Cotton opener

A cotton opener and frame technology, applied in the field of textile machinery, can solve problems such as low work efficiency, hairy sliver, and increased yarn hairiness, and achieve the effects of preventing loss and eliminating static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

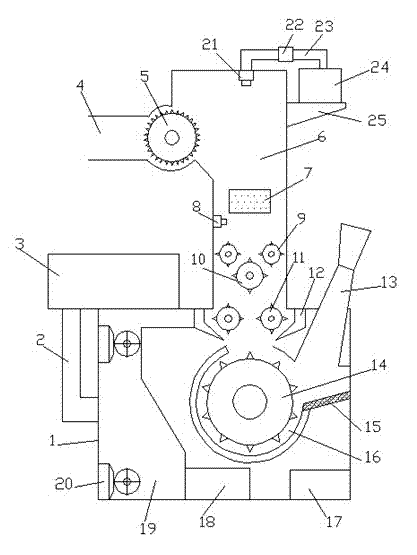

[0012] refer to figure 1 The cotton opener shown includes a frame 1, a cotton inlet 4 is arranged on the frame 1, a pre-opening device 5 is provided in the cotton inlet 4, and a cotton inlet is arranged behind the pre-opening device 5. box 6, the atomization nozzle 21 is arranged above the cotton inlet box 6, a photoelectric sensor 8 is arranged in the cotton inlet box 6, a small roller 9 is also arranged in the cotton inlet box 8, and an intermediate roller 10 is arranged below the small roller 9 , below the middle roller 10 is provided with a cotton feeding roller 11, and one side of the described cotton feeding roller 11 is provided with a baffle plate 12, and the bottom of the described baffle plate 12 is provided with an opening cavity 16, and the described opening cavity 16 is provided with an opening cylinder 14, and one end of the opening chamber 16 is provided with a filter plate 15, and the filter plate 15 forms a semi-closed space with the opening chamber 16, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com