Method for recycling and synchronous harmless treatment of gold, silver and iron in roasting-cyanidation tailings

A cyanide tailings, harmless technology, applied in the field of metallurgical waste slag recycling, can solve the problems of complicated flue gas dust collection and purification process, heavy pollution, high treatment cost, and achieve the effect of harmless treatment and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The main chemical composition of a roasted cyanide tailings is: gold grade 3.62g / t, silver grade 53.79g / t, iron grade 26.43wt%, sulfur grade 1.02wt%, silica content 39.35wt%. The main metal mineral is hematite, containing a small amount of magnetite and pyrite, and the main gangue mineral is quartz.

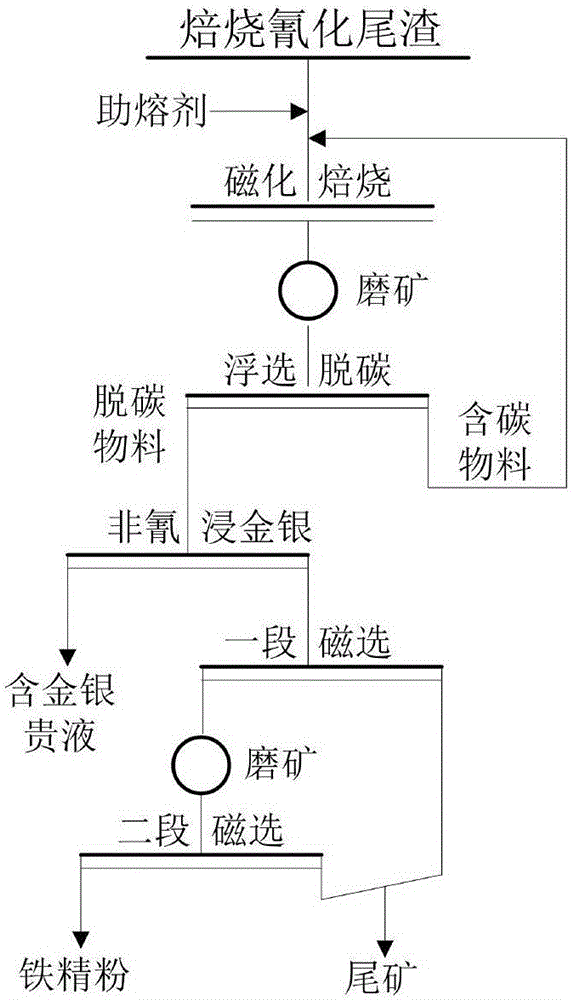

[0028] according to figure 1 The process shown is for recovery of gold, silver and iron and simultaneous harmless treatment. The specific steps are as follows:

[0029] (1) Add flux and magnetize roasting

[0030] Dry the roasted cyanide tailings at 90°C and break them up to obtain a dark red powdery material with a moisture content of 4.5wt%, -0.074mm 82%. The powdery material, sodium carbonate and bituminous coal are mixed in a mass ratio of 1:0.02: 0.25 and mix evenly, put it into a graphite crucible, reduce and roast in a box-type electric furnace at 800°C for 5 hours, and quench the calcine with water.

[0031] (2) Grinding - flotation decarburization

[0032] The...

Embodiment 2

[0039] The chemical composition of a roasted cyanide tailings is as follows: gold grade 5.26g / t, silver grade 68.24g / t, iron grade 32.85wt%, sulfur grade 0.91wt%, silica content 32.72wt%. The main metal mineral is hematite, and the main gangue mineral is quartz.

[0040] according to figure 1 The process shown is for recovery of gold, silver and iron and simultaneous harmless treatment. The specific steps are as follows:

[0041] (1) Add flux and magnetize roasting

[0042] Dry the roasted cyanide tailings at 80°C and break them up to obtain a dark red powdery material with a moisture content of 4.1wt% and -0.074mm accounting for 85%; the powdery material is mixed with sodium nitrate and bituminous coal at a mass ratio of 1:0.015 : 0.20, mix evenly, put it into graphite crucible, reduce and roast in box-type electric furnace at 750°C for 4 hours, and quench and cool the calcined sand.

[0043] (2) Grinding - flotation decarburization

[0044] The water-quenched calcine is ...

Embodiment 3

[0051] The chemical composition of a roasted cyanide tailings is as follows: gold grade 2.78g / t, silver grade 41.37g / t, iron grade 36.59wt%, sulfur grade 1.38wt%, silica content 30.48wt%. The main metal mineral is hematite, containing a small amount of magnetite, the main gangue mineral is quartz, and a small amount of feldspar and mica.

[0052] according to figure 1 The process shown is for recovery of gold, silver and iron and simultaneous harmless treatment. The specific steps are as follows:

[0053] (1) Add flux and magnetize roasting

[0054] Dry the roasted cyanide tailings at 85°C and break them up to obtain a tailings material with a moisture content of 3.8wt% and -0.074mm accounting for 88%; the tailings material is mixed with sodium sulfate and lignite in a mass ratio of 1:0.025:0.30 Mix evenly, put it into a graphite crucible, reduce and roast it in a box-type electric furnace at 850°C for 4 hours, and quench the calcine with water.

[0055] (2) Grinding - flot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com