Process and arrangement for replacing intra-fiber liquid in fibers with a replacement liquid

a technology of fiber liquid and fiber wall, which is applied in the direction of water/sludge/sewage treatment, washing apparatus, application, etc., can solve the problems of fiber wall pores and lumens that have not been the object of attention, high energy consumption and excessive stress in the machinery used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

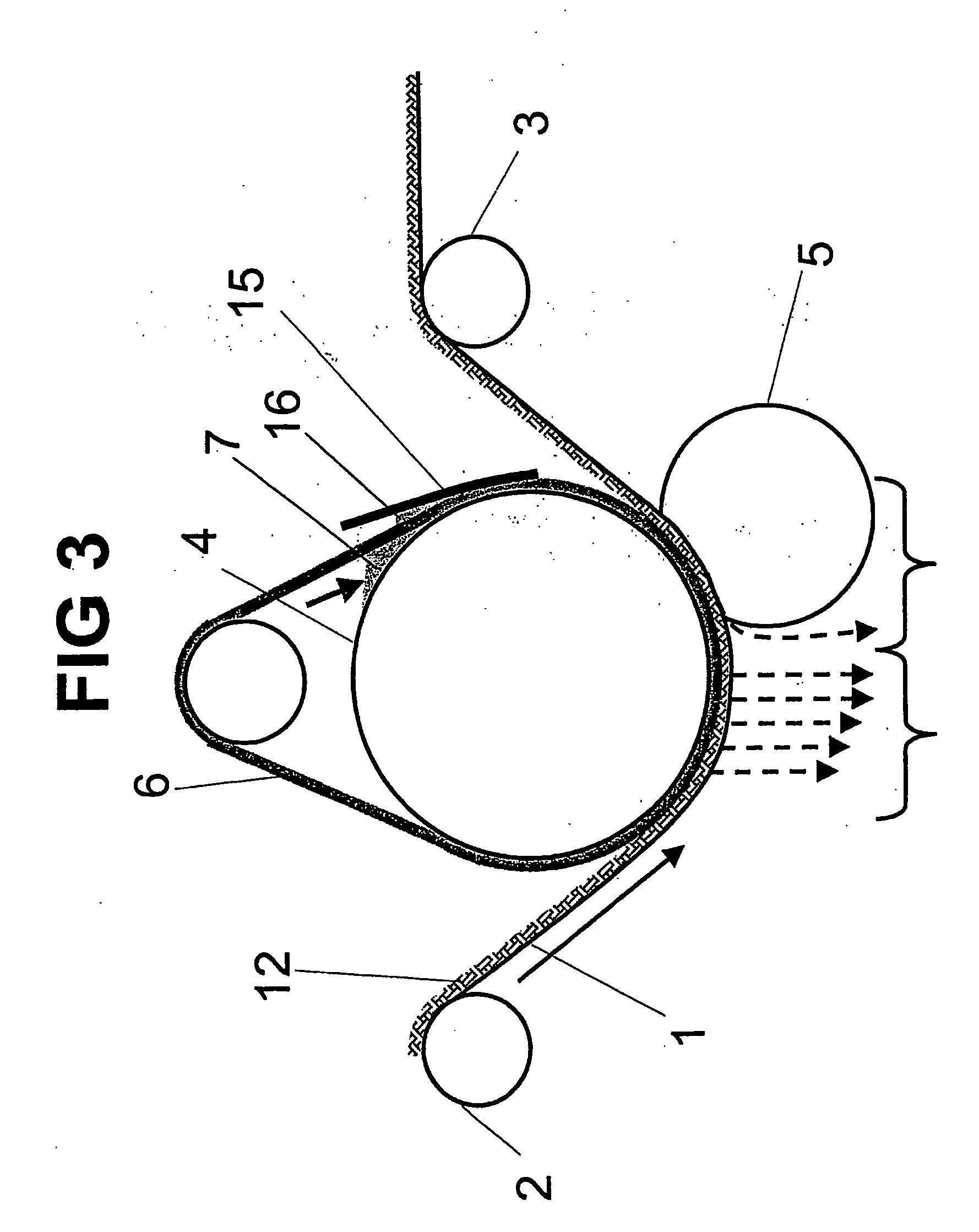

[0038]FIG. 7 is illustrating a process according to the invention having the following steps; compressing a fiber cake to such a degree that a substantial quantity of the contaminated intra-fiber liquid is expressed to the space between the fibers and partially out of the fiber cake. At the same time a replacement liquid is forcibly supplied to the fiber cake during the compression and displacing the intra-fiber liquid from the space between the fibers. This means that the residual contaminated liquid is greatly diluted and getting even more so when in an expansion phase the fibers expand while supplying additional replacement liquid which liquid is thus further absorbed by the expanding fibers. The whole process means that an exchange or replacement has taken place where the replacement liquid has replaced the contaminated liquid not altogether but in such a degree that the content of the contaminant in the treated fibers is diluted in a high degree.

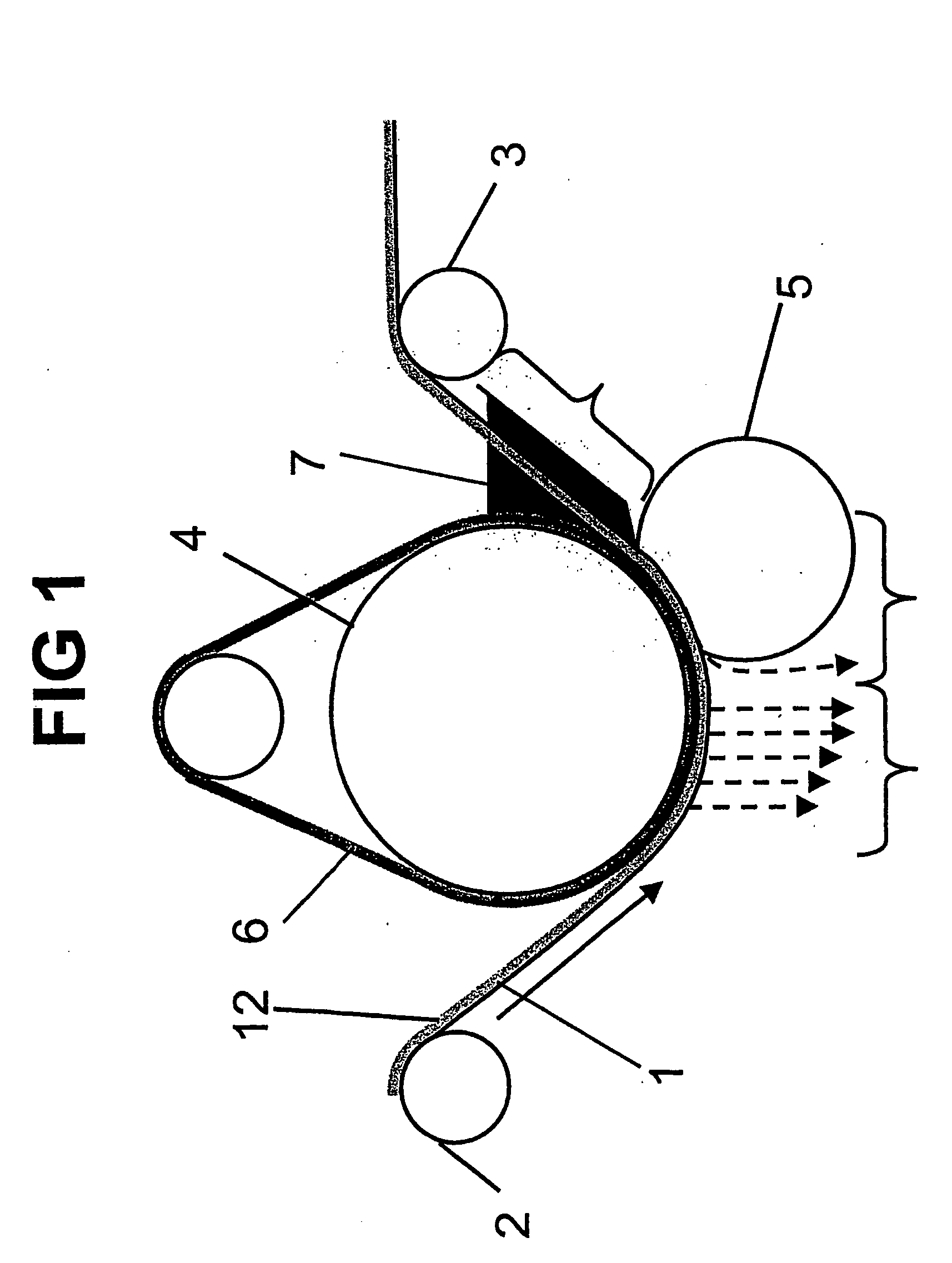

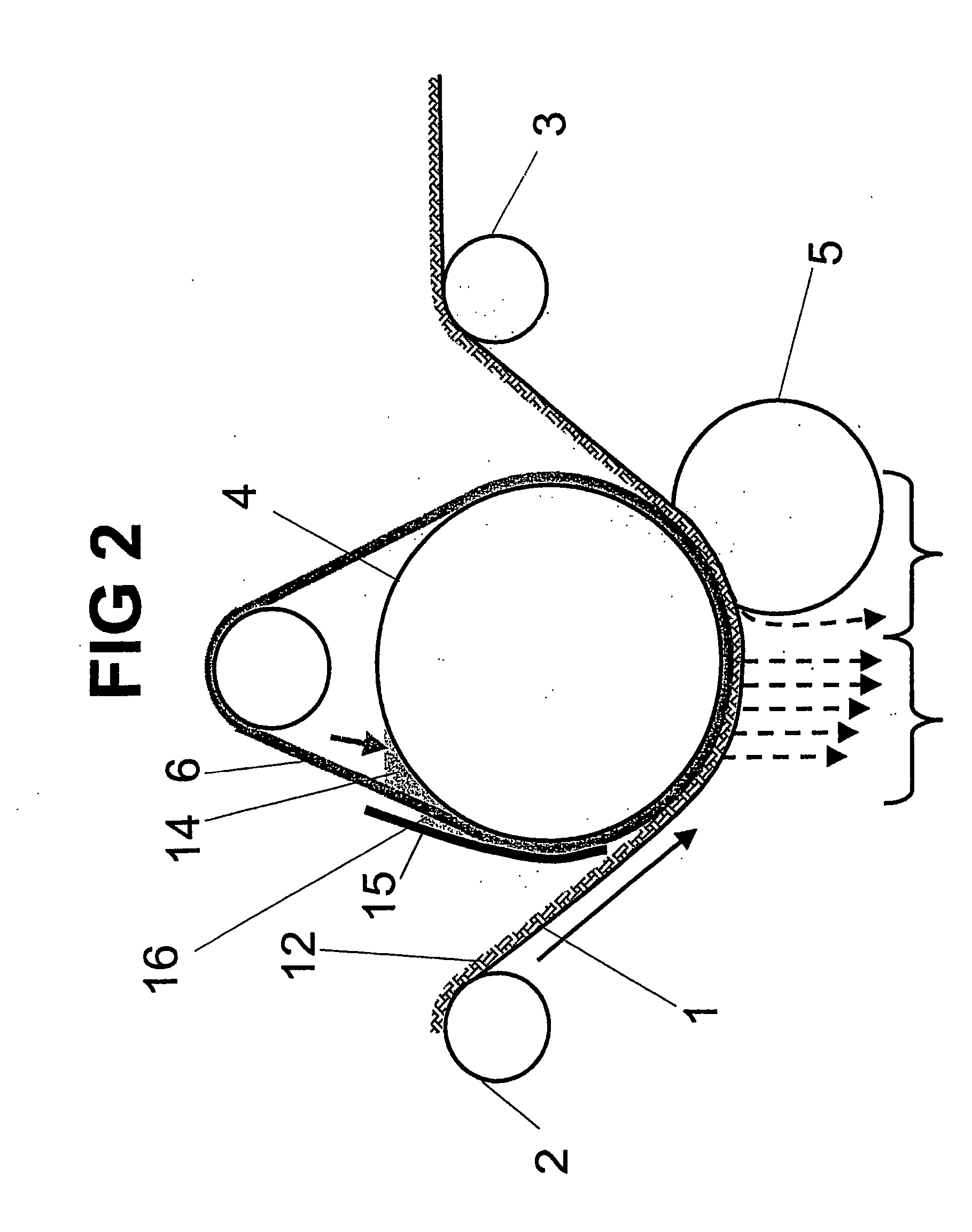

[0039] According to FIG. 1, a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| chemical treating | aaaaa | aaaaa |

| fluorescent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com