Wall drilling device for building construction and drilling method

A technology for construction and drilling devices, applied in work accessories, manufacturing tools, stone processing tools, etc., can solve problems such as inconvenient operation and hole position deviation, reduce work intensity, ensure safety, and avoid oil pipe rupture or sealing damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

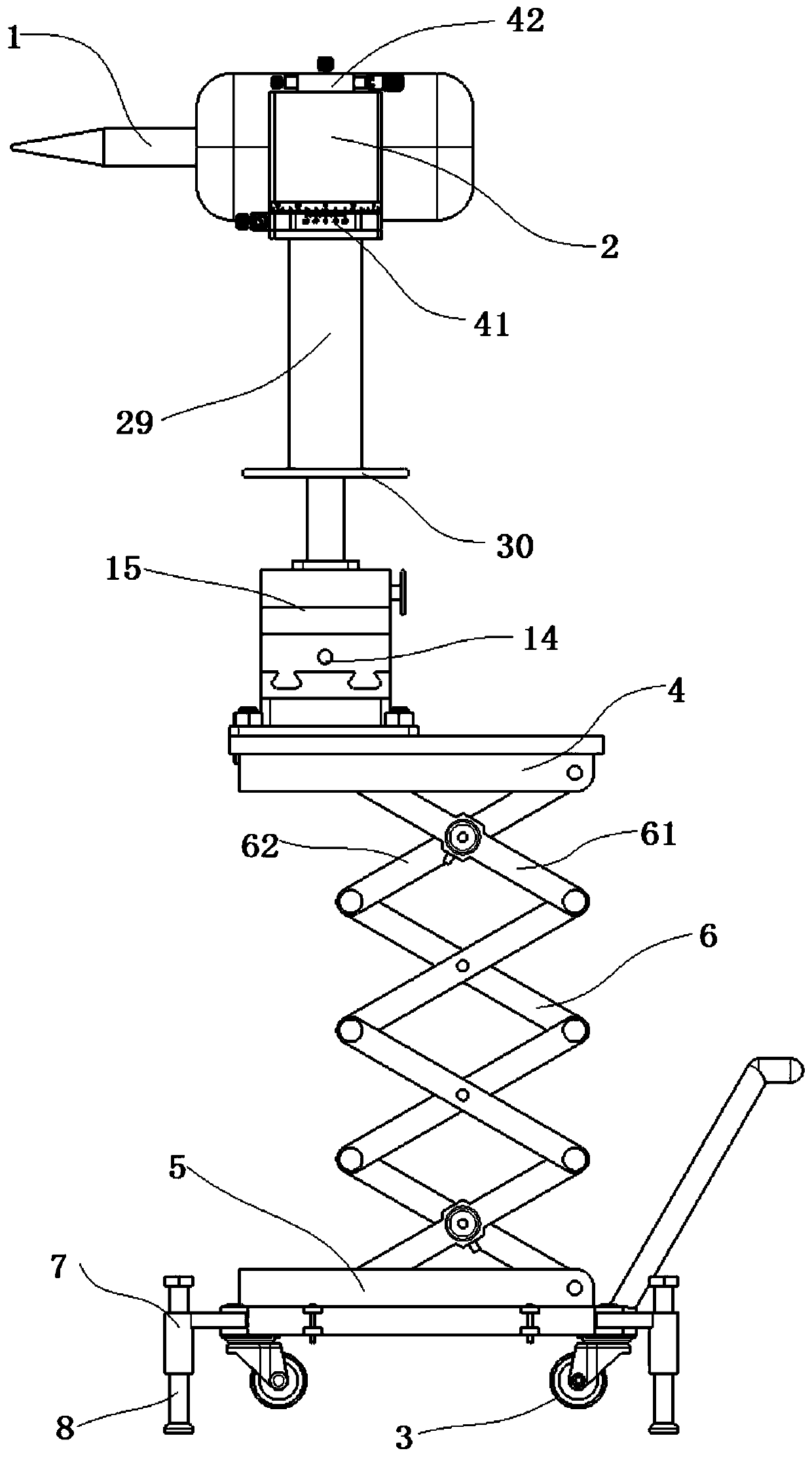

[0034] Such as figure 1 As shown, a wall drilling device for building construction includes a lifting trolley and an electric drill body 1. The top of the lifting trolley is provided with a position adjustment platform, and the top of the position adjustment platform is provided with a height adjustment device. The top of the height adjustment device is provided with a rotary table 41, the top of the rotation is provided with a mounting block 2, the side wall of the mounting block 2 is provided with a turning device 42, and the electric drill body 1 is fixedly connected with the turning device, The position adjustment table is used to adjust the position of the electric drill body 1 on the horizontal plane, the height adjustment device is used to adjust the height of the electric drill body 1, and the rotary table 41 is used to control the rotation of the electric drill body 1 in a plane, The turning device 42 is used to control the pitch angle of the electric drill body 1 . ...

Embodiment 2

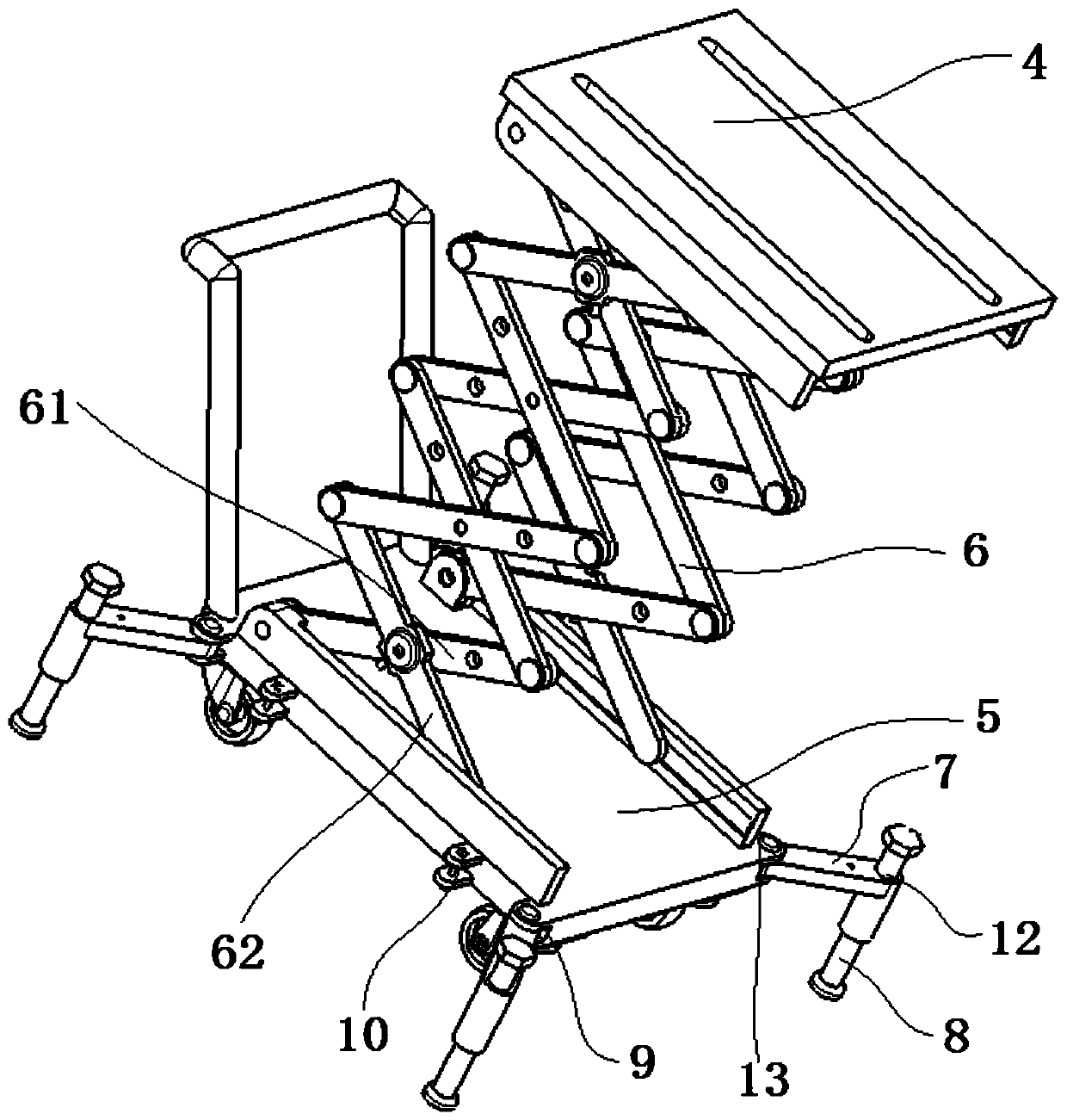

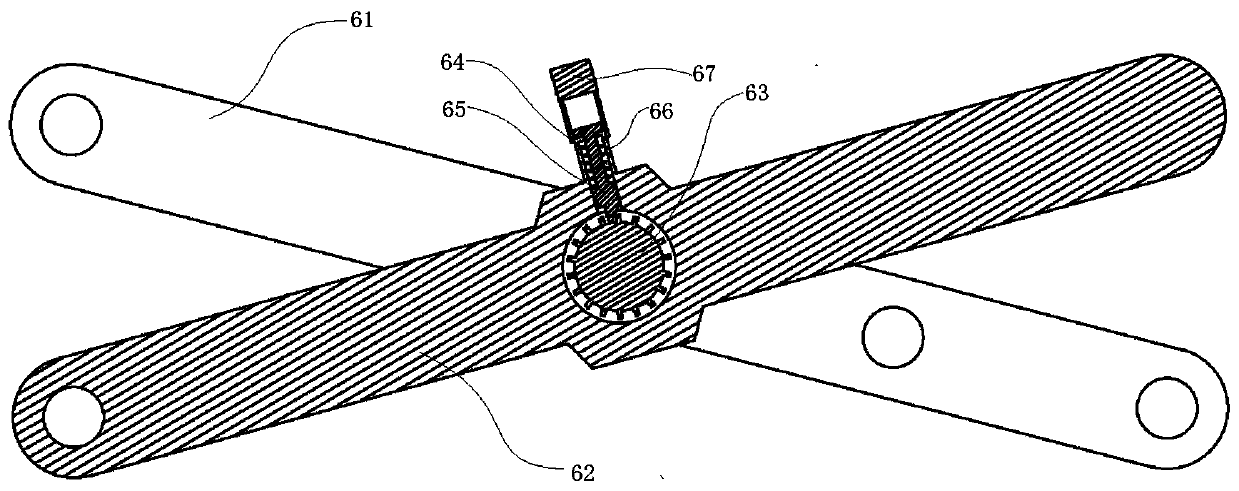

[0036] Such as figure 2 As shown, the present embodiment is basically the same as Embodiment 1, the difference is that the lifting trolley includes an upper plate 4, a lower plate 5, a lifting device, and the bottom of the lower plate 5 is provided with several universal guide wheels 3 , the bottom of the lifting device is fixedly connected to the top of the lower plate 5, the top of the lifting device is fixedly connected to the bottom surface of the upper plate 4, the lifting device can lift the upper plate 4, and the position adjustment is arranged on the on top of plate 4. The lifting device includes two sets of scissor-type support frames 6 and a power device for driving the expansion and contraction of the scissor-type support frames, and the two groups of scissor-type support frames are located between the upper plate 4 and the lower plate 5, and The tops of the two groups of scissor-type support frames are fixedly connected to the upper board 4 respectively, and the ...

Embodiment 3

[0039] Such as figure 2 As shown, this embodiment is basically the same as Embodiment 2, except that the position adjustment table includes a first displacement adjustment mechanism 14 and a second displacement adjustment mechanism 15, and the first displacement adjustment mechanism 14 and the second displacement adjustment mechanism Adjusting mechanism 15 all comprises support plate 16, moving plate 17, screw rod 18, first bearing 19, first hand wheel 20, and the top of described support plate 16 is provided with guide groove 21 and threaded seat 22, and the middle part of described threaded seat 22 A screw hole 23 matched with the screw rod 18 is provided, a slide rail 24 matched with the guide groove 21 is provided at the bottom of the moving plate 17 and the threaded seat 22 is stretched into the groove one 25, the groove one Both ends of 25 are provided with installation holes 26, the first bearing 19 is installed in the installation holes 26, the moving plate 17 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com