Manufacturing process of novel down quilt

A production process and technology for down quilts, applied in textiles and papermaking, mechanical treatment, fiber treatment, etc., can solve the problems of poor thermal insulation effect of down quilts, high prices of down quilts, entry of cold air, etc., to improve user experience, wear resistance, etc. Good performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

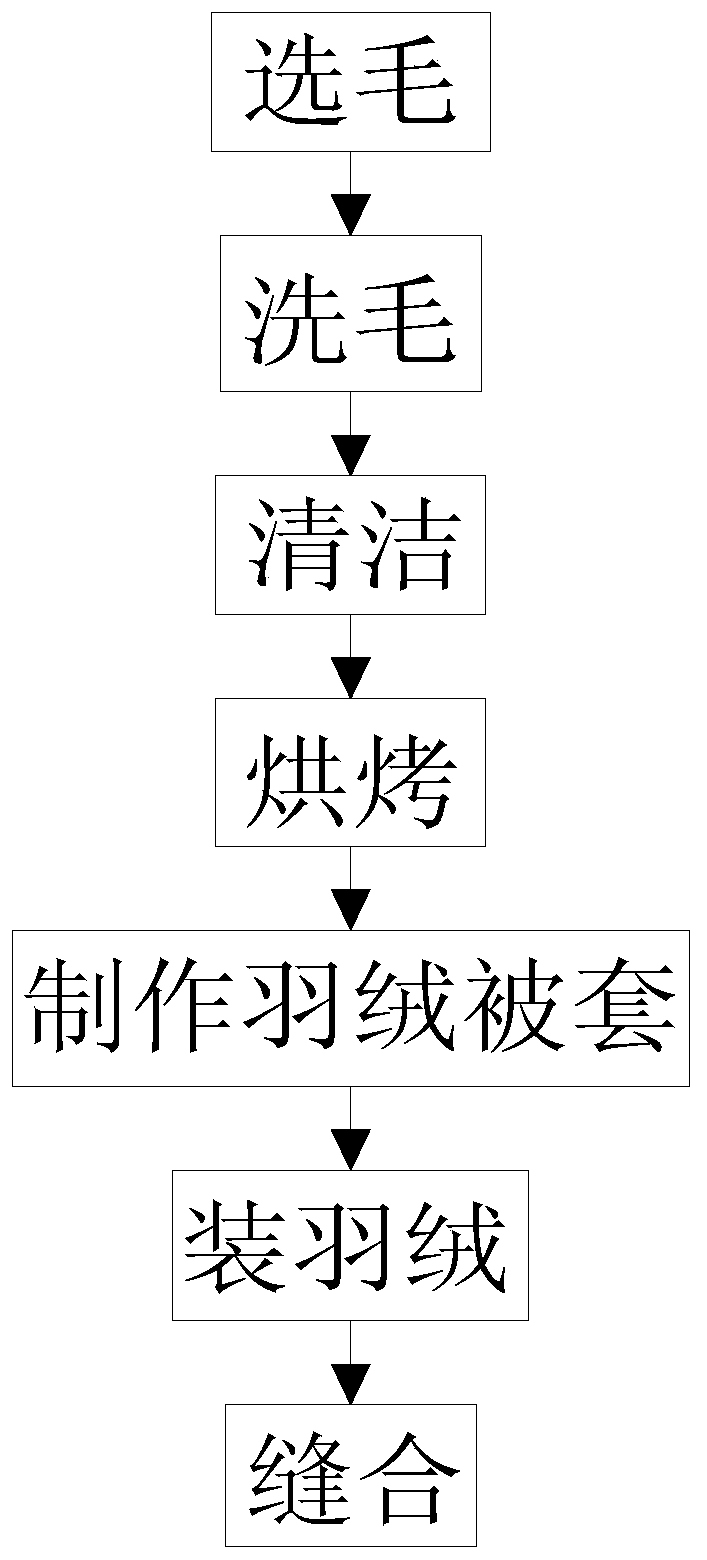

Image

Examples

Embodiment 1

[0030] A kind of manufacture craft of novel duvet, comprises the steps:

[0031] a, hair selection: carry out dry plucking to the slaughtered geese and ducks, cut off the pinnae with scissors, remove the quills, and remove impurities in the feathers;

[0032] b. Wool washing: put the feathers screened in step a into a cloth bag with dense latitude and longitude and tighten the mouth of the bag, throw the cloth bag into pure water dissolved with laundry detergent for stirring, and soak for 2 hours to achieve feather degreasing, The purpose of sterilization, killing mites, feather lice and their eggs, while removing the fishy smell of feathers;

[0033] c. Cleaning: take out the feather obtained after stirring and cleaning in step b and rinse it repeatedly with clear water, and then dehydrate it with a dehydrator;

[0034] d, baking: put the feathers cleaned in step c into a baking machine and bake until the moisture in the feathers is dried;

[0035] e. Making duvet jackets: ...

Embodiment 2

[0048] A kind of manufacture craft of novel duvet, comprises the steps:

[0049] a, hair selection: carry out dry plucking to the slaughtered geese and ducks, cut off the pinnae with scissors, remove the quills, and remove impurities in the feathers;

[0050] b. Wool washing: Put the feathers screened in step a into a cloth bag with dense latitude and longitude and tighten the bag mouth, throw the cloth bag into pure water dissolved in laundry detergent for stirring, and soak for 3 hours; to achieve degreasing and sterilization of feathers Disinfect and kill mites, feather lice and their eggs, while removing the fishy smell of feathers;

[0051] c. Cleaning: take out the feather obtained after stirring and cleaning in step b and rinse it repeatedly with clear water, and then dehydrate it with a dehydrator;

[0052] d, baking: put the feathers cleaned in step c into a baking machine and bake until the moisture in the feathers is dried;

[0053] e. Making duvet jackets: Select...

Embodiment 3

[0066] A kind of manufacture craft of novel duvet, comprises the steps:

[0067] a, hair selection: carry out dry plucking to the slaughtered geese and ducks, cut off the pinnae with scissors, remove the quills, and remove impurities in the feathers;

[0068] b. Wool washing: put the feathers screened in step a into a cloth bag with dense latitude and longitude and tighten the mouth of the bag, throw the cloth bag into pure water dissolved with laundry detergent for stirring, and soak for 4 hours; to achieve feather degreasing, The purpose of sterilization, killing mites, feather lice and their eggs, while removing the fishy smell of feathers;

[0069] c. Cleaning: take out the feather obtained after stirring and cleaning in step b and rinse it repeatedly with clear water, and then dehydrate it with a dehydrator;

[0070] d, baking: put the feathers cleaned in step c into a baking machine and bake until the moisture in the feathers is dried;

[0071] e. Making duvet jackets:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com