Plucker roller for cotton feeder

A technology of opening roller and cotton feeding machine is applied in the field of cotton feeding machine to achieve the effects of reducing fire, high flexural strength and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

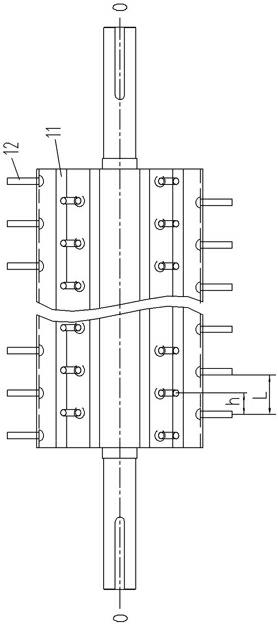

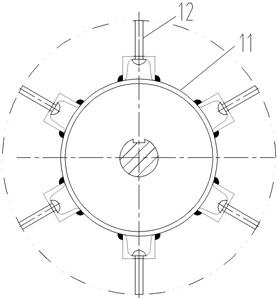

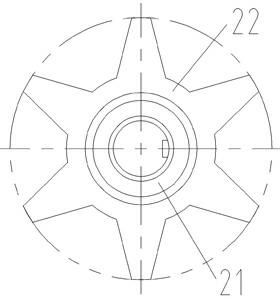

[0029] Such as image 3 and Figure 4 As shown, the main body of the opening roller of the cotton feeder is a drum 21, along the direction of the drum axis O-O, several J-angle star-shaped discs 22 with J points are arranged in sequence, wherein J is 6, 7 or 8, J=6 in this example. The rollers pass through the center of the disc in turn and fix the disc on it. The disc and the axis O-O have an angle α, 60°≤α≤80°, in this example α=77°. Taking a certain point on the axis O-O as the reference point, the inclination direction of the disk on one side of the reference point is exactly opposite to that of the disk on the other side. In this example, the number of disks on both sides of the reference point is 11 The axial spacing L of two adjacent discs on the same side as the reference point is equal, that is, the discs are arranged with equal axial distances. The distance occupied by each disc on the axis O-O is Y, and h2 h=100mm, and it is easy to mix in the seed cotton with ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com