Energy-saving fine down feather production device

A production device and down technology, which is applied in the field of down production, can solve the problems of long down treatment cycle, incapable down treatment, and large space occupation, and achieve the effects of reducing cleaning time, compact structure, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

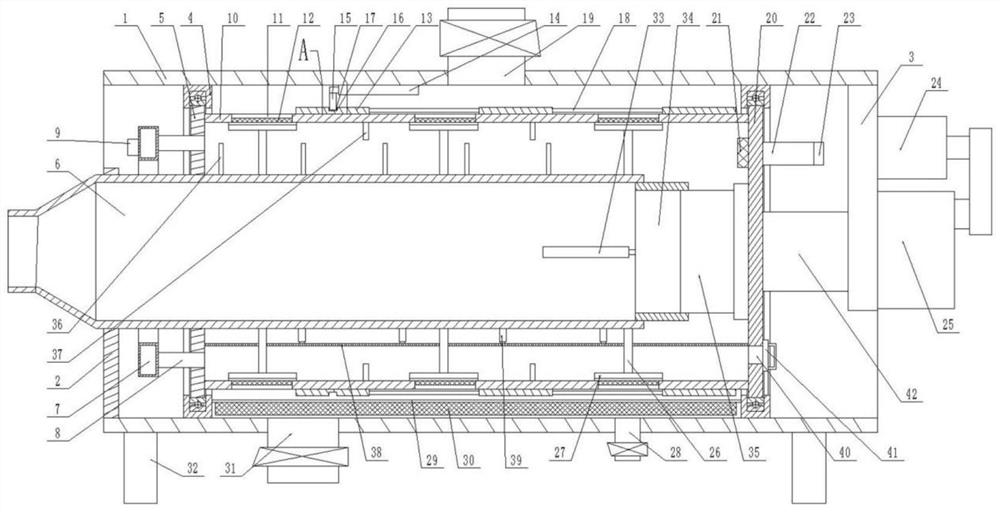

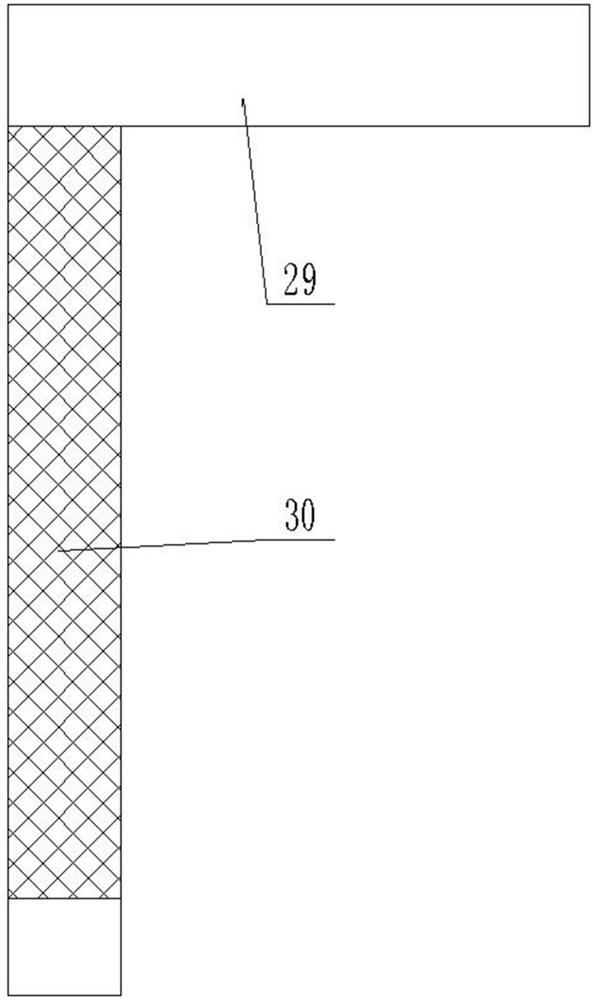

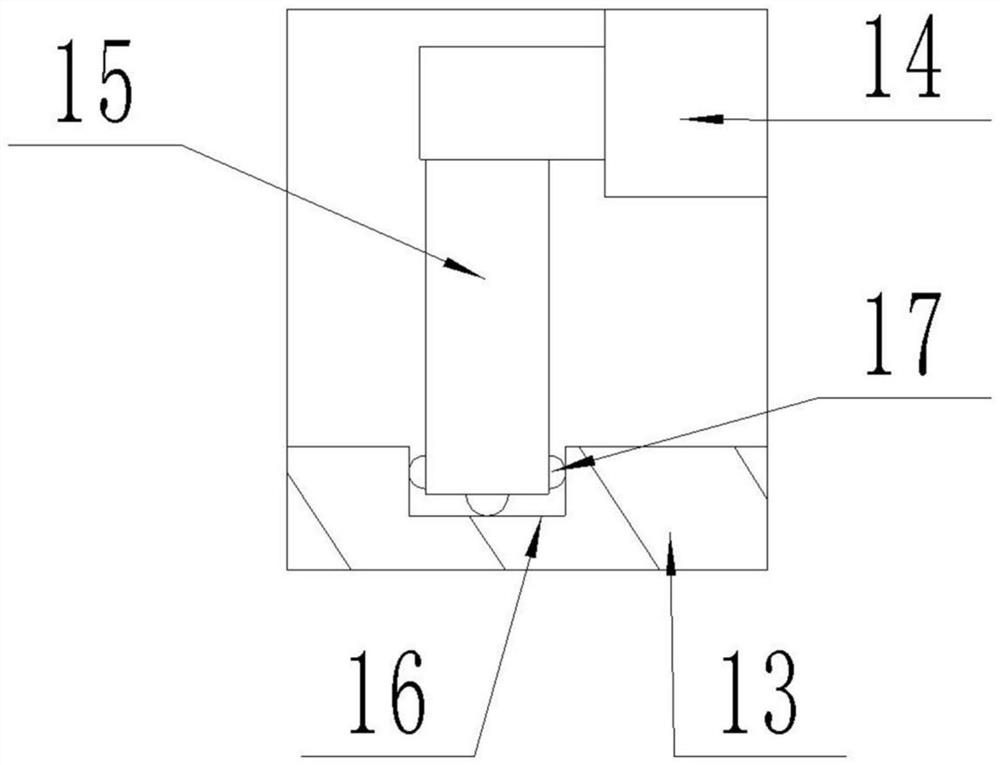

[0016] Such as Figure 1-4 As shown, an energy-saving refined down production device includes a jacket 1, two supports 32 are fixed on the lower end of the jacket 1, two fixed rings 4 arranged on the left and right are fixed inside the jacket 1, and the core pipe 6 runs through the left side The fixed ring 4 of the fixed ring 4 on the left side is fixed with a collar 5 on the inner core tube 6 of the fixed ring 4 on the left side, and the collar 5 is connected with the fixed ring 4 on the left side in a rotating and sealed connection, and the fixed ring 4 on the right side is connected with a blocking plate in a rotating and sealed manner 20. The left end of the blocking plate 20 is rotationally and sealedly connected with a fixed column 35. The fixed column 35 is covered with a connecting sleeve 34. The connecting sleeve 34 is connected to the fixed column 35 in a sliding and sealed manner. The left end of the connecting sleeve 34 is plugged into the core tube 6 and slides wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com