Method for recovering copper and nickel from electroplating sludge

A technology for electroplating sludge and recovering copper, applied in the direction of improving process efficiency, can solve the problems of difficult implementation, long process route, unstable operation, etc., and achieve the effects of significant economic and social benefits, simple process, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

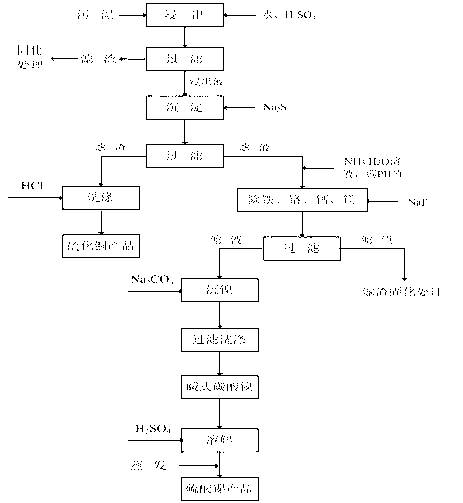

[0030] The process flow chart of this embodiment is as figure 1 As shown, its technological process is carried out in the following steps:

[0031] (1) Acid leaching: Slurry the electroplating sludge with a small amount of water, then slowly add sulfuric acid, control the pH value of the solution to 1.5, and the temperature is 20-40 ° C, leaching for 1-2 hours;

[0032] (2) Separation of copper and nickel: Add sodium sulfide to the acid leaching solution to separate copper and nickel. The amount of sodium sulfide added is 1.0-1.2 times the theoretical amount of copper precipitation, the temperature is maintained at 40-80°C, and the reaction time is 20-60 minutes;

[0033] (3) Filter, wash and dry the filter residue, combine the lotion and filtrate and transfer to the next process;

[0034] (4) Impurity removal: adjust the pH value of the solution to 5-7 with ammonia water to precipitate iron and chromium; heat the solution to 85-100°C, add a certain amount of sodium fluoride,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com