Deepwater high-density drilling fluid capable of resisting high temperature of 220 DEG C

A drilling fluid and high-density technology, which is applied in the field of drilling fluid for oil drilling, can solve the problems affecting the rheology and filtration performance of drilling fluid, weakening the anti-pollution ability of the system, and degrading the water solubility of treatment agents, etc., to achieve the purpose of suppressing gas Strong hydrate capacity, good lubricating effect, and low filtration loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

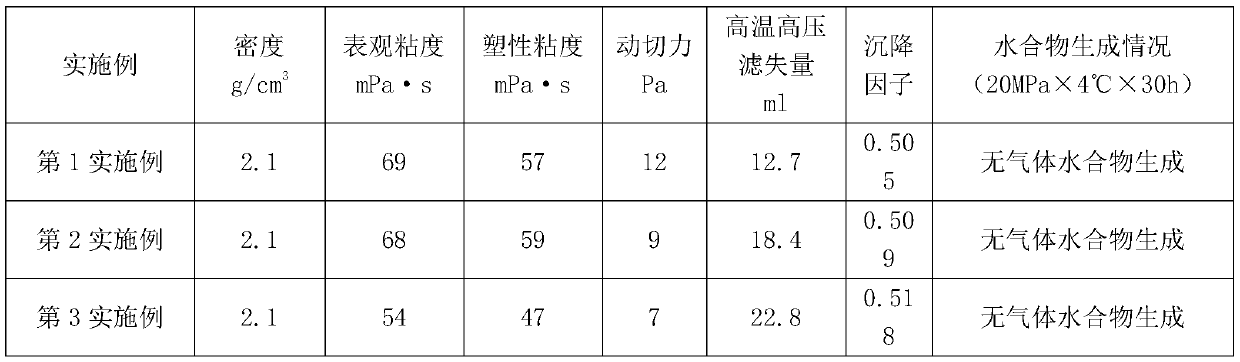

Examples

Embodiment 1

[0029] A deep-water high-density drilling fluid resistant to high temperatures of 220°C includes the following components in mass percentages: 100 parts of seawater; 0.2 parts of soda ash; 0.3 parts of caustic soda; 1.5 parts of bentonite;

[0030] 0.3 parts of flow regulator, the flow regulator is prepared by mixing nano-montmorillonite and lithium magnesium silicate, the ratio of nano-montmorillonite: lithium magnesium silicate is 1:5;

[0031] The thickening and cutting agent is 3.0 parts of temperature-sensitive associative polymer;

[0032] 8.0 parts of anti-high temperature fluid loss reducer, made by mixing sulfonated lignite resin: sulfomethyl phenolic resin, drying at 105°C, and grinding into 200-mesh powder. The ratio of sulfonated lignite resin: sulfonated phenolic resin is 2: 3;

[0033] 4.0 parts of high-temperature anti-collapse agent, one of sulfonated asphalt and emulsified asphalt;

[0034] 15.0 parts of hydrate inhibitors are prepared by mixing thermodynami...

Embodiment 2

[0038] A deep-water high-density drilling fluid resistant to high temperatures of 220°C includes the following components in mass percentages: 100 parts of seawater; 0.2 parts of soda ash; 0.3 parts of caustic soda; 1.5 parts of bentonite;

[0039] 0.3 parts of flow regulator, made by mixing nano-montmorillonite and lithium magnesium silicate, the ratio of nano-montmorillonite: lithium magnesium silicate is 1:5;

[0040] The thickening and cutting agent is 2.5 parts of temperature-sensitive associative polymer;

[0041] 8.0 parts of anti-high temperature fluid loss reducer, made by mixing sulfonated lignite resin: sulfomethyl phenolic resin, drying at 105°C, and grinding into 200-mesh powder. The ratio of sulfonated lignite resin: sulfonated phenolic resin is 2: 3;

[0042] 3.0 parts of high-temperature anti-collapse agent, one of sulfonated asphalt and emulsified asphalt;

[0043] 15.0 parts of hydrate inhibitors are prepared by mixing thermodynamic inhibitors sodium chlori...

Embodiment 3

[0047] A deep-water high-density drilling fluid resistant to 220°C high temperature includes the following components in mass percentage: 100 parts of seawater; 0.2 parts of soda ash; 0.3 parts of caustic soda; 1.5 parts of bentonite; It is prepared by mixing lithium magnesium oxide, and the ratio of nano-montmorillonite: lithium magnesium silicate is 1:5;

[0048] The thickening and cutting agent is 2.0 parts of temperature-sensitive associative polymer;

[0049] 5.0 parts of anti-high temperature fluid loss reducer, made by mixing sulfonated lignite resin: sulfomethyl phenolic resin, drying at 105°C, and grinding into 200 mesh powder. The ratio of sulfonated lignite resin: sulfonated phenolic resin is 2: 3;

[0050] 2.0 parts of high-temperature anti-collapse agent, one of sulfonated asphalt and emulsified asphalt;

[0051] 15.0 parts of hydrate inhibitors are prepared by mixing thermodynamic inhibitors sodium chloride and potassium formate, and the ratio of sodium chlorid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com