Microwave composite dielectric substrate for high-frequency and high-speed environment and preparation method of dielectric substrate

A composite medium, microwave technology, applied in chemical instruments and methods, applications, household appliances, etc., can solve the high cost of hollow/mesoporous silica microspheres, difficult mass production, and the yield of hollow/mesoporous silica microspheres Low thermal expansion, low cost and low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A microwave composite dielectric substrate used in a high-frequency and high-speed environment, the preparation method of which is as follows:

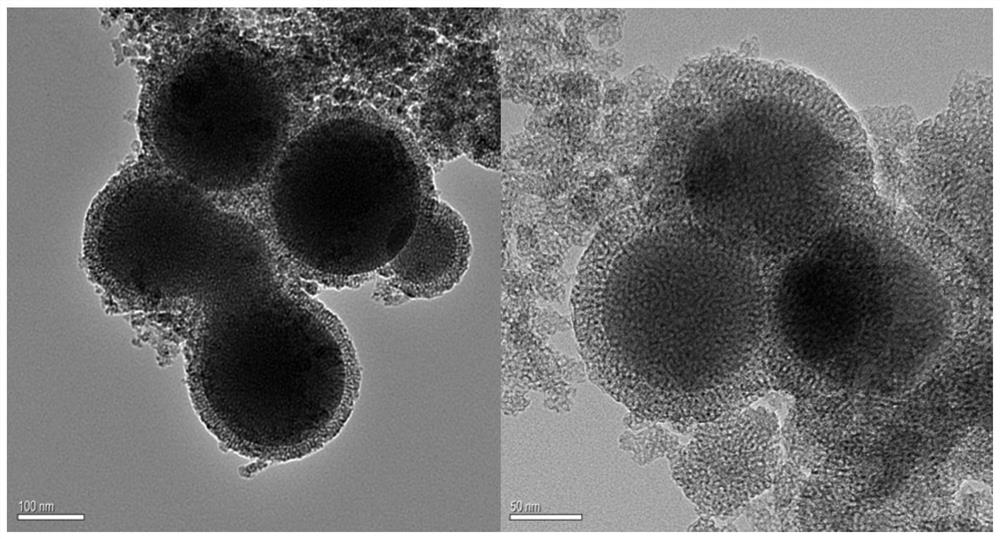

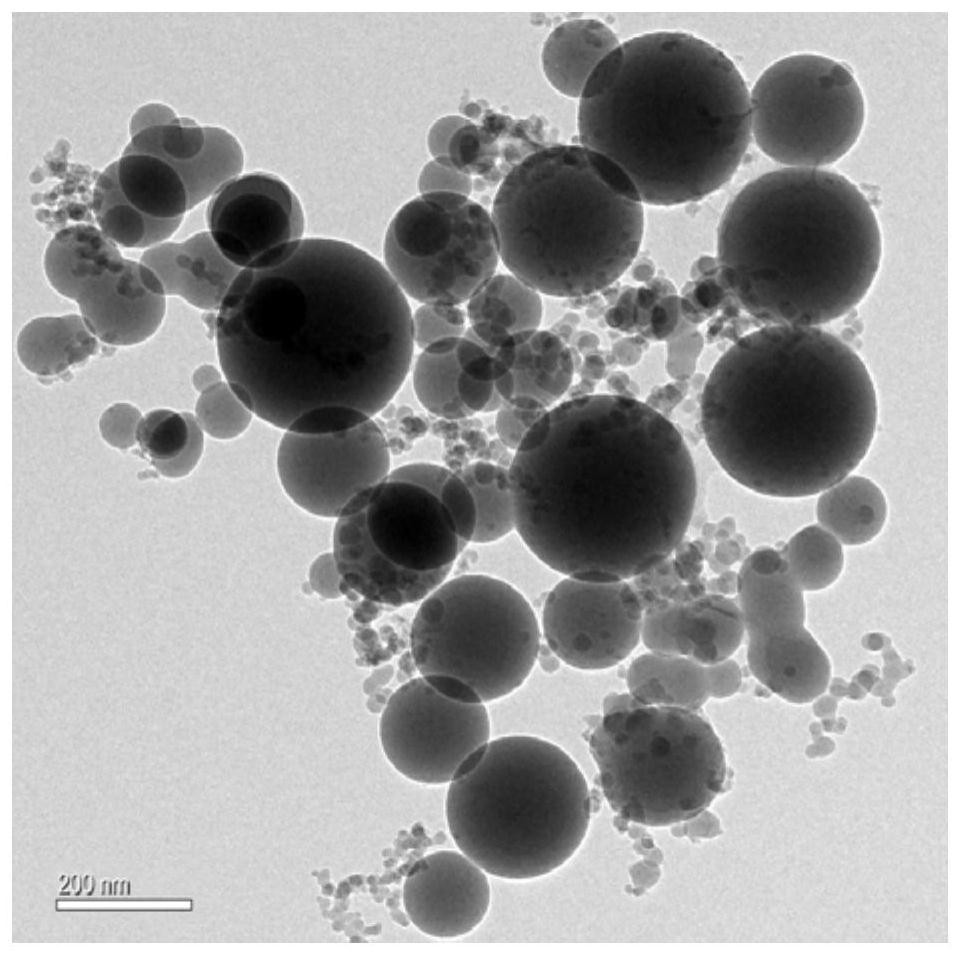

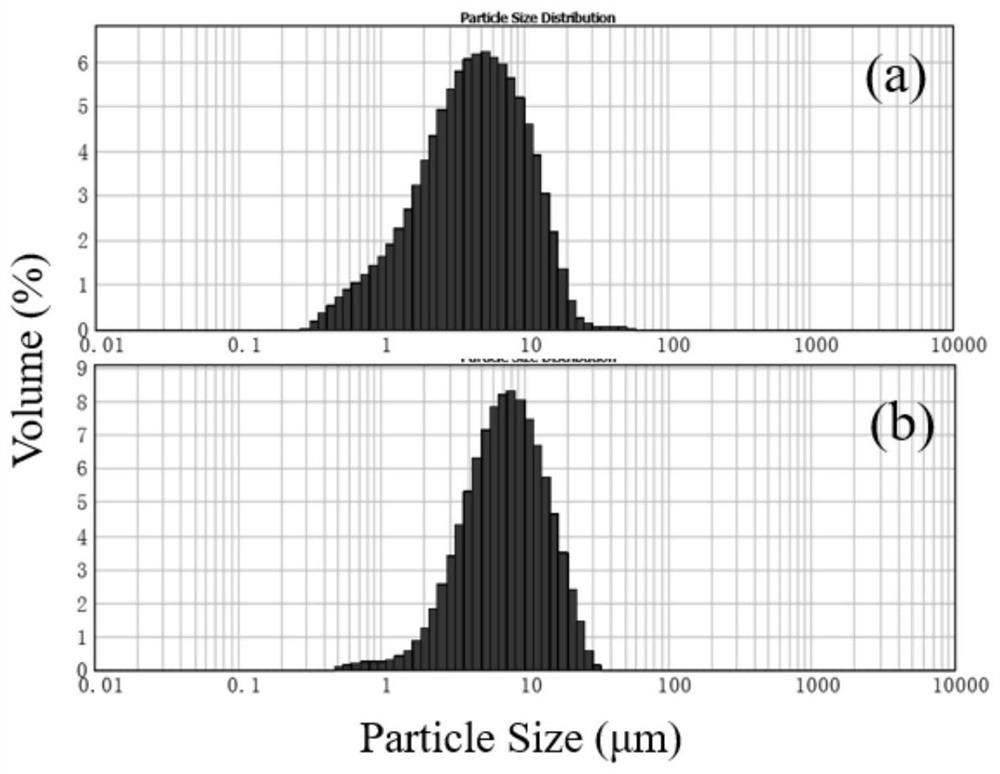

[0042] (1) Disperse the nano-silica powder in deionized water, adjust the pH to 11 with ammonia water and stir, add a surfactant in the stirring process, and the surfactant is cetyltrimethylammonium bromide, at room temperature Stir for 1 hour, at this time fully disperse tetraethyl orthosilicate in ethanol, add dropwise to the above solution twice, add dropwise while stirring, and continue to react for 5 hours after the dropwise addition of tetraethyl orthosilicate is completed , deionized water and ethanol were centrifuged and washed several times, and the white precipitate was dried at 70 °C for 8 hours and then ground for use;

[0043] (2) Put the above-mentioned white powder in a crucible, and use a muffle furnace to perform high-temperature treatment to remove the template agent. The reaction temperature of the high-tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com