Method for producing long bagworm silk threads and production device therefor

A production device and a technology for the moth, which are applied in silk fiber production, silk reeling, and resistance to vector-borne diseases, etc., can solve problems such as difficulties, high production costs, and low quality, and achieve the effect of easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0141]

[0142] (Purpose)

[0143] Through the production method of the long minion moth silk of the present invention, the scaffold silk of the minion moth is produced.

[0144] (method)

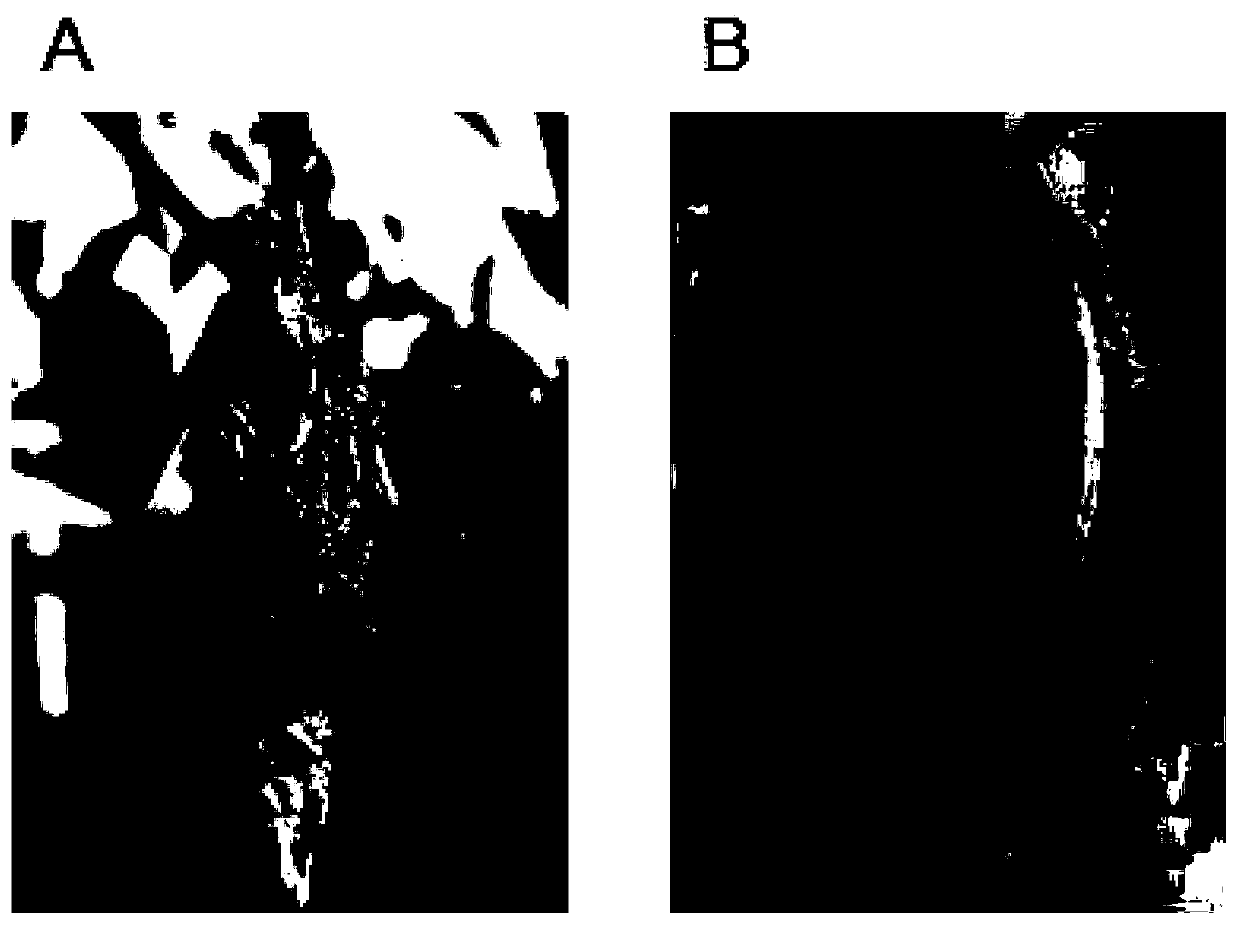

[0145] As the minion moth, the final instar larvae (n=50) of the minion moth collected from an orchard in Tsukuba City, Ibaraki Prefecture were used. The production device of the long minion moth silk uses the production device of the long minion moth silk of the present invention. The production unit uses approximately square metal cans. Above the plate-shaped member corresponding to the side surface of the metal can, there was a closed-loop line with a width of 1.7 mm and a circumference of 1.1 m as an edge portion with the line surface facing upward. Arrange 1 moth insect at the bottom of the container of this metal can. After confirming that the minion moths have arrived at the line, spinning around the line while spinning silk on the line, they are left for 2 days as they are (si...

Embodiment 2

[0154]

[0155] (Purpose)

[0156] Minotaur moths, by their nature, at least spin out scaffolding silk when they move. Therefore, as long as it moves on the line, continuous silk spinning will continue, which is equivalent to the length of the single fiber of the moth silk obtained in the present invention. Therefore, it has been verified that the production device of the long minion moth silk of the present invention can continuously spin silk for several hours.

[0157] (method)

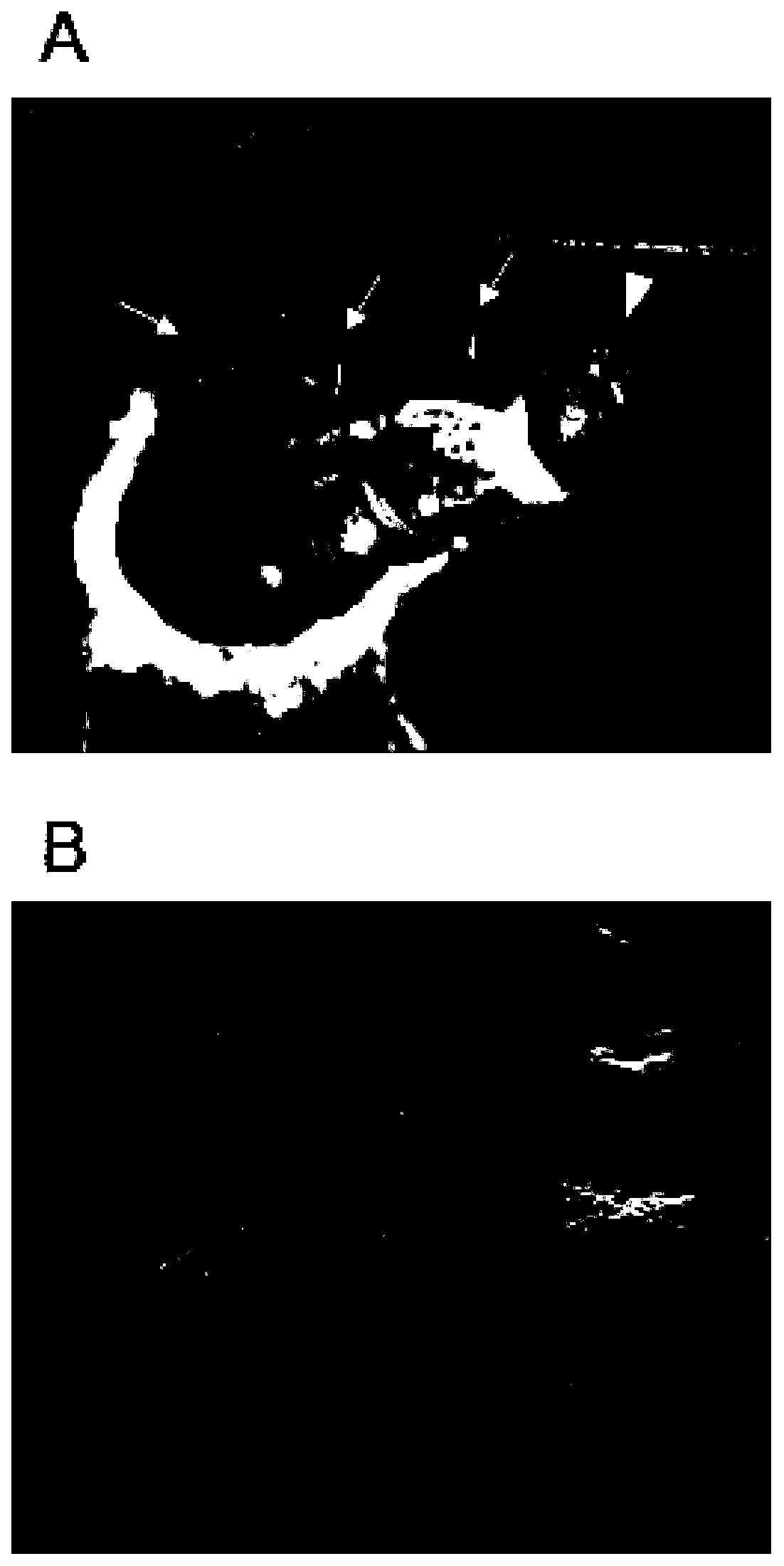

[0158] As the minion moth, the final instar larvae (n=8) of the tea moth collected from trees on the site of the Comprehensive Research Institute for Agricultural and Food Industry Technology were used. The production setup uses a closed loop circuit with a width of 0.85 mm and a circumference of 235 mm in diameter stainless steel petri dish. After arranging the bottom of this stainless steel petri dish, one scorpion moth was placed, and the time from the time point when the scorpion scorpio...

Embodiment 3

[0166]

[0167] (Purpose)

[0168] Verify the mechanical properties of minomoth silk.

[0169] (method)

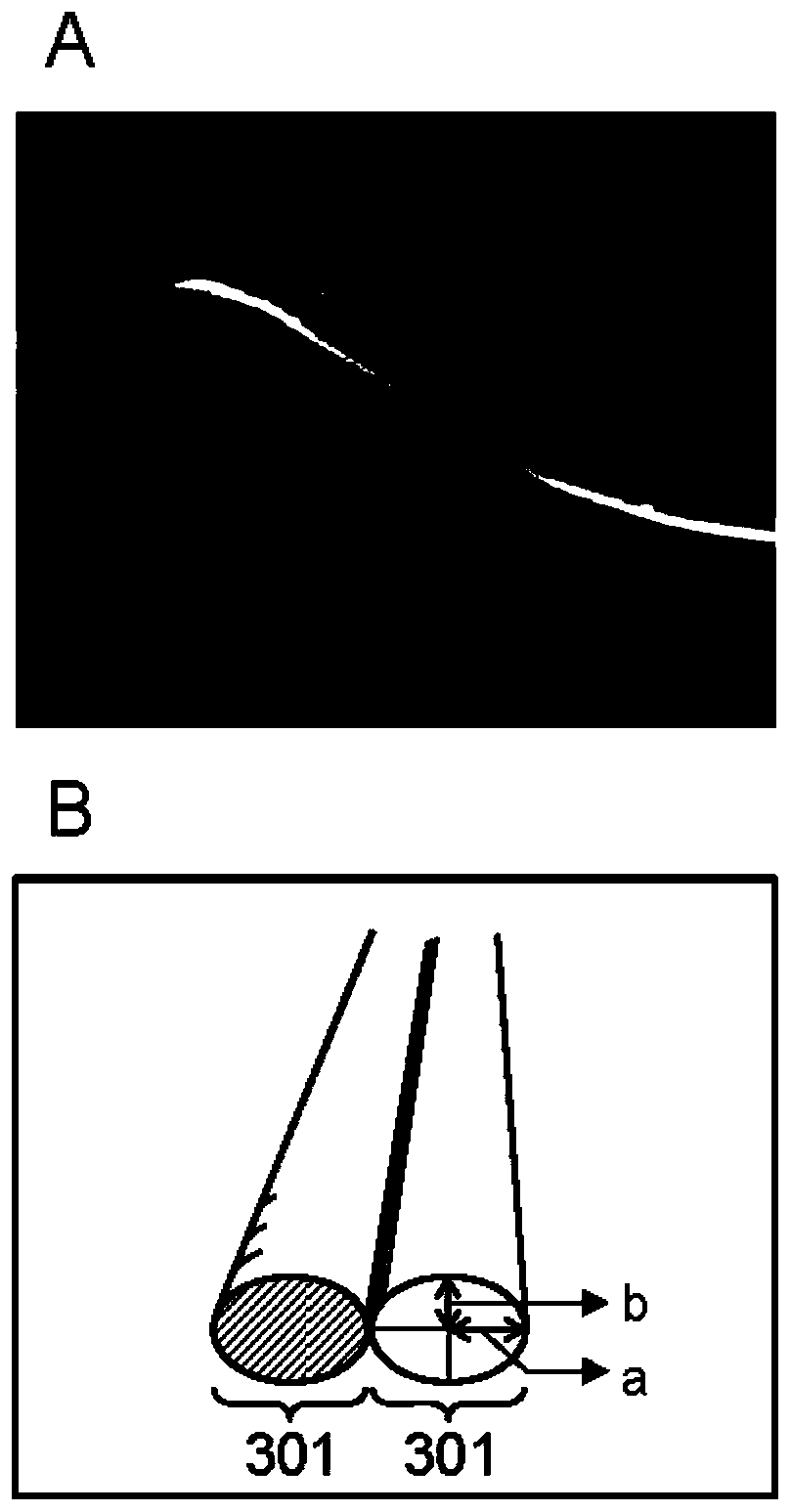

[0170] The silk moth silk uses the spinning fiber (double silk) before scouring. A part (n=9) of the spun fibers obtained after the recovery step of Example 1 was used as the scaffold yarn. In addition, as the nest thread, silk plucked from the innermost layer of the nest of the final-instar larvae of the moth moth (n=5) was used. Nest silk is a sample of approximately 30 mm obtained by cutting the nest of the moth moth by hand from the innermost surface.

[0171] Tensile tests were carried out using each minion silk, and the four mechanical properties of initial elastic modulus, breaking strength, breaking elongation, and toughness were evaluated. Here, the initial modulus of elasticity corresponds to a constant of proportionality in the deformation region that satisfies the proportional relationship between force and deformation when stretching a sample, that is, H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com