Gas drilling underground motor drilling tool

A technology for gas drilling and power drilling tools, which is applied to drilling driving devices, drilling equipment, earth-moving drilling, etc. and speed instability, to achieve the effect of convenient maintenance and matching, avoiding energy loss, and strong interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

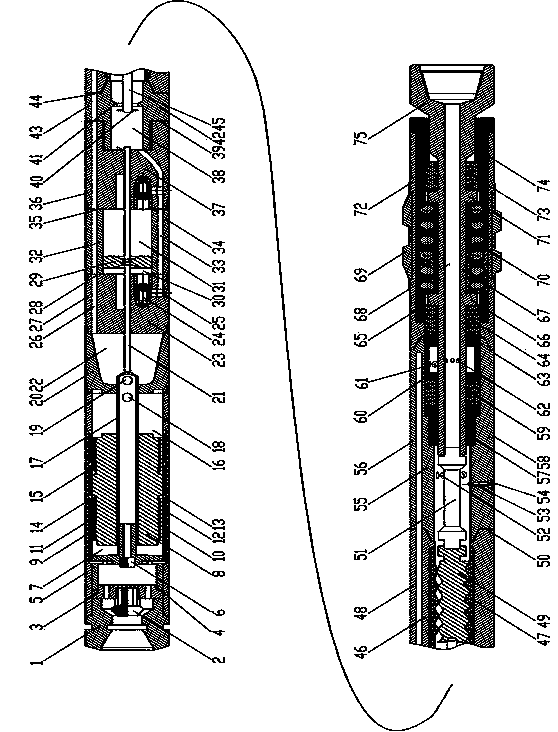

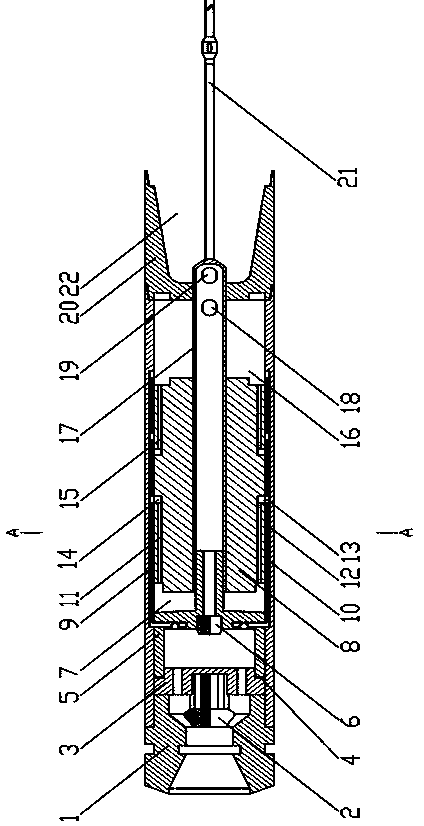

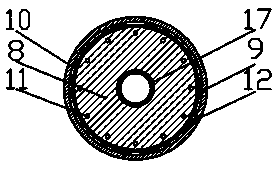

[0044] Referring to the accompanying drawings in the specification, the present invention discloses a double-acting pneumatic short joint, which includes an upper joint 1, a check valve 2, a valve seat 3, a gasket a4, a flow plate 5, a diverter plug 6, a pneumatic piston 8, an outer cylinder 9. Inner cylinder 10, gas distribution cylinder 17, exhaust joint 20 and connecting rod 21. One end of the upper joint 1 is threadedly connected with the drilling tool assembly, and the other end is threaded with the outer cylinder 9; the valve seat 3 is positioned on the lower end of the upper joint 1 and the upper end of the distribution plate 5 through steps; the center hole of the valve seat 3 is equipped with a check valve 2, The gasket a4 is set between the valve seat 3 and the distribution plate 5; the distribution plate 5 is positioned inside the outer cylinder 9 through keys, and the diverter plug 6 is installed on the center hole of the distribution plate 5; several axial air chan...

Embodiment 2

[0047] With reference to the drawings in the description, the present invention discloses a double-acting hydraulic power nipple, including a top cover 23, an oil cylinder 32, an oil cylinder shell 34, a bottom cover 37, a rectangular one-way valve 24, a plug 25, a hydraulic plunger 29, a rib Plate 81, gasket b28 and gasket c35. The double-acting hydraulic power nipple is provided with three passages in the circumferential direction: the exhaust chamber 26, the pump oil chamber 33 and the oil return chamber 76; the exhaust chamber 26 consists of the top cover 23, the top cover shell 27, the oil cylinder 32, the oil cylinder shell 34 Bottom cover 37, bottom cover shell 36 and rib plate 81 form, and inlet is communicated with exhaust chamber 22, and outlet is communicated with exhaust cavity 26 of closed cycle liquid drive motor; The cover 37, the bottom cover shell 36 and the rib plate 81 are formed, the inlet is connected to the oil outlet of the front oil chamber pump oil val...

Embodiment 3

[0049] With reference to the drawings in the description, the present invention discloses a closed cycle liquid drive motor, which includes a bearing joint 42, a bearing joint housing 43, an anti-drop lock nut 40, an anti-drop connecting rod 45, a rotor 49, a stator housing 46, and a stator rubber Bushing 47, motor housing 48, cardan shaft assembly 51, cardan shaft assembly housing 55, cardan shaft assembly housing 56, oil return hole 52, oil drain hole 53, oil drain plug 54, gasket e44 and gasket f50. The double-acting hydraulic power nipple is provided with two passages, the exhaust cavity 26 and the oil return cavity 76 in the circumferential direction; the exhaust cavity 26 is composed of a bearing joint 42, a bearing joint housing 43, a stator housing 46, a motor housing 48, and a cardan shaft. The assembly shell 55, the cardan shaft assembly shell 56 and the rib plate 81 are formed, the inlet is connected with the exhaust chamber 26 of the double-acting hydraulic power n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com