Baking-free no-methanal coating dyeing nano adhesive water-based latex

A technology of paint dyeing and water-based latex, which is applied in dyeing, textiles and papermaking, etc. It can solve the problems of continuous production of paint dyeing, production waste, and easy adhesion that affect the shear resistance stability, and achieve improved shear resistance. , It is not easy to stick to the roll, and the effect is soft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

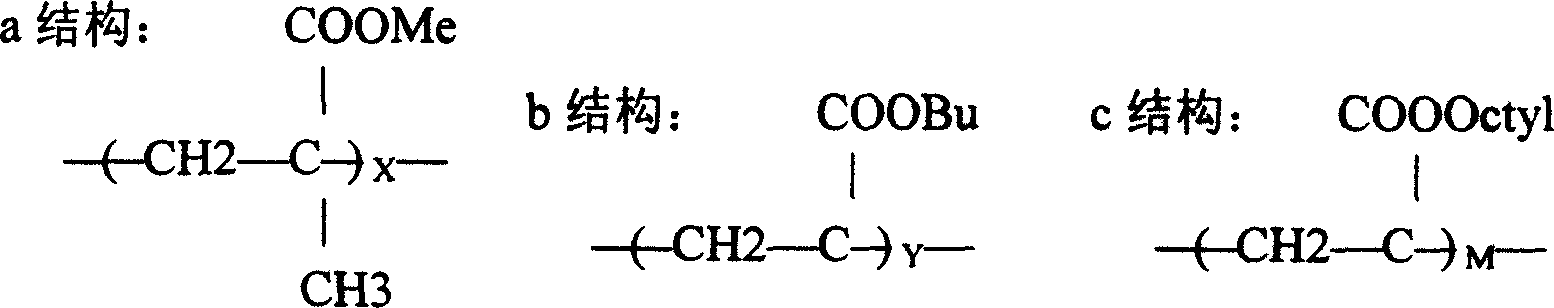

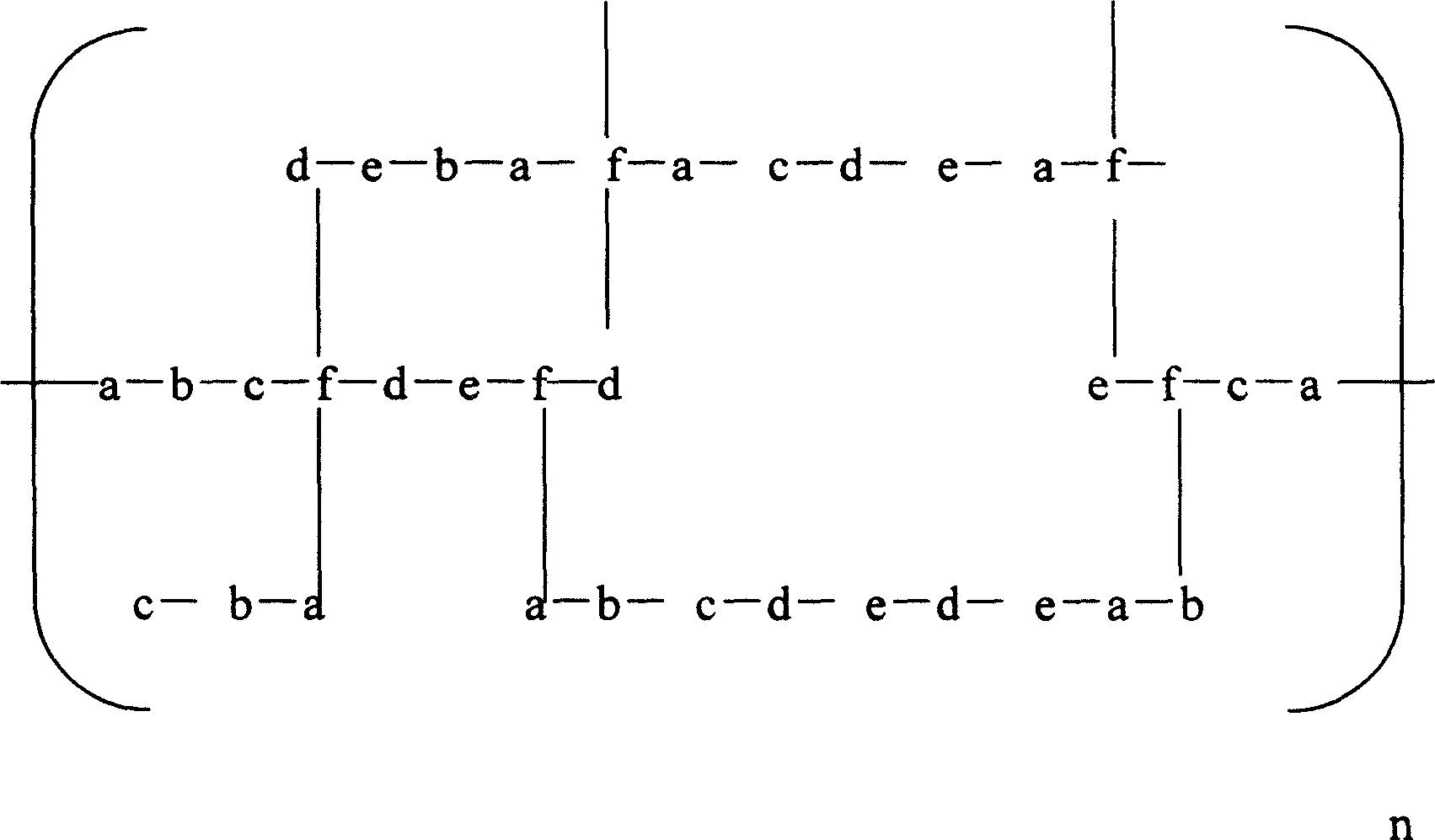

[0040] The application examples given below can synthesize the adhesive described in this patent, and the application effect of the adhesive synthesized according to the formula in Table 1 is listed in Example 8.

[0041] Will be equipped with a stirrer, reflux condenser. Place the three-necked flask of the dropping funnel on a constant temperature water bath, add emulsifier and distilled water, stir, heat up to 78-80°C, add initiator, stir for 0.1 hour, add soft / hard monomer, hydrophilic monomer and For the pre-crosslinking monomer monomer, keep warm for 0.5 hours after the dropwise addition, then raise the temperature to about 85°C, keep warm for 1 hour, cool down, neutralize with alkali (ammonia water is recommended), filter, and discharge.

[0042] The synthesized adhesive has a particle diameter of about 100nm, is concentrated in distribution, and has excellent shear stability, acid and alkali resistance, electrolyte resistance and dilution resistance.

[0043] co...

Embodiment 2

[0046] The preparation method is the same as in Example 1.

[0047] composition

Embodiment 3

[0049] The preparation method is the same as in Example 1.

[0050] composition

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com