System and method for achieving flexible operation of circulating fluidized bed boiler based on acoustic wave technology

A circulating fluidized bed and flexible technology, applied in the field of circulating fluidized bed boiler power generation, can solve the problems of difficult to achieve flexible operation and single means, so as to reduce the fly ash combustible index, increase the cycle rate, and improve the combustion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

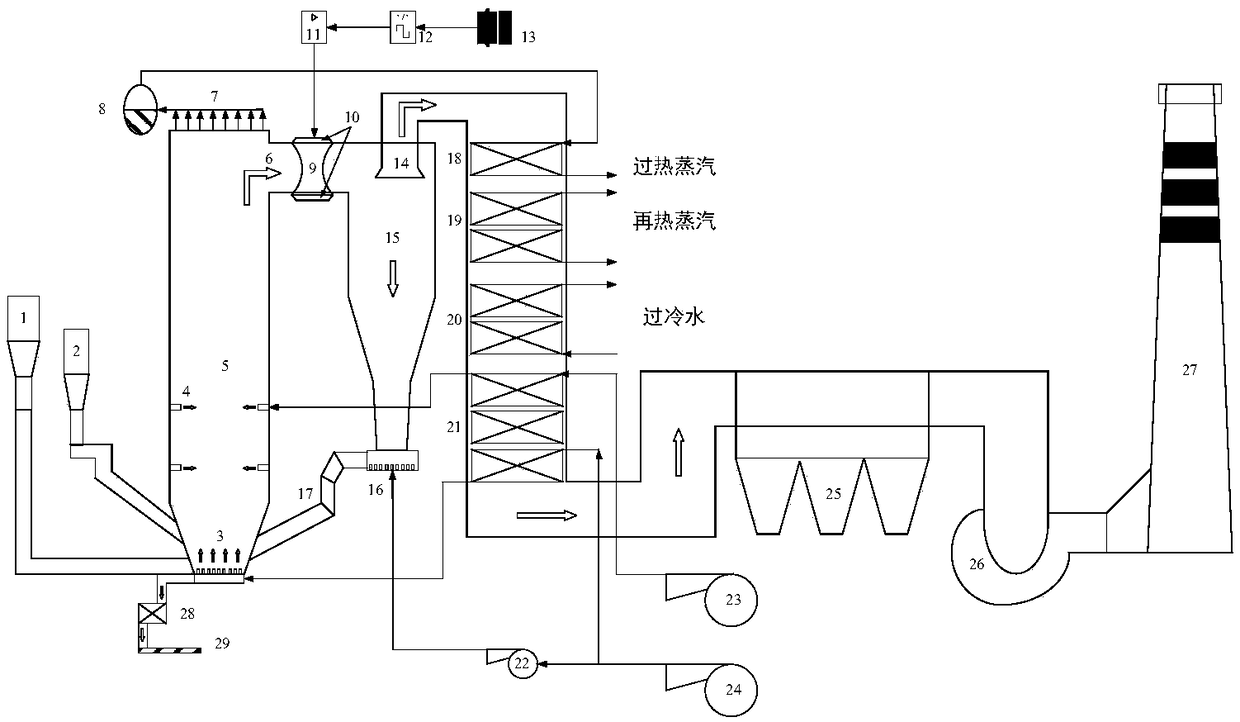

[0029] Such as figure 1 and figure 2 As shown, the present invention provides a system for realizing the flexible operation of a circulating fluidized bed boiler based on sound wave technology, including a circulating fluidized bed boiler and a sound wave emitting device, wherein the sound wave emitting device is used to control the flow into the circulating fluidized bed boiler The particle size distribution of the dust, and then control the circulation rate of the circulating fluidized bed boiler; and then determine the operation mode of the circulating fluidized bed boiler as the flexible adjustment simulation operation mode or the original mode safe operation mode.

[0030] Among them, the circulating fluidized bed boiler includes a limestone powder feeding device 1, a coal feeding device 2, a primary tuyere 3, a secondary tuyere 4, a furnace 5, a horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com