Cotton fluffing equipment

A technology of fluffing and equipment, applied in the field of cotton fluffing equipment, can solve the problems of cotton flocs being easy to float, and achieve the effect of ensuring the safety of the body and improving the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

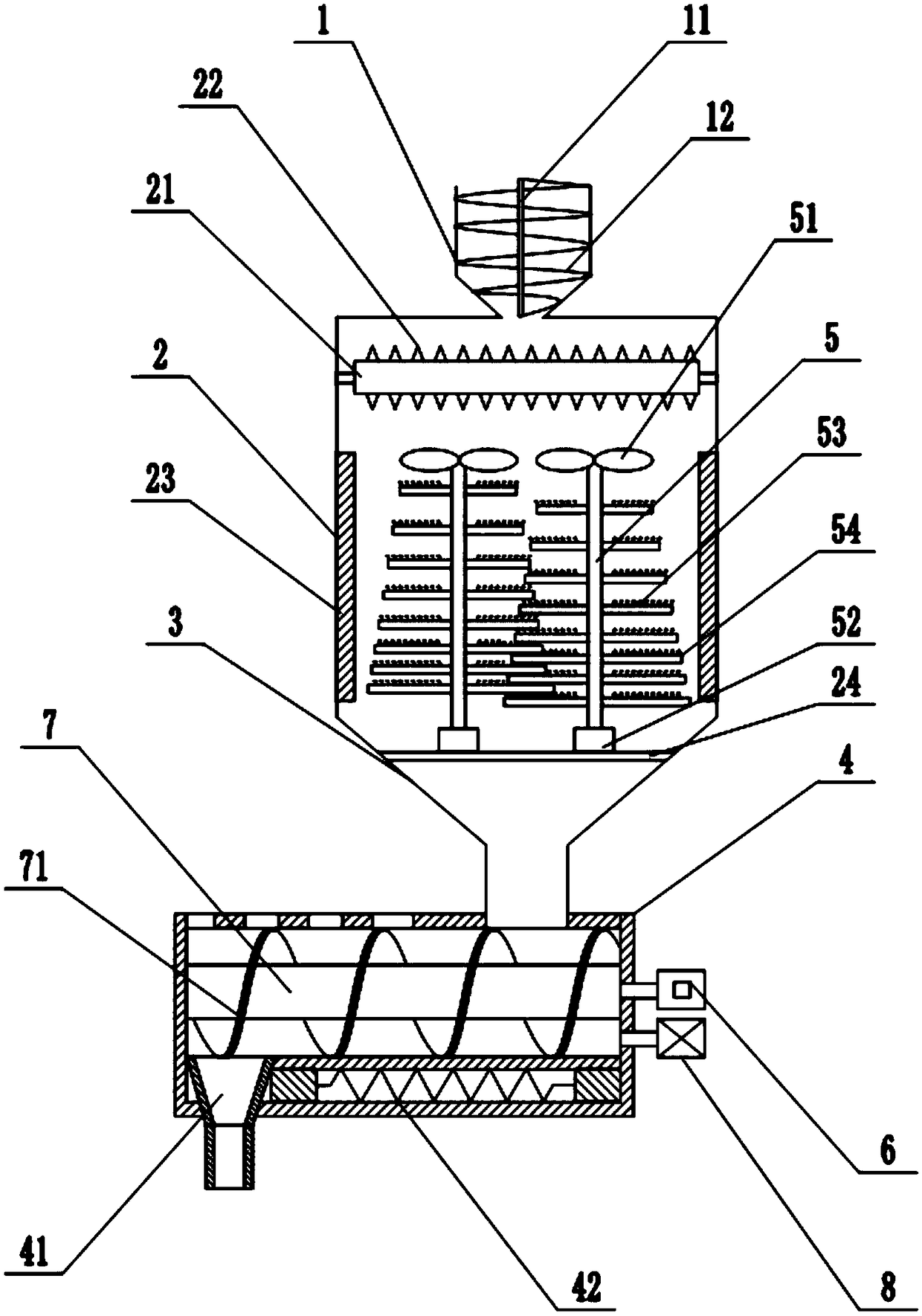

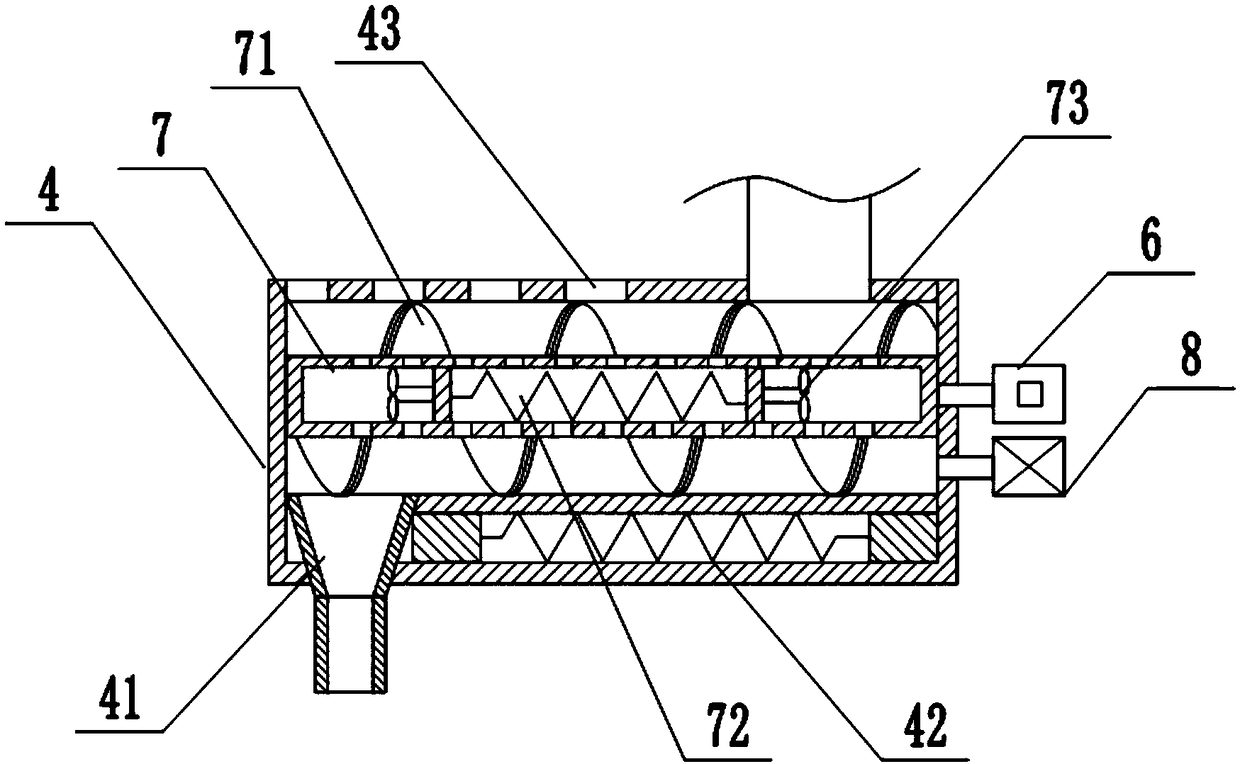

[0016] The reference signs in the drawings of the description include: feed hopper 1, rotating shaft 11, spiral blade 12, fluffy box 2, rotating roller 21, thorn head 22, electrostatic plate 23, bottom plate 24, conical guide hopper 3, discharge Device 4, hopper 41, first electric heating wire 42, air outlet 43, rotating rod 5, first rotating blade 51, first motor 52, fixed plate 53, hook 54, second motor 6, drum 7, Helical propulsion belt 71 , second electric heating wire 72 , second rotating blade 73 , fan 8 .

[0017] The embodiment is basically as attached Figures 1 to 2 Shown: a kind of cotton fluffing equipment, including feeding hopper 1, fluffing box 2, conical hopper 3 and discharge device 4, feeding hopper 1 is provided with a rotating base, and a rotating shaft 11 is fixedly connected to the rotating base, The rotating shaft 11 is provided with a helical bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com