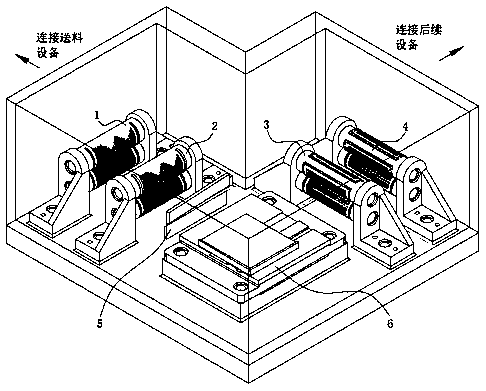

[0025] Such as figure 1 As shown, the fuel cell metal plate runner longitudinal roll forming equipment proposed by the present invention includes a linear runner longitudinal roll preforming device 1, a linear runner longitudinal roll secondary forming device 2, and a U-shaped runner longitudinal roll forming device 2. Roll preforming device 3 , U-shaped channel longitudinal rolling secondary forming device 4 , plate shearing device 5 , and plate transfer device 6 .

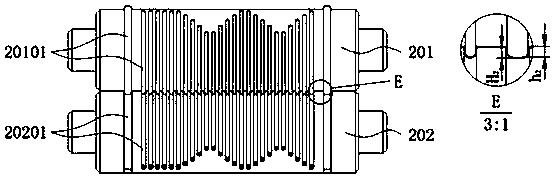

[0026] Wherein, the linear runner longitudinal rolling preforming device 1 comprises a linear runner longitudinal rolling preforming punch 101 and a linear runner longitudinal rolling preforming die 102, such as image 3 As shown, the two turn in opposite directions; the linear runner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com