Jute fiber loosening machine

A technology of hemp loosening machine and hemp fiber, which is applied in fiber mechanical separation, fiber treatment, mechanical treatment, etc. It can solve the problems of hemp fiber opening cannot be clumped, prolonging the drying time, and investing a lot of manpower, so as to improve the removal rate. Efficiency, time shortening, and labor saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

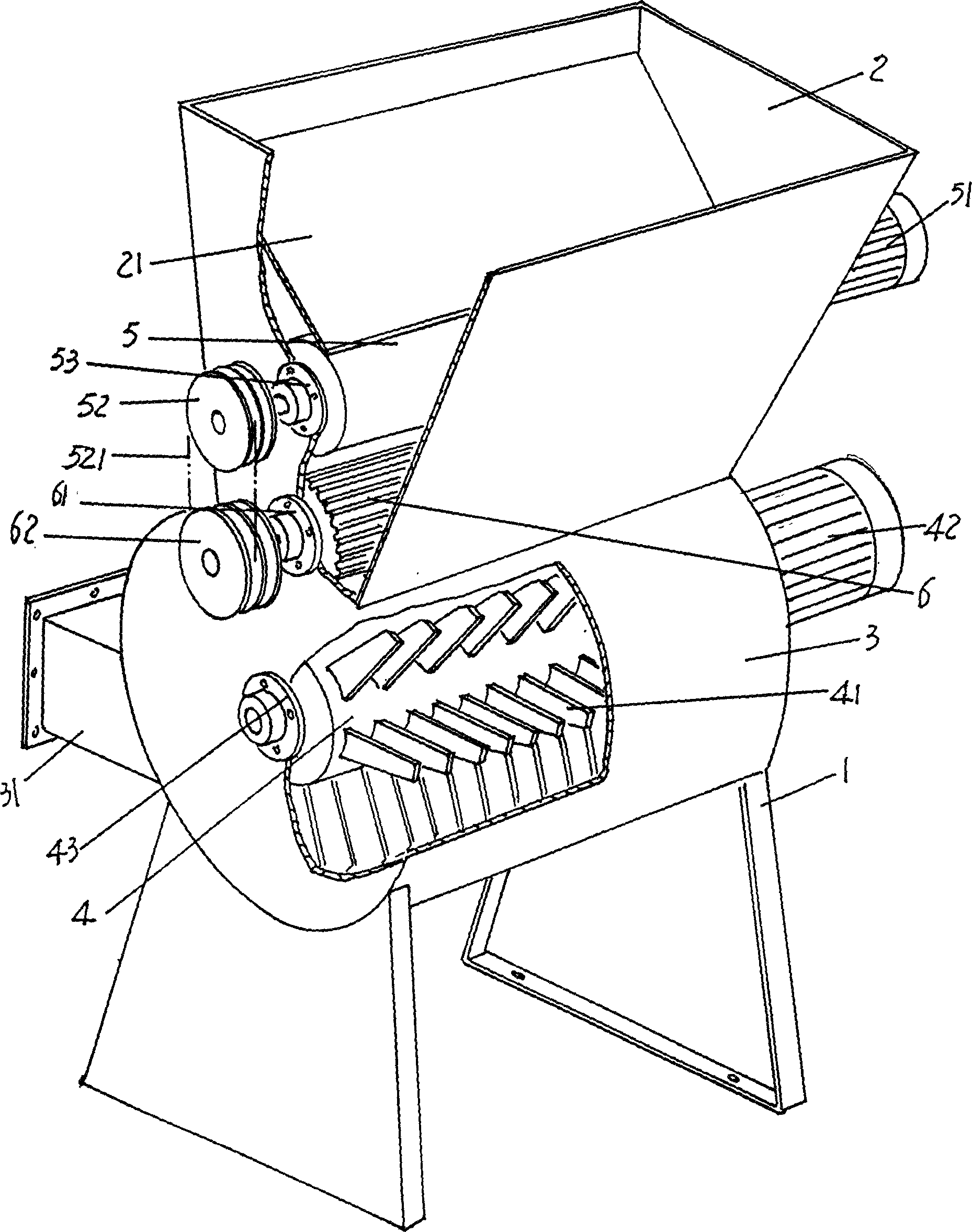

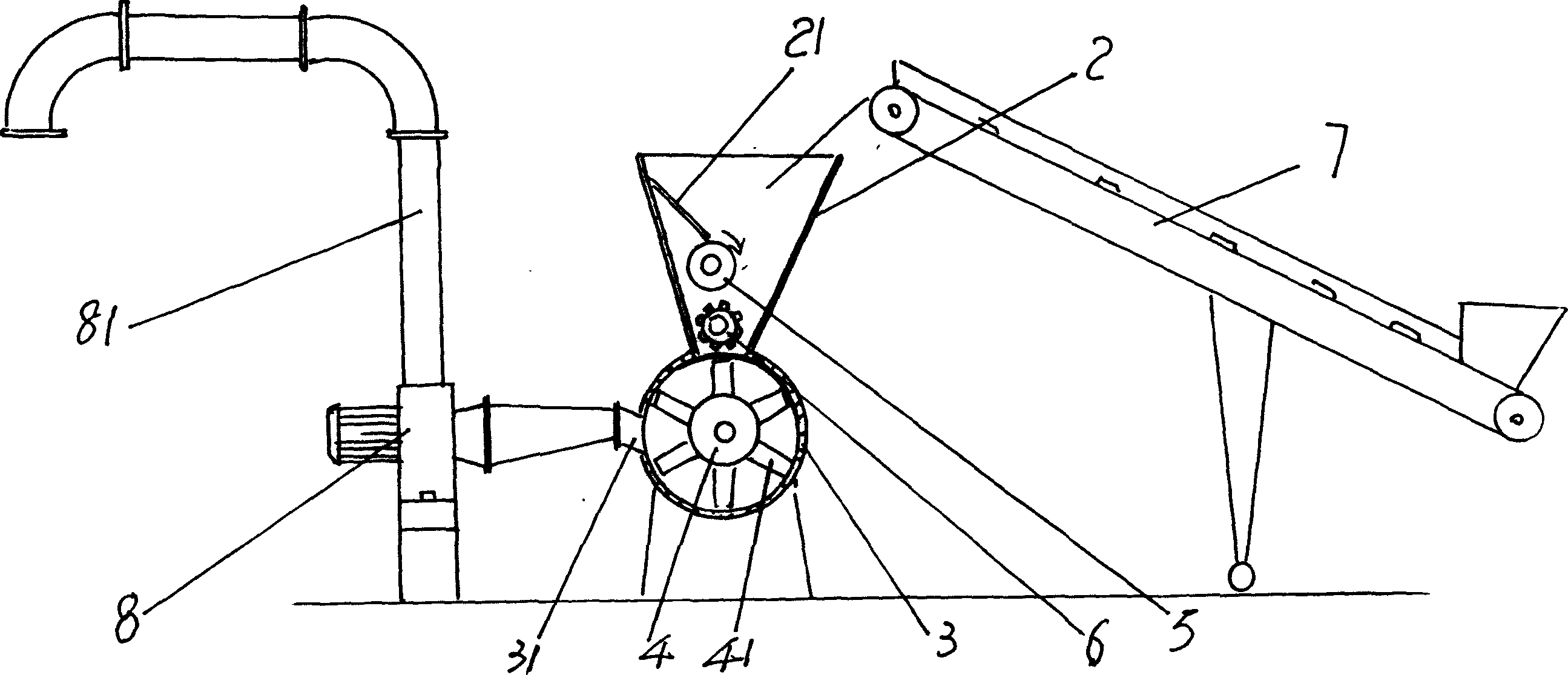

[0023] please see figure 1 , the cylinder body 3 is fixed on the top of the frame 1 by welding or riveting or other similar fixing methods. In this patent, there is no need to limit the shape and specific structure of the frame 1, as long as it can meet the requirements of loosening the cylinder body 3 It only needs to be fixed on the top. The material of the frame 1 is preferably metal, and the bottom can be fixed to the embedded parts on the floor of the workshop through fasteners such as bolts. On one side of the lengthwise direction of the loosening roller body 3 and near one end, a discharge opening 31 for leading out the hemp fiber in the cavity of the loosening roller body 3 is extended. When in use, the discharge port 31 is docked with a hemp blower 8 ( figure 2 Shown), the hemp that is picked up by the loosening roller 4 in the barrel chamber is drawn out by the hemp feeding blower 8. The loosening roller 4 is pivoted on the two ends of the loosening roller body 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com