Novel blending willow

A kind of wool machine, a new type of technology, applied in mechanical treatment, textile and papermaking, fiber mechanical impurity removal, etc., can solve the problems of dust adhesion, hinder the opening effect, fire and other problems, and achieve the effect of eliminating static electricity and good dust removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to enable those skilled in the art to better understand the solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings of the embodiments.

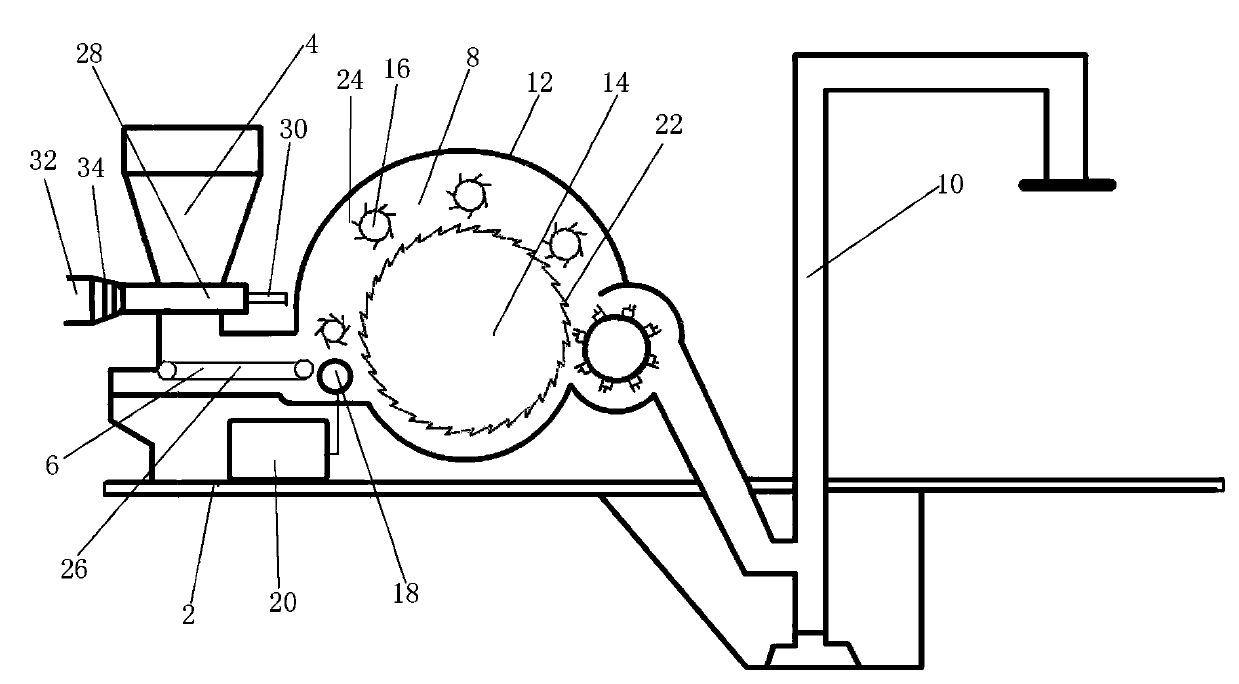

[0016] Such as figure 1 As shown, a new type of kneading machine, including a frame 2, a hair storage box 4, a hair feeding part 6, an opening part 8, and a hair output tube 10 arranged in sequence on the frame 2 and connected internally along the direction of the kneading process. The opening part 8 includes a box body 12, an opening roller 14 passing through the box body 12, a plurality of work rolls 16 located in the box body 12 and arranged along the upper half circumference of the opening roller 14, and the present invention preferably works There are three rollers 16, and they are arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com