Homogeneous flow-field circulating fluidized bed flue gas desulfurization technology

A circulating fluidized bed and flue gas technology, applied in chemical instruments and methods, dispersed particle separation, lighting and heating equipment, etc., can solve the problems of large reactor resistance drop, uneven flow field, low desulfurization efficiency, etc. Improve the reactivity, solve technical problems, and ensure the effect of desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

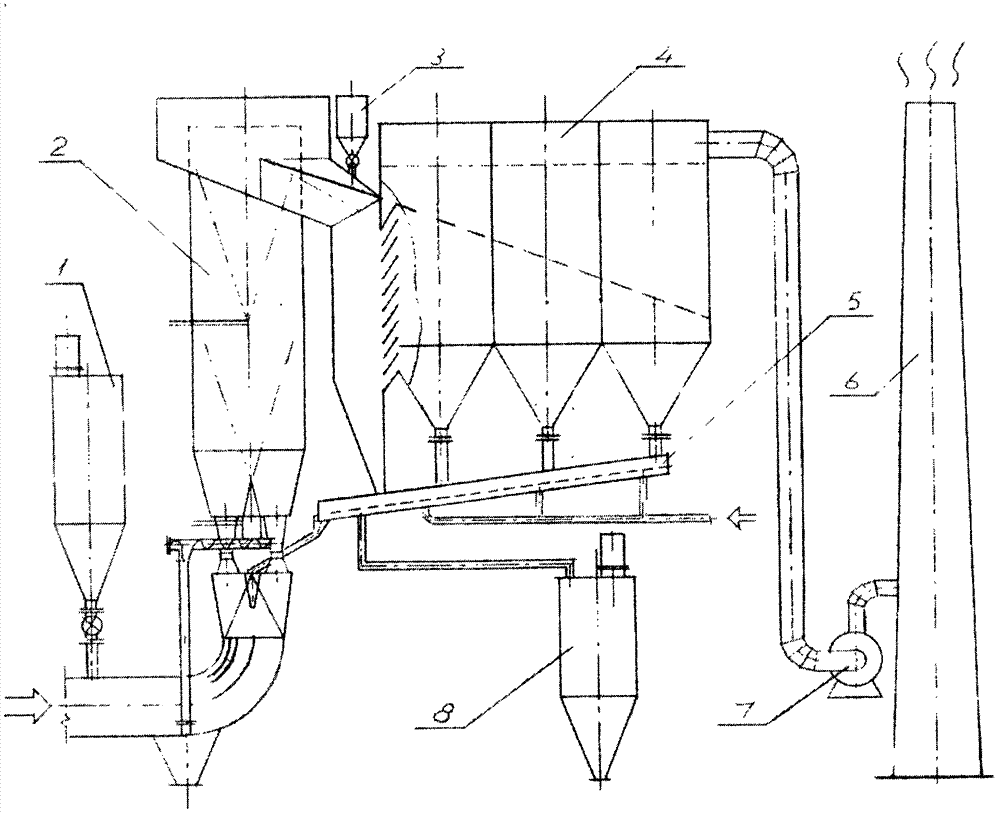

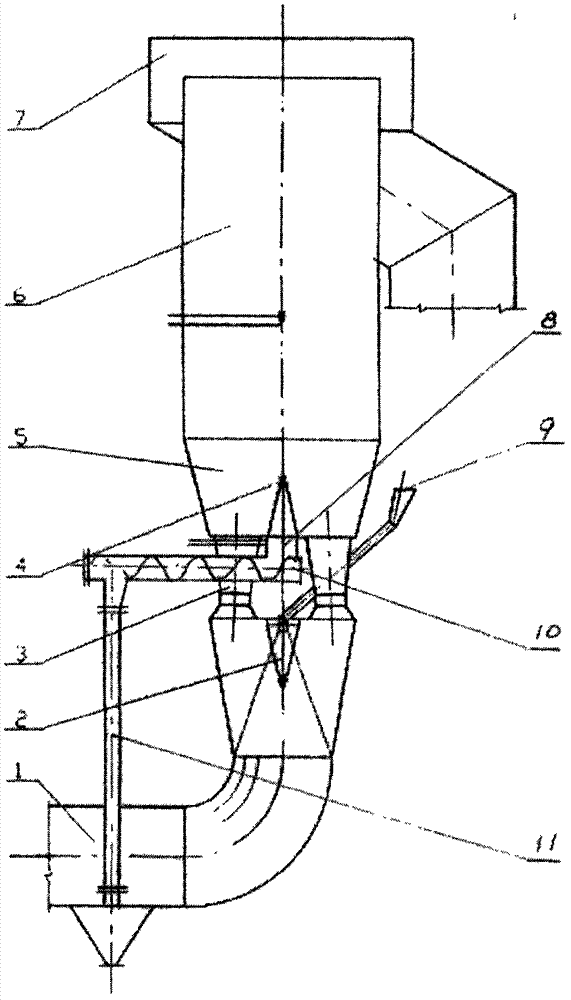

[0050] See figure 1 , Containing SO x , HCl, HF, NO x Boiler flue gas with pollutants such as dust enters the reactor 2 through the flue gas inlet flue. Used to remove SO x The slaked lime of acid gas such as HCl, HF, etc. is sent into the flue gas inlet flue by the star feeder at the bottom of the slaked lime bin. The inlet flue gas with a flow rate of ~16m / s sends the slaked lime and the circulating ash from the outlet of the absorbent distributor into the flue gas and absorbent accelerator. The flue gas, the slaked lime and the circulating ash are instantly accelerated and mixed uniformly. At this time, the humidification activation nozzle located at the bottom of the center of the reactor cylinder uniformly sprays water mist with extremely fine droplet size (40-60 μm), and the water mist rapidly mixes and evaporates with the flue gas surrounded by high-temperature flue gas ( Generally, it takes 1 to 3 seconds). While the ionic deacidification reaction is completed instantly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com