Tackifier for drilling fluid and preparation method thereof

A technology of tackifier and drilling fluid, applied in the field of tackifier for drilling fluid and its preparation, can solve the problems of low temperature resistance, poor high temperature stability of temperature resistance, etc., achieve strong rock-carrying energy, improve lubricity, The effect of hydrodynamic volume increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

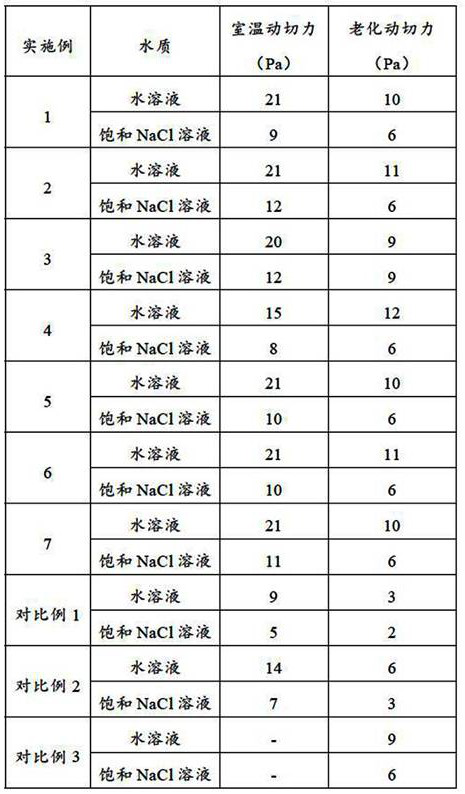

Examples

preparation example Construction

[0039] The invention provides a preparation method of a viscosity enhancer for drilling fluid, the preparation method comprising:

[0040] The quaternization reaction of unsaturated amino acid ester and halogenated alkane is carried out to obtain long-chain hydrophobic monomer;

[0041] The long-chain hydrophobic monomer, acrylamide, acrylic acid, sulfonic acid-based monomer, surfactant, deionized water, pH adjuster and initiator are polymerized to obtain a tackifier for drilling fluid;

[0042] The parts by weight of the raw materials used in the preparation of the tackifier for drilling fluids are as follows: 3 to 8 parts of long-chain hydrophobic monomers (for example, 3 parts, 4 parts, 5 parts, 6 parts, 7 parts or 8 parts), 150-180 parts of acrylamide (for example, it can be 150 parts, 152 parts, 155 parts, 160 parts, 165 parts, 170 parts, 175 parts or 180 parts), acrylic acid 40-70 parts (for example, it can be 40 parts, 45 parts parts, 50 parts, 55 parts, 60 parts, 65 p...

Embodiment 1

[0087] Preparation of long-chain hydrophobic monomers:

[0088] 157 parts of dimethylaminoethyl methacrylate and 52 parts of deionized water were added to the reactor, and after thorough mixing, 204 parts of 1-chlorododecane was added dropwise at 25°C, and the temperature range was controlled to be 40-45 ℃, after the dropwise addition is completed, keep the temperature at 40~45 ℃ for 5 hours, then add 7 parts of acetic acid and mix well to obtain a long-chain hydrophobic monomer.

[0089] Preparation of viscosifier for drilling fluid:

[0090] 3 parts of long-chain hydrophobic monomer, 150 parts of acrylamide, 40 parts of acrylic acid, 5 parts of sodium 2-acrylamido-2-methylpropanesulfonate, 0.1 part of tetrabutylammonium bromide and 771 parts of deionized water Mix well to obtain a mixed solution, add 31 parts of potassium hydroxide to the mixed solution, adjust the pH to 7.1, and then add 0.006 part of initiator (including 0.002 part of sodium hypophosphite and 0.002 part of ...

Embodiment 2

[0092] Preparation of long-chain hydrophobic monomers:

[0093] 190 parts of dimethylaminoethyl methacrylate and 60 parts of deionized water were added to the reactor, and after thorough mixing, 263 parts of 1-chlorotridecane was added dropwise at 25°C, and the temperature range was controlled to be 40-45 ℃, after the dropwise addition is completed, keep the temperature at 40~45℃ for 7 hours, then add 10 parts of acetic acid and mix well to obtain a long-chain hydrophobic monomer.

[0094] Preparation of viscosifier for drilling fluid:

[0095] 8 parts of long-chain hydrophobic monomers, 180 parts of acrylamide, 70 parts of acrylic acid, 20 parts of sodium 2-acrylamido-2-methylpropanesulfonate, 0.5 parts of tetrabutylammonium bromide and 667 parts of deionized water Mix well to obtain a mixed solution, add 55 parts of potassium hydroxide to the mixed solution, adjust the pH to 7.5, and then add 0.01 part of an initiator (including 0.003 part of sodium hypophosphite and 0.004 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com