Cotton slitter with inward wind blowing function

A cotton opener and internal air blowing technology, which is applied in the field of textile machinery, can solve problems such as difficult connection, large shape of the cotton opener, and affect the effect of opening cotton, and achieve good drying, compact structure, and good blowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment the present invention is further described:

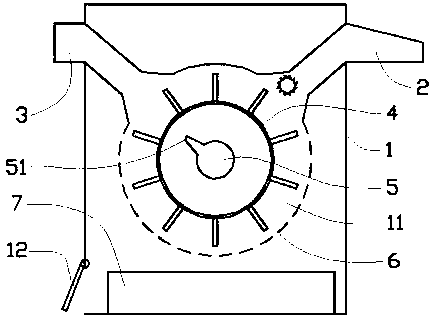

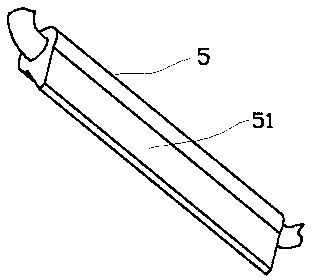

[0014] like figure 1 and figure 2 As shown in the embodiment, the internal blowing opener includes a frame box 1, a feed hopper 2, a discharge port 3, a beating roller 4, and a blowing pipe 5; the frame box 1 is in the shape of a cuboid, which is convenient for placement. Its inside is designed with a working chamber 11, the feed hopper 2 and the discharge port 3 are installed on the opposite surface of the rack box 1 respectively, and communicate with the working chamber 11, which is more convenient for other processing with the outside. mechanical connection. The beating roller 4 is installed in the working chamber 11, and vertical round rods are evenly distributed on its outer surface. The outer surface of the beating roller 4 uses a frame and barbed wire structure. The air supply device is connected, and the blowing pipe 5 is installed on the axis of the beating roller 4; the blow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com