Three-hole-site synchronous drilling-type advanced geological drilling device

A drilling device and geology technology, applied in supporting devices, drilling equipment, directional drilling, etc., can solve problems such as affecting the progress of tunnel construction, difficult to ensure drilling quality, and many manpower and material resources, and achieve high practical value and easy front and rear adjustment. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

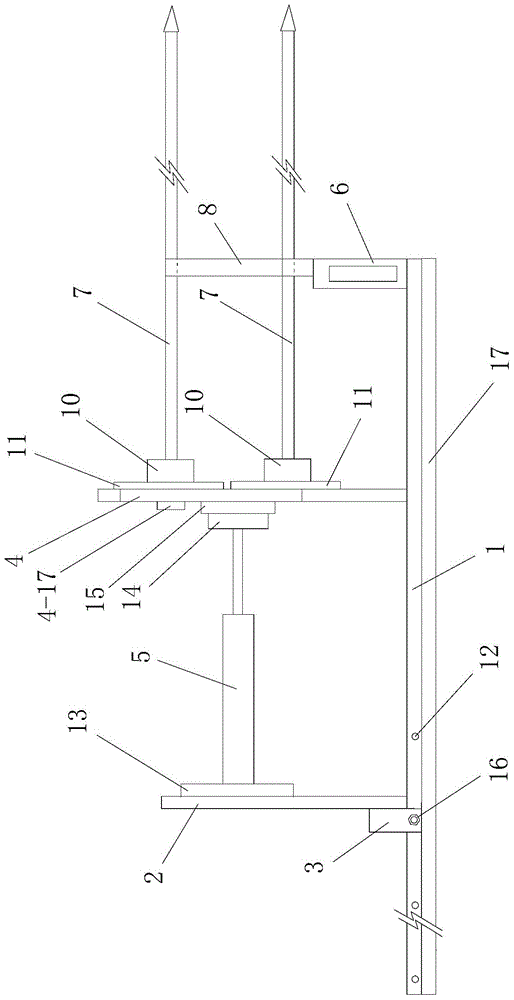

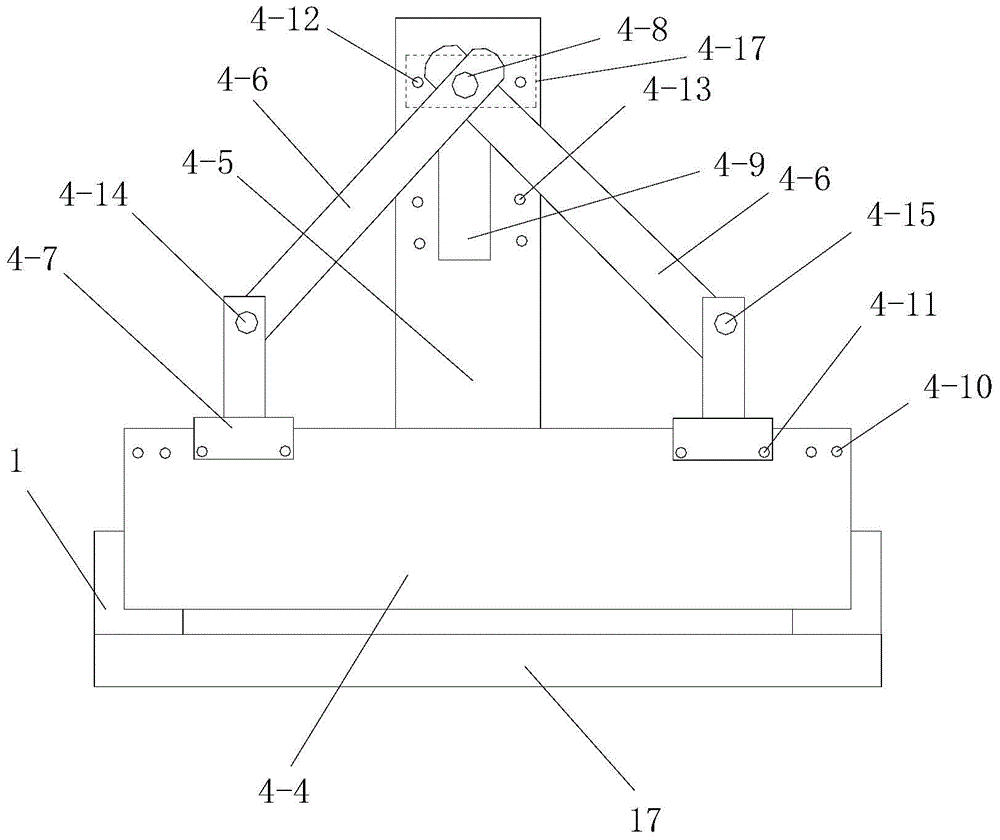

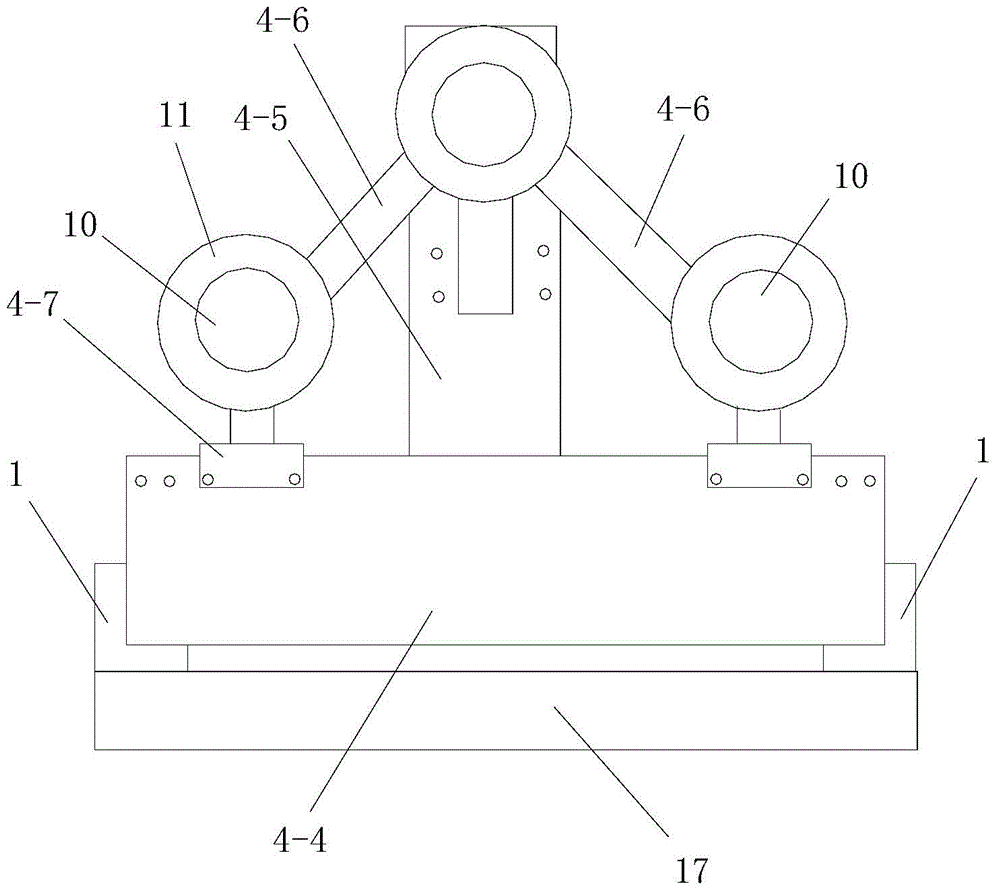

[0035] Such as figure 1 , figure 2 and image 3As shown, the present invention includes a horizontal workbench 17 located at the rear side of the tunnel face under construction, two horizontal steel rails 1 respectively installed on the left and right sides of the upper part of the horizontal workbench 17, and moving back and forth along the two horizontal steel rails 1 The rear push frame 2, the rear limit frame 3 that is clamped on the two horizontal rails 1, the horizontal sliding frame 4 that slides horizontally along the two horizontal rails 1, and promotes the horizontal sliding frame 4 a hydraulic cylinder 5 for horizontal sliding and a front-end support platform 6 positioned at the front ends of the two horizontal rails 1. The hydraulic cylinder 5 is arranged horizontally, the cylinder rear end of the hydraulic cylinder 5 is fixed on the rear push frame 2 and the front end of the piston rod is fixed on the horizontal sliding frame 4; the two horizontal rails 1 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com