Desulfurizing agent for reforming stock oil and preparation method thereof

A technology of desulfurizer and raw material oil, which is applied in the field of desulfurizer, can solve the problems of complicated production process, high cost of desulfurizer, short service life, etc., and achieve the effects of simplifying the process, expanding the range of raw materials, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

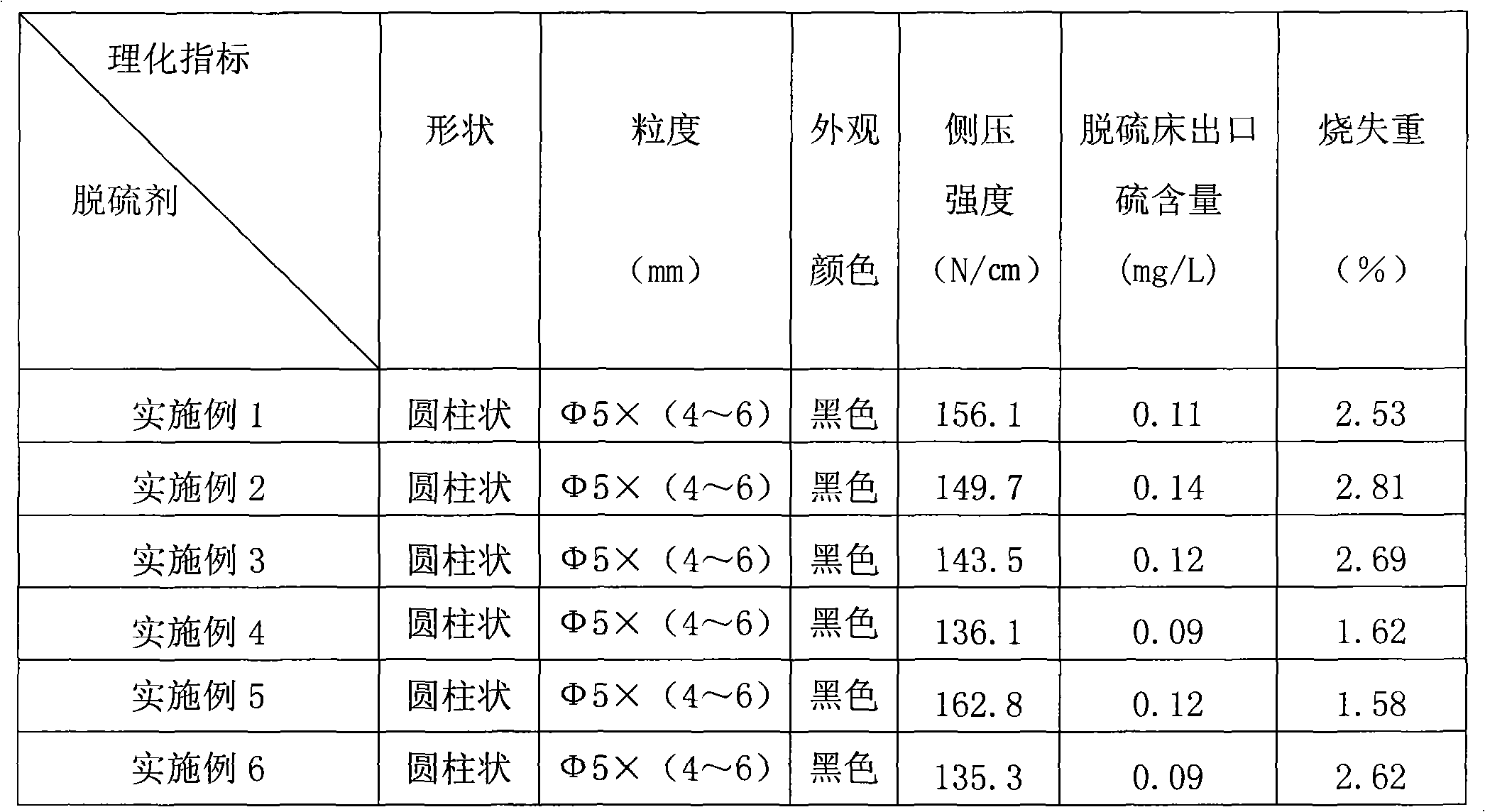

Embodiment 1

[0025] Weigh 28.2g of powdery active zinc oxide, 27.9g of powdery active nickel oxide, 32.0g of diatomaceous earth and 11.9g of high-alumina cement, then add 1-2g of graphite, mix well, and press it into a cylinder of ф5×4-6 .

Embodiment 2

[0027] Weigh 36.9g of powdery active zinc oxide, 18.1g of powdery active nickel oxide, 18.5g of pentonite and 25.5g of zeolite, then add 1-2g of graphite, mix evenly, and press into a cylindrical shape of ф5×4-6.

Embodiment 3

[0029] Weigh 52.7g of zinc nitrate, add it to a 500ml beaker, add 200ml of water, and stir to dissolve it completely. While stirring, adjust the pH value to about 6.5 with 1.0M NaOH aqueous solution, and then adjust the pH value with 0.1-0.2M ammonia solution to 7.0, place the precipitate for 24 hours, filter, wash the precipitate with water several times until there is no sodium ion in the filtrate, dry and grind the filter cake, add 42.3g powdered activated nickel oxide, 30.0g clay and 14.0g ordinary cement , then add 1~2g of graphite, mix well, and press it into a cylindrical shape of ф5×4~6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com