Drilling-splitting trolley

A trolley and frame technology, applied in the field of drilling and splitting trolleys, can solve the problems of reduced drilling and splitting construction efficiency, low drilling and splitting construction efficiency, and many action combinations, so as to save time for hole alignment, improve construction safety, and improve The effect of construction environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

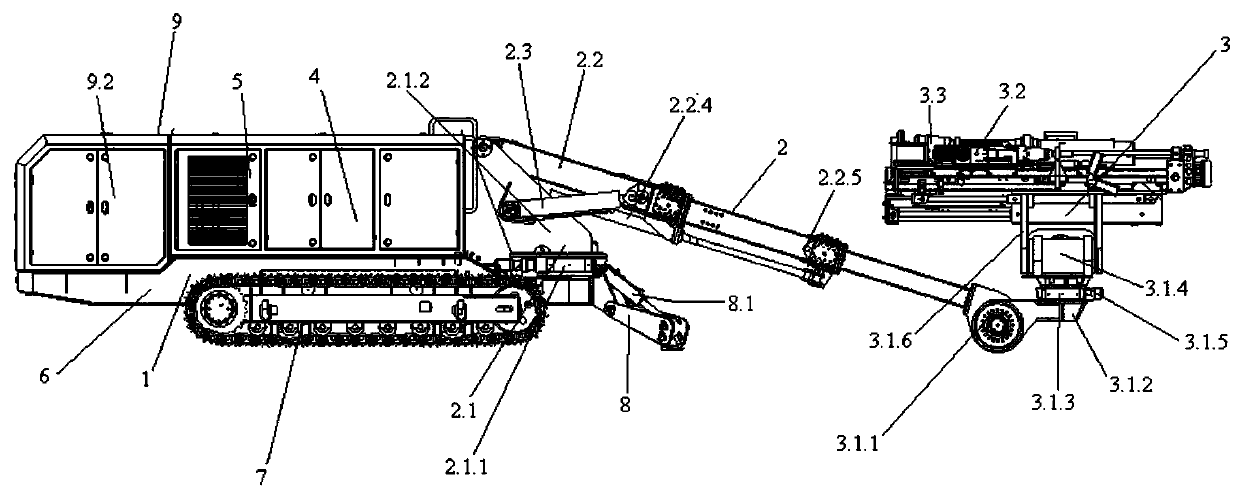

[0045] see figure 1 , a drilling and splitting jumbo, a drilling and splitting jumbo, including a chassis 1, a boom mechanism 2, a drilling and splitting mechanism 3, a hydraulic system 4 and an electric control system 5;

[0046] A vehicle frame 6 is provided on the chassis 1, a crawler belt 7 is provided at the bottom of the vehicle frame 6, and a freely retractable leg 8 is provided at the front of the vehicle frame 6;

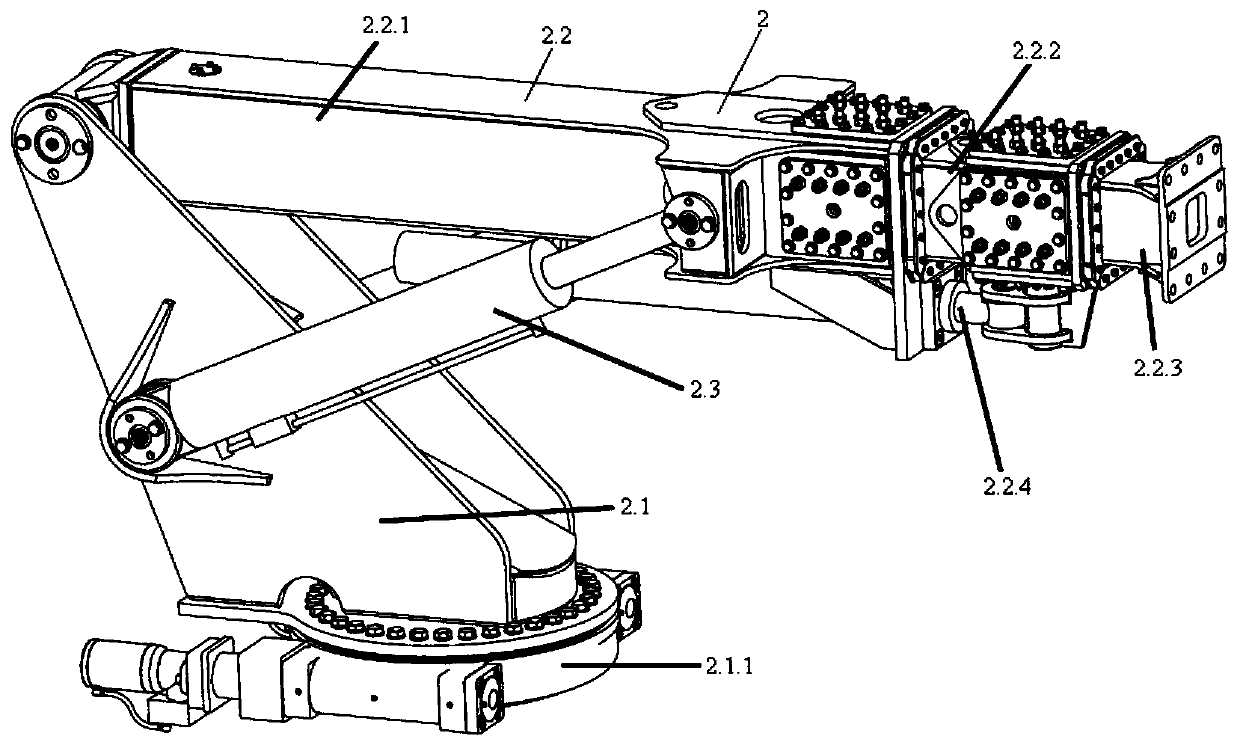

[0047] see figure 2 , the boom mechanism 2 includes a slewing platform 2.1 arranged at the front of the chassis, a telescopic arm 2.2 connected to the slewing platform 2.1 at one end, and a pitch cylinder 2.3 arranged between the slewing platform 2.1 and the telescopic arm 2.2, the slewing platform 2.1 It is used to drive the telescopic arm 2.2 to swing left and right, and the telescopic arm 2.2 moves up and down through the expansion and contraction of the pitch cylinder 2.3;

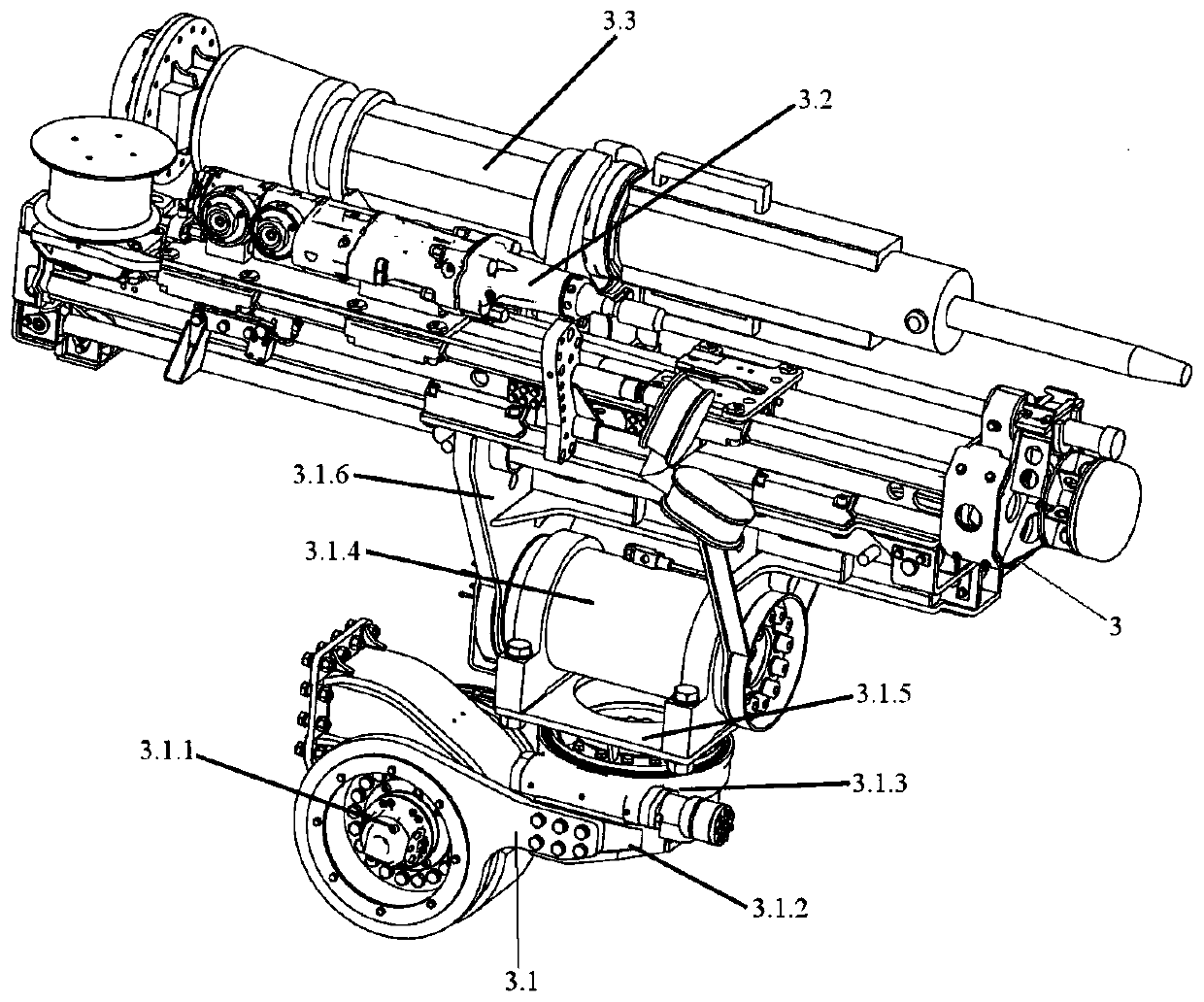

[0048] see image 3 , the drilling and splitting mechanism 3 includes a rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com