Method for preparing high-viscosity organic bentonite by virtue of calcium-based bentonite

A calcium-based bentonite and bentonite technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as inability to effectively fix and affect the performance of organic bentonite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

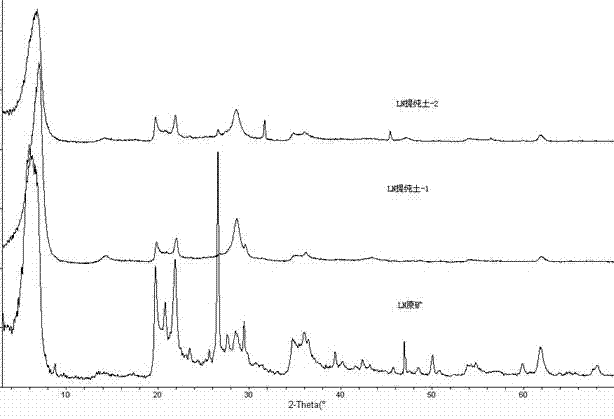

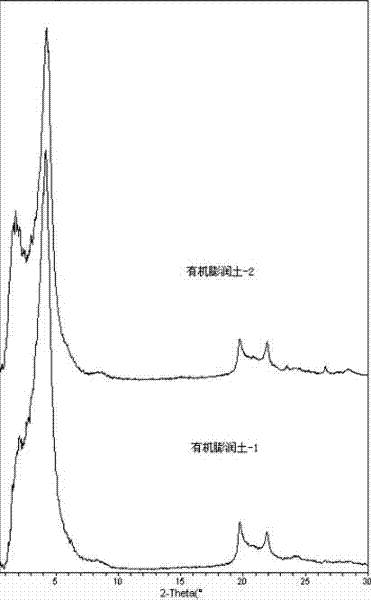

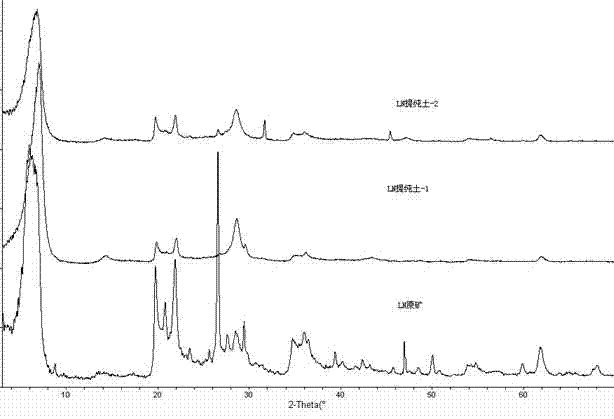

[0027] Weigh 600g Zhejiang Anji bentonite raw ore powder, disperse in hydrochloric acid aqueous solution (30ml concentrated HCl, 1.8L water) under stirring condition, stir well, let stand at room temperature and soak for 2d, press filter and dehydrate, add 5L water to the filter cake to make slurry, Add 15.1g of sodium fluoride and 1g of tannic acid, stir for 1h at room temperature, centrifuge, and take the supernatant; heat the suspension to 50-80°C, add quaternary ammonium salt modifier, stir at constant temperature for 1h, wash, press Filtrate and dehydrate to obtain a waxy body, dry at 85°C, and pulverize to 200 mesh to obtain organobentonite AJ-1.

Embodiment 2

[0029] Weighed 600g of bentonite raw ore powder (raw ore MB 24.0%) from a place in Liaoning, and carried out the same method as in Example 1 to obtain organobentonite LN-1.

Embodiment 3

[0031] The implementation method is the same as in Example 1, using Zhejiang Anji bentonite raw ore as raw material, changing the acid solution to nitric acid solution to obtain organobentonite AJ-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com