Dense-phase conveying-bed coal pressurizing gasifying apparatus and method

A technology of pressurized gasification and transport bed, applied in the field of coal gasification, can solve the problems of low investment and achieve the effects of improving removal efficiency, preventing coking and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

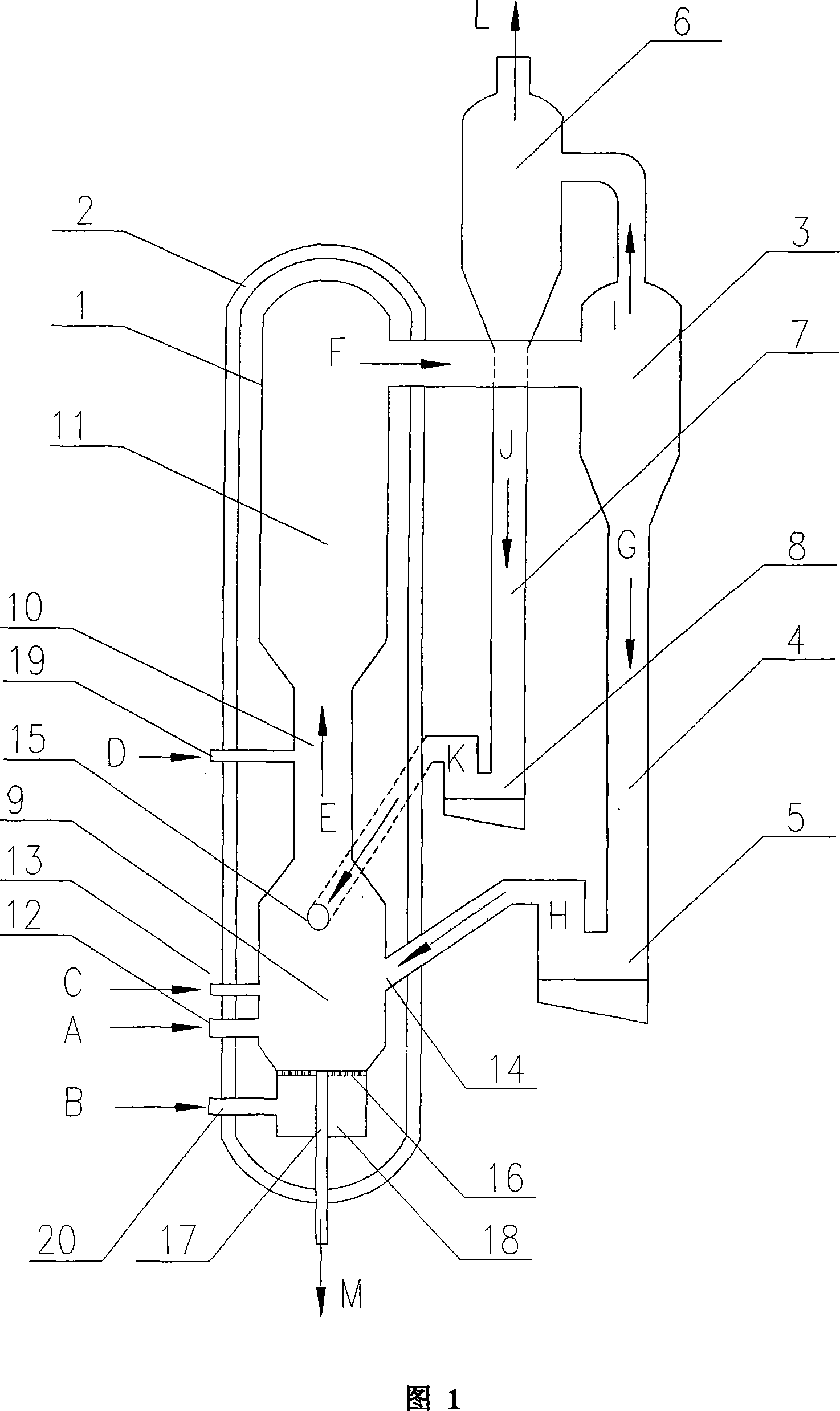

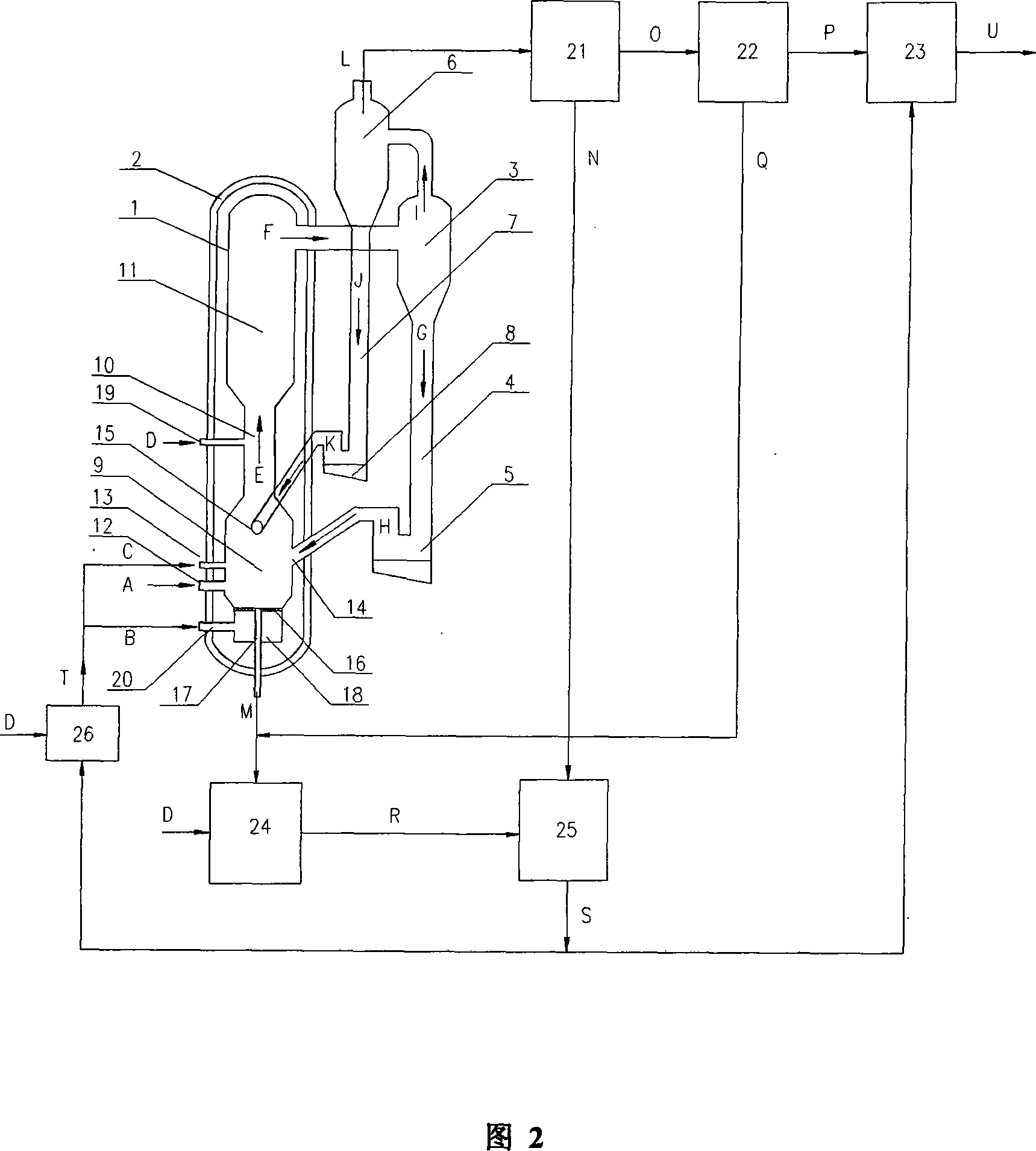

[0021] See attached drawing 1. Gasification reactor 1 is divided into three sections: mixing section 9, lifting section 10 and conveying section 11. The same high operating pressure of 2.0-3.0 MPa, medium-high temperature operating temperature of 1000-1100°C and solid flux are adopted. More than 200kg / m 2 s dense-phase transport flow regime, but operating at different speeds. The mixing section 9 adopts a low flow rate operation mode of 2.5-4.5m / s, and its function is to achieve good mixing of coal and limestone A, gasification agent T and primary and secondary return materials, as well as coal devolatilization, combustion and Partial gasification reaction; in order to realize this function, a certain amount of inert bed material with appropriate particle size, such as quartz sand, is added in the mixing section 9 to ensure that a dense phase area is formed at the bottom of the mixing section 9; Fine coal particles; the gasification agent T is formed by mixing superheated ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com