Comprehensive utilization method for aluminum oxide red mud

A technology of alumina and red mud, which is applied in the fields of metallurgy and environmental protection, can solve the problems of insufficient utilization of red mud, land occupation, environmental pollution, etc., and achieve the effect of harmless treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

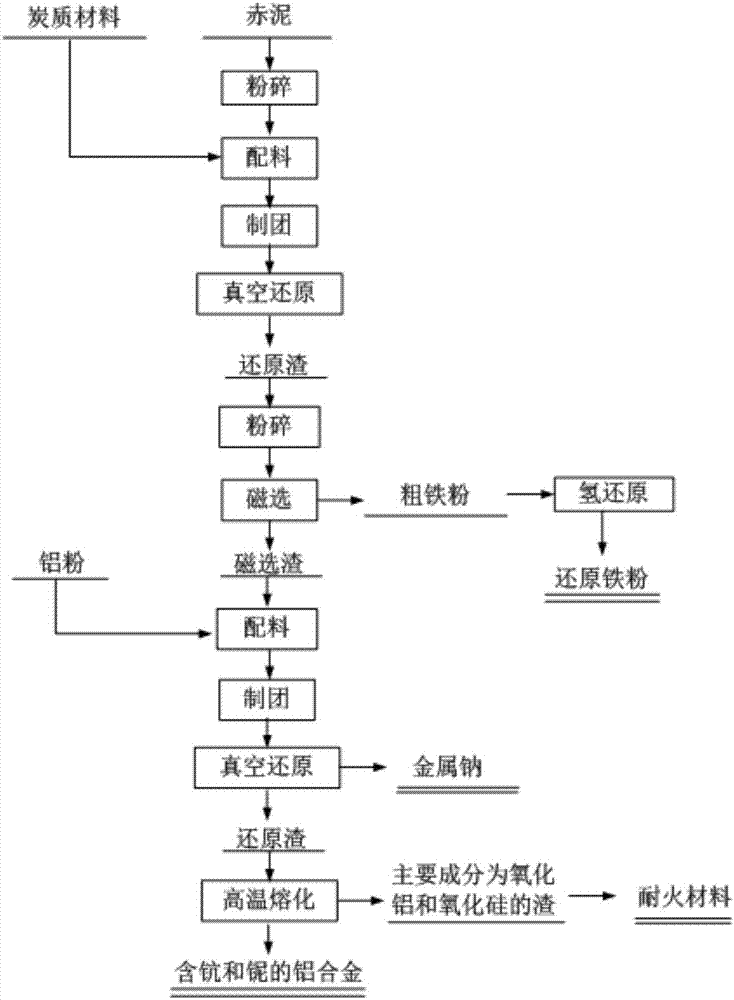

[0094] Such as figure 1 As shown, the comprehensive utilization method of alumina red mud in this embodiment is as follows:

[0095] Take 1000g of alumina red mud, dry it at 200°C for 2 hours, then calcinate at 700°C for 2 hours, crush the calcined red mud to 100 mesh, and then mix it with 100 mesh carbon powder , under the pressure of 60MPa, the agglomeration is made, and the amount of carbon powder is mixed according to 100% of the theoretical amount. Put the prepared agglomerate into a vacuum reduction tank, put the vacuum reduction tank into a heating furnace and heat it to 1000°C, and carry out vacuum thermal reduction under the condition of a vacuum degree of 20Pa. After the reduction, the reduction slag was ground to 100 meshes and then subjected to magnetic separation. The slag (coarse iron powder) obtained by the magnetic separation was reduced by hydrogen to obtain 200 g of reduced iron powder, and the purity of the reduced iron powder reached 98 wt%.

[0096] Grin...

Embodiment 2

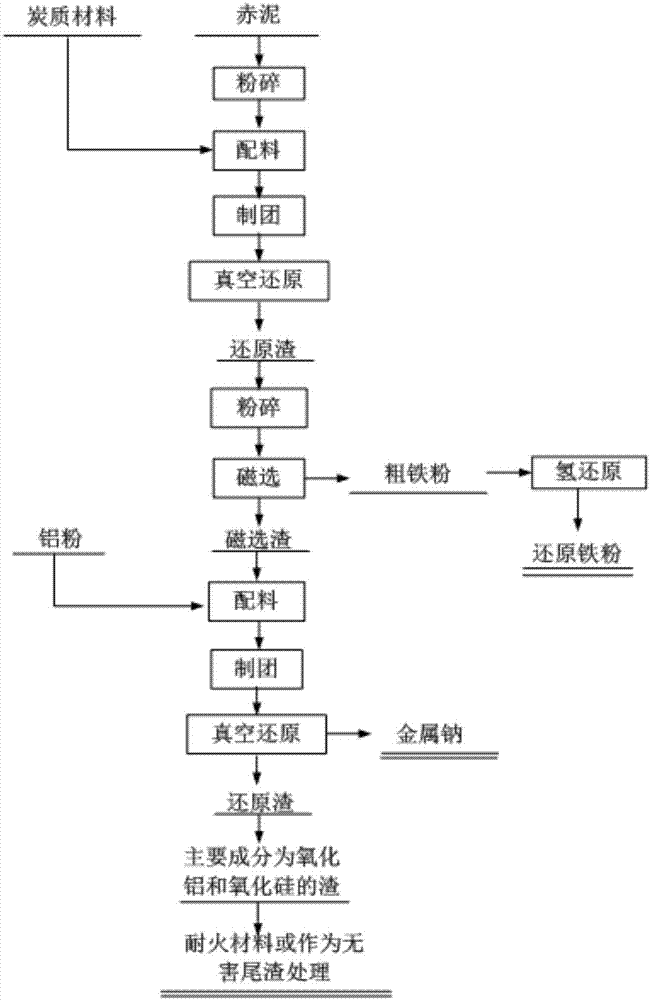

[0098] Such as figure 2 As shown, the comprehensive utilization method of alumina red mud in this embodiment is as follows:

[0099] Take 1000g of alumina red mud, dry it at 200°C for 3 hours, then calcinate it at 700°C for 2 hours, crush the calcined red mud to 100 mesh, and then mix it with 100 mesh carbon powder , under the pressure of 60MPa, the agglomeration is made, and the amount of carbon powder is mixed according to 100% of the theoretical amount. Put the prepared agglomerate into a vacuum reduction tank for reduction, put the vacuum reduction tank into a heating furnace and heat to 850°C, and perform vacuum thermal reduction under the condition of a vacuum degree of 1Pa. After the reduction, the reduction slag was ground to 100 meshes and then subjected to magnetic separation. The slag (coarse iron powder) obtained by the magnetic separation was reduced by hydrogen to obtain 200 g of reduced iron powder, and the purity of the reduced iron powder reached 98 wt%.

...

Embodiment 3

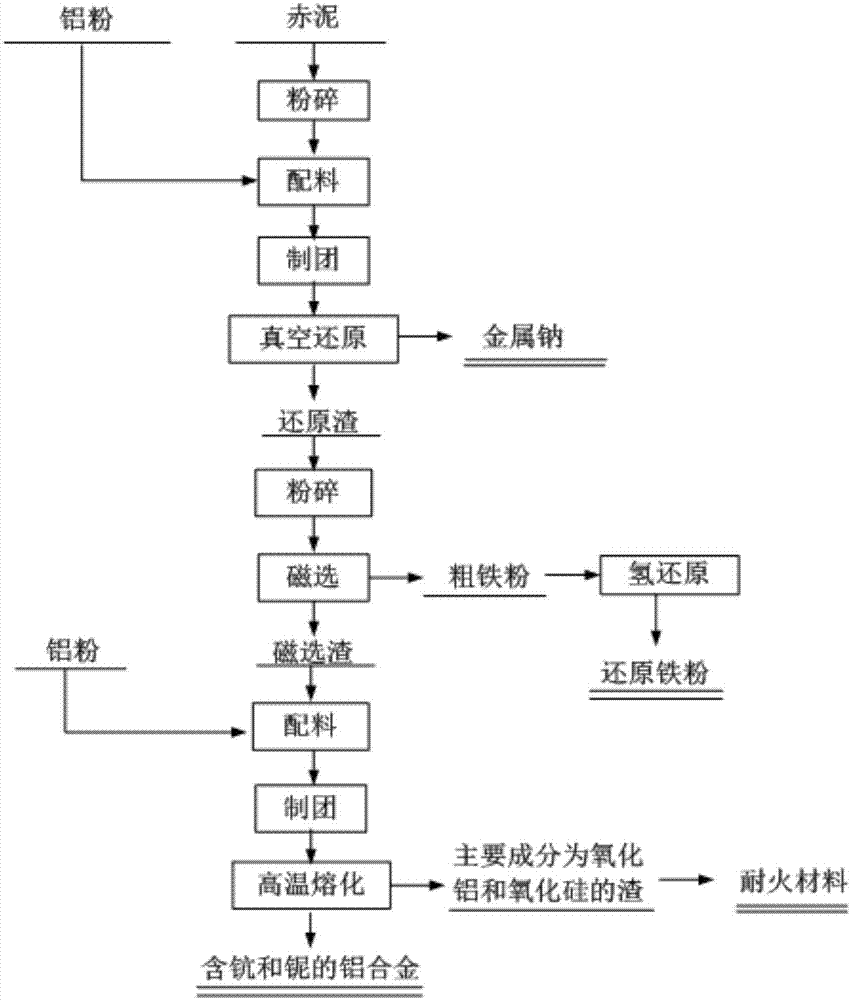

[0102] Such as image 3 As shown, the comprehensive utilization method of alumina red mud in this embodiment is as follows:

[0103] Take 1000g of alumina red mud, dry it at 200°C for 3 hours, then calcinate it at 600°C for 2 hours, crush the calcined red mud to 100 mesh, and then mix it with 100 mesh aluminum powder , the amount of aluminum powder added is 200 grams, the mixed material is made into agglomerates under a pressure of 60MPa, the prepared agglomerates are put into a vacuum reduction tank for reduction, and the vacuum reduction tank is put into a heating furnace and heated to 950°C. Vacuum thermal reduction is carried out under the condition that the degree of vacuum is 5Pa. After the reduction, 130 grams of sodium metal was collected on the crystallizer, and the crystallizer together with the sodium crystallized on it was put into another corundum crucible in a vacuum furnace and melted at a temperature of 300°C and a vacuum of 1Pa , and then break the vacuum to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com