Comb needle cotton slitting machine

An opener and carding needle technology, which is applied in the field of textile equipment, can solve the problems of unclean fibers, difficult removal of impurities in the internal cavity, and poor removal of impurities, and achieves good carding effect, soft action, and guaranteed cleanliness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

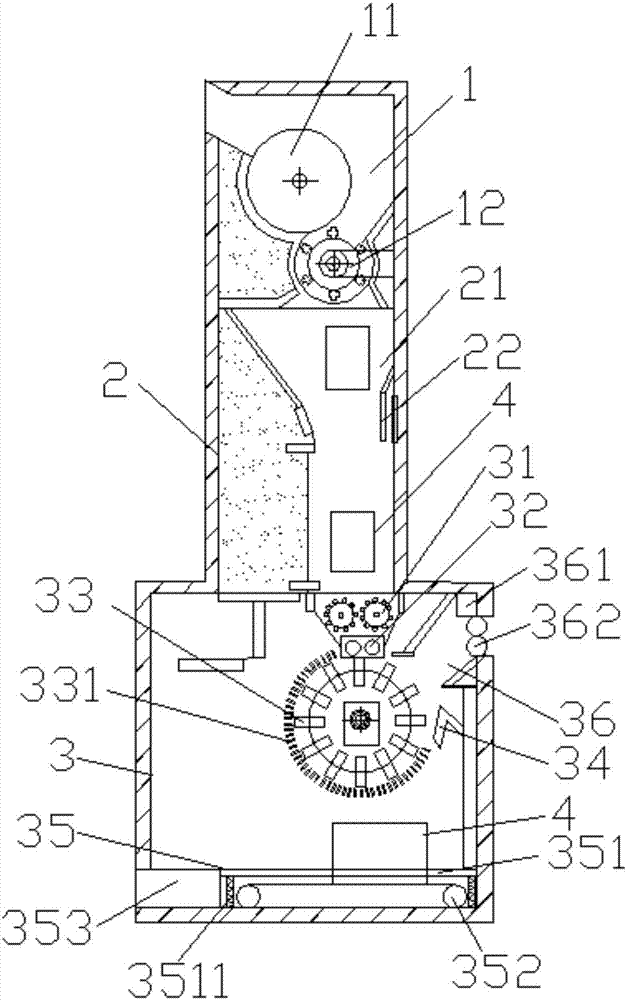

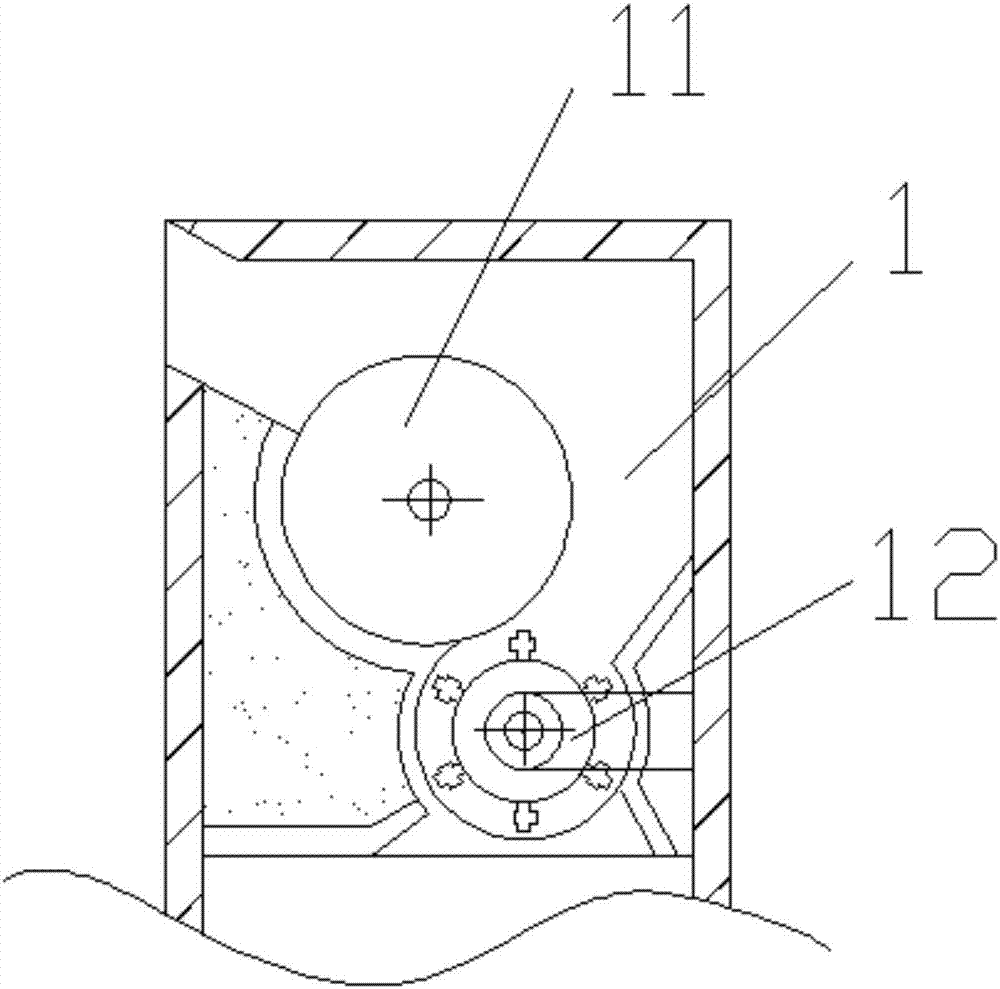

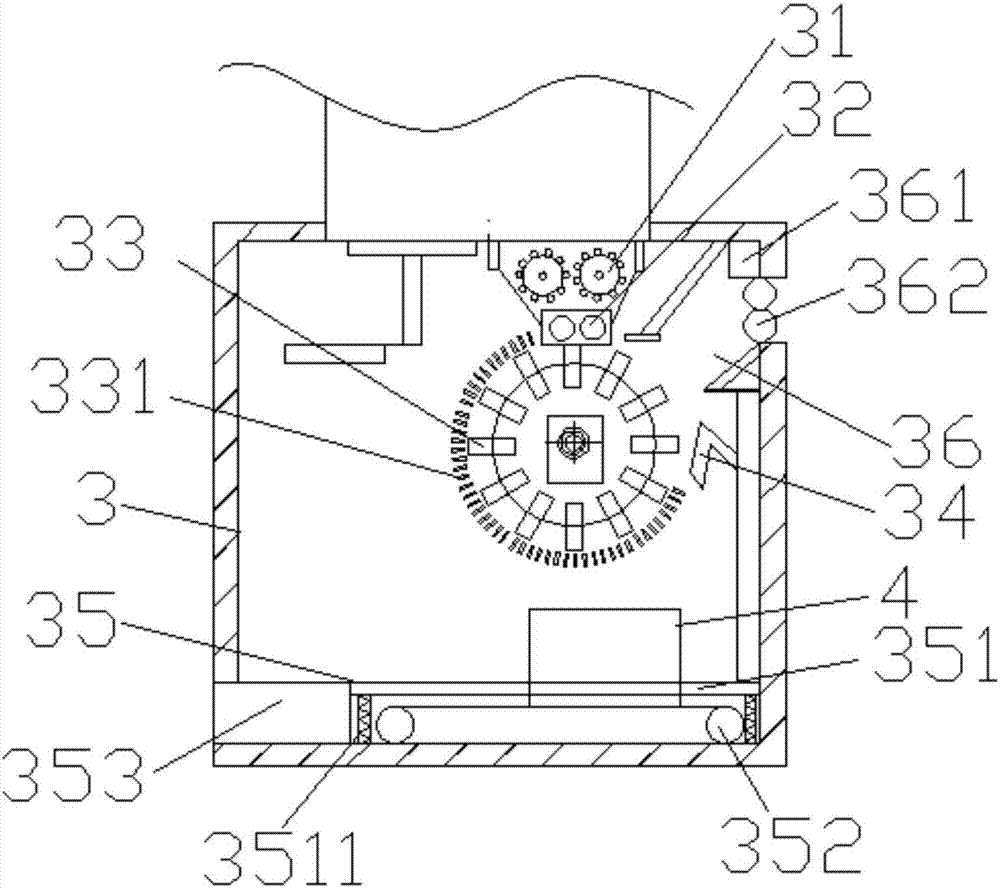

[0025] refer to Figure 1 to Figure 3 , the embodiment of the present application provides a card opener, including: a condenser 1, a transfer cotton box 2 and a cotton output box 3 connected in sequence;

[0026] The cotton condenser 1 is provided with a dust cage 11 and a cotton stripping beater 12, and the dust cage 11 is tangent to the cotton stripping beater 12;

[0027] Cotton condenser 1 is used in the process of opening and cleaning cotton, using the suction of the fan airflow to transport and condense the chemical fibers of the cotton block, and remove the short fibers, dust and impurities in the cotton flow.

[0028] The cotton condenser 1 is also equipped with a fan, and the raw cotton or chemical fiber is continuously condensed on the surface of the dust cage 11 under the action of the fan, and the dust, linters and impurities therein pass through the mesh plate of the dust cage 11 and fall through the fan. Into the dust passage, the raw cotton or chemical fiber c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com