Fused magnesium molten lump waste heat utilizing method and system

A technology of electric fused magnesium and magnesium fused lumps, which is applied in steam applications, steam engine devices, machines/engines, etc., can solve problems such as unstable heat sources, and achieve the effects of improving waste heat recovery efficiency, reducing large fluctuations, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

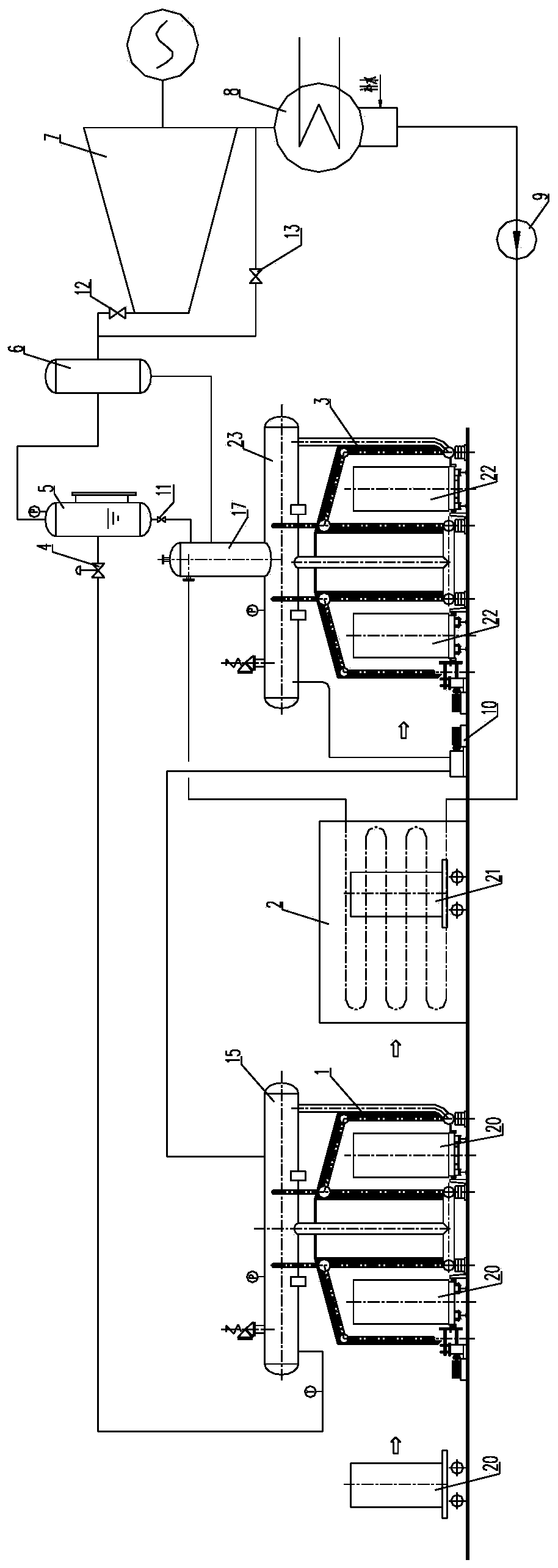

[0028] Such as figure 1 As shown, the method for utilizing the waste heat of the fused magnesium fused lump described herein comprises the following steps:

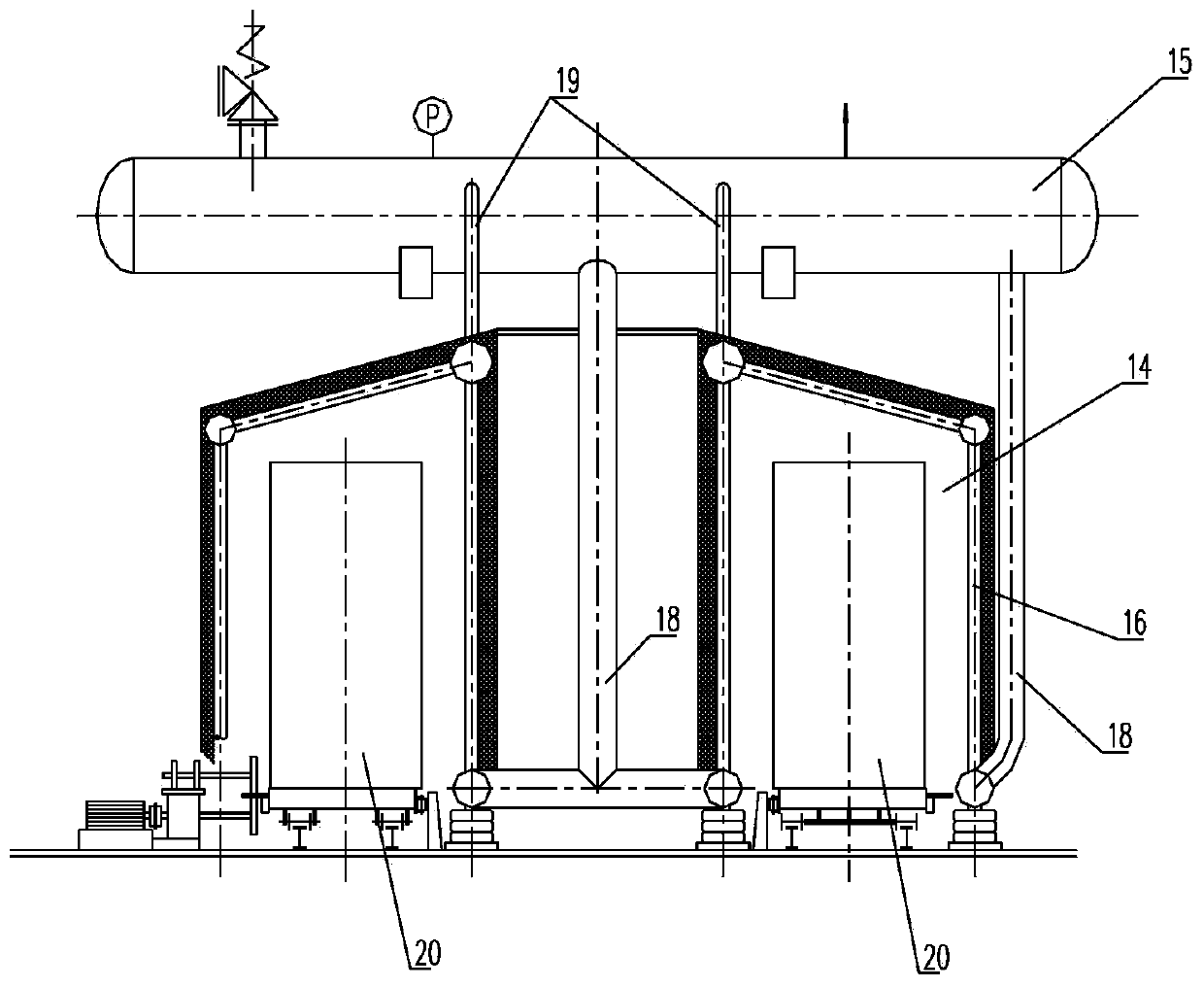

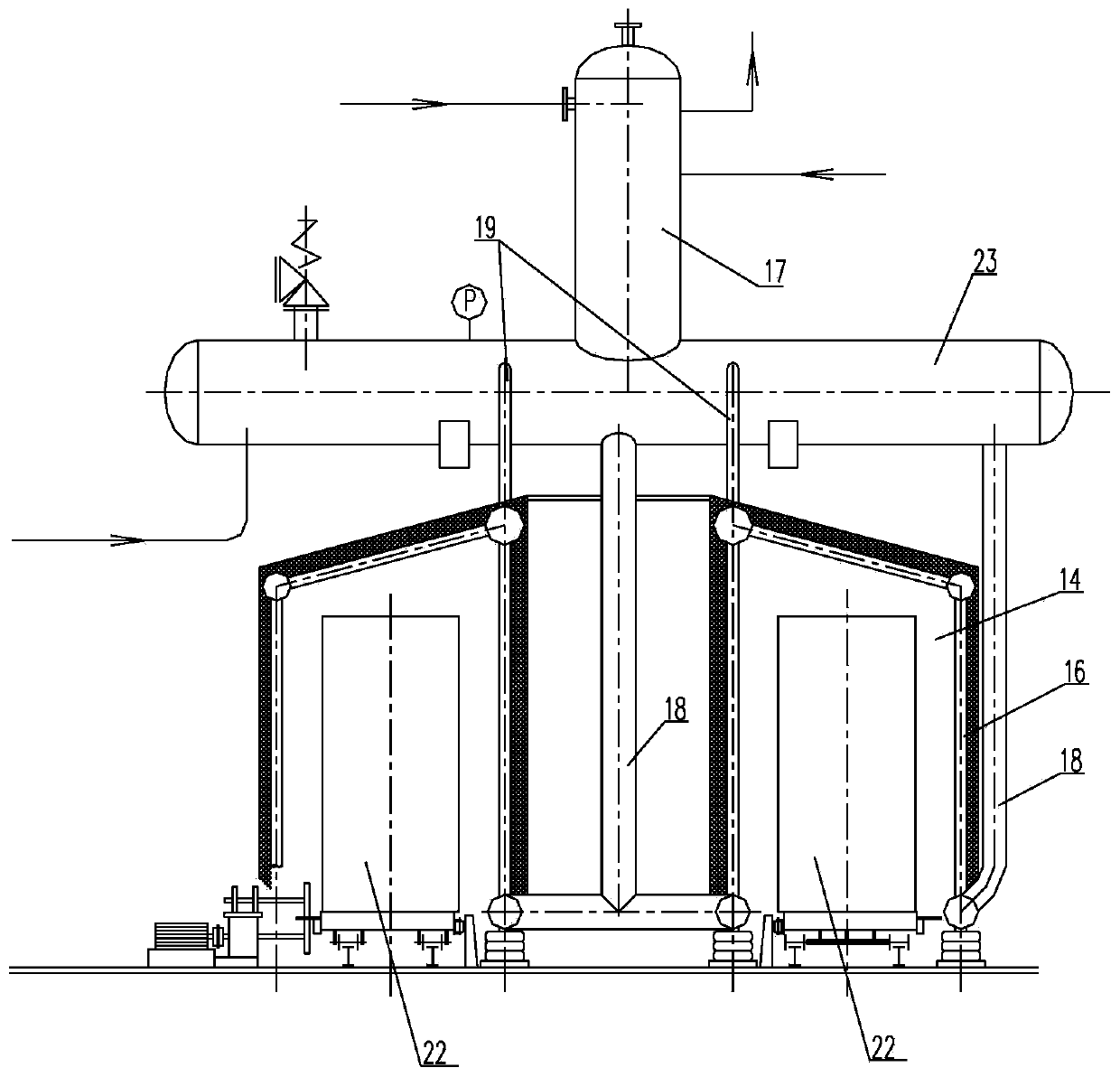

[0029] 1) The molten electric fused magnesium frit 20 is sequentially sent to the molten magnesium frit waste heat recovery chamber 1, the broken shell magnesium frit waste heat recovery chamber 2, and the self-deoxidizing magnesium frit waste heat recovery chamber 3 to respectively recover waste heat, recover waste heat and cool The final fused magnesium fused lump is sent to the next process;

[0030] 2) The condensed water of steam turbine 7 below 40°C is sent to the waste heat recovery chamber 2 of the shell-cracked magnesium fused mass, and is heated to above 80°C after exchanging heat with the electric fused magnesium fused mass 21 in shelling, and then sent to the self-deoxidizing mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com