Method for preparing corundum microporous aerator pipe

A microporous aeration and corundum technology is applied in the field of preparation of corundum microporous aeration pipes, which can solve the problems of energy consumption, easy blockage, fracture and deformation of the pipe body, etc., and achieves energy saving, high initial strength, and improved service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

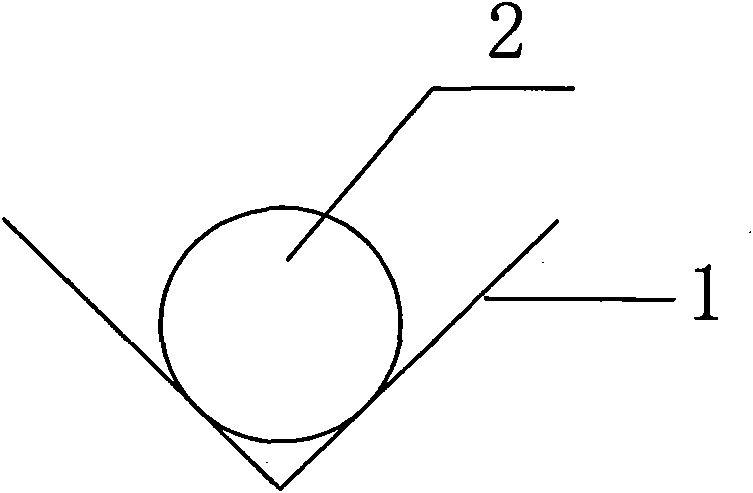

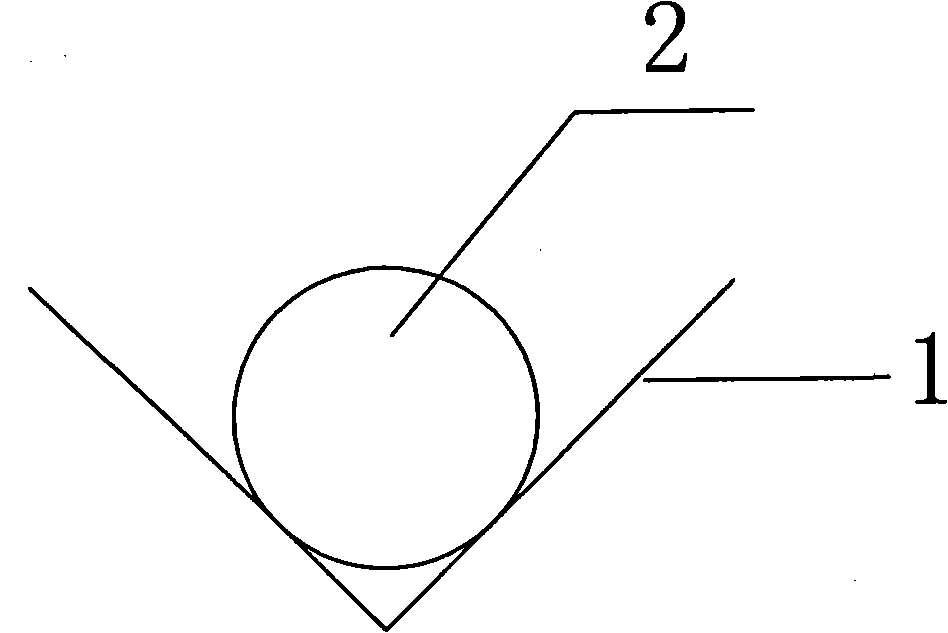

[0022] 83 parts by weight of corundum sand with a particle size of 80 meshes, 14 parts by weight of kaolin, 0.5 parts by weight of binder dextrin, 2.5 parts by weight of porogen wood powder, 0.05 parts by weight of crosslinking agent N-methylolacrylamide and 18 parts by weight of water Parts by weight, according to the conventional process, mix, mature, and extrude to form a corundum tube of DN70×1000mm with a wall thickness of 10mm, solidify and dry on a V-shaped support, and then sinter in a pusher kiln with a high temperature zone of 1200-300°C and a length of 40 meters. Into the corundum microporous aeration tube. The porosity of the product is 45.6%, the compressive strength is 56MPa, the bending strength is 25MPa, and the roundness is 0.4.

Embodiment 2

[0024] 82.5 parts by weight of corundum sand with a particle size of 100 meshes, 14 parts by weight of kaolin, 0.5 parts by weight of polyvinyl alcohol as a binder, 3 parts by weight of porogen coke powder, 0.1 parts by weight of crosslinking agent N-methylolacrylamide and water 25 parts by weight, mixed, matured and extruded according to the conventional process to form a DN70×1200mm corundum tube with a wall thickness of 15mm, cured on a V-shaped support and dried in a pusher kiln with a high temperature zone of 1200-300°C and a length of 50 meters Sintered into corundum microporous aeration tube. The porosity of the product is 47.3%, the compressive strength is 50MPa, the bending strength is 28MPa, and the roundness is 0.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com