Clay-free high temperature resistance reservoir drilling fluid and preparation method thereof

A high temperature resistance and drilling fluid technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of reservoir drilling fluid system performance deterioration, etc., to achieve good settlement stability, excellent shear dilution performance, good Effect of Reservoir Protection Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

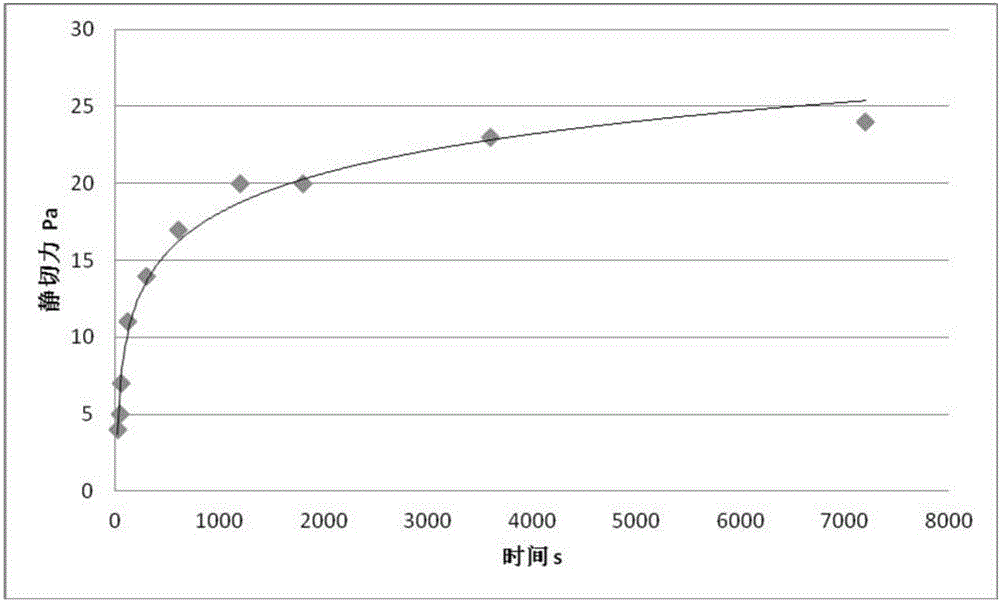

Image

Examples

Embodiment 1

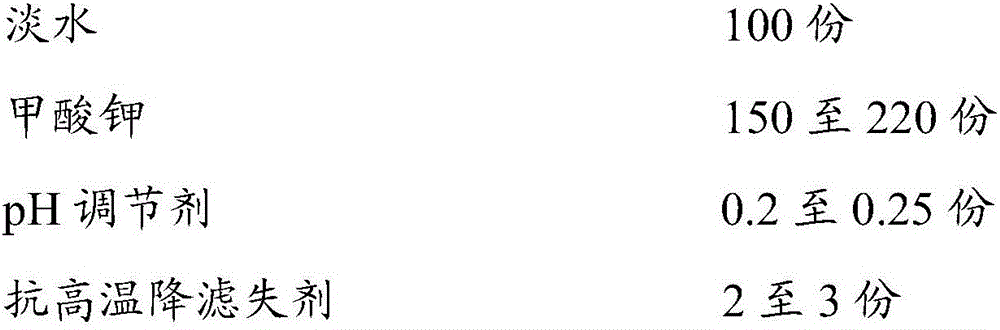

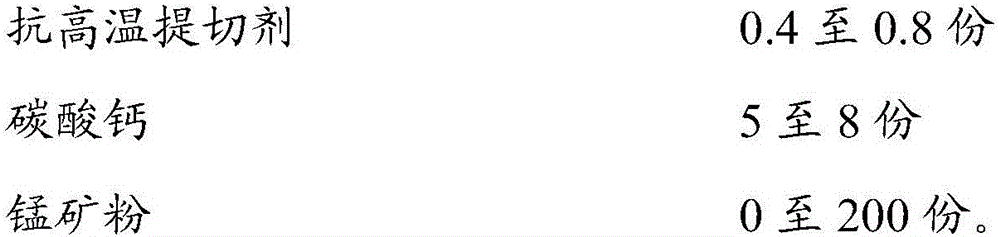

[0044] Fully dissolve 660g of potassium formate in 300mL of fresh water, then slowly add 0.66g of sodium hydroxide, 6.0g of potato cross-linked starch (Beijing Zhongke Risheng Technology Co., Ltd.), 1.6 g xanthan gum (Ordos Zhongxuan Biochemical Co., Ltd.), 24.0g calcium carbonate through particle grading (comprising particle size is 1200 mesh, 800 mesh and 400 mesh calcium carbonate powder, and the weight ratio of the three is 1: 1:1) and 184g manganese ore powder (Norway Elkem, micromax), stirring at high speed for 20min.

Embodiment 2

[0046] Fully dissolve 660g of potassium formate in 300mL of fresh water, then slowly add 0.66g of sodium hydroxide, 6.0g of potato cross-linked starch (Beijing Zhongke Risheng Technology Co., Ltd.), 1.6 g xanthan gum (Ordos Zhongxuan Biochemical Co., Ltd.), 24.0g calcium carbonate through particle grading (comprising particle size is 1200 mesh, 800 mesh and 400 mesh calcium carbonate powder, and the weight ratio of the three is 1: 1:1) and 435g manganese ore powder (Norway Elkem, micromax), stirring at high speed for 20min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com